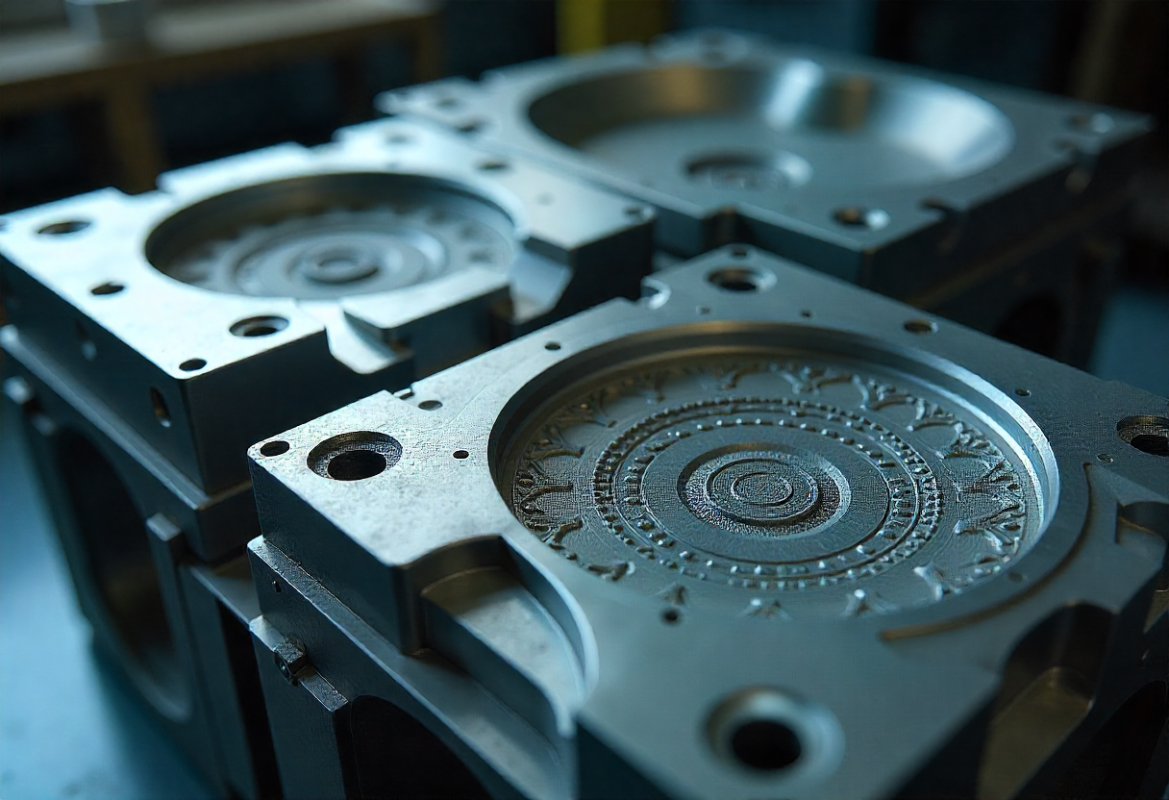

Tooling Overview From Prototype Dies to Production Molds & Fixtures

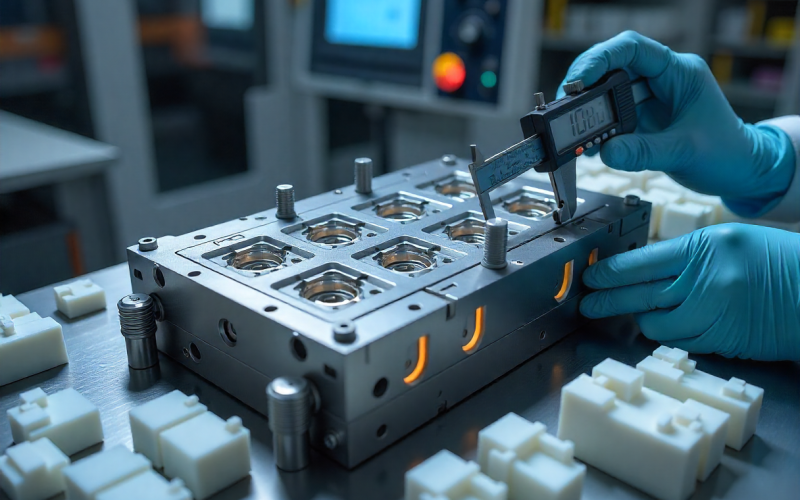

Complete tooling capability: prototype & production injection molds, die casting dies, rubber & LSR molds, extrusion dies, progressive stamping tools, casting patterns, and precision jigs & fixtures — engineered for quality, repeatability and long life.

- End‑to‑end tooling: CAD → CAM → tool build → tryout → validation → lifecycle support

- Tooling strategies for cost amortization, multi‑cavity optimization and rapid NPI

- Maintenance, spare components, refurbishment and emergency repair programs

Injection Molds — Prototype & Production

Die Casting Dies — Vacuum & Low Pressure

Progressive Stamping & Progressive Tooling

Tool Types & Where We Use Them

Injection Molds (Prototype & Production)

Die Casting Dies (Aluminum / Zinc)

Rubber & LSR Molds

Extrusion Dies & Co‑extrusion Tooling

Progressive & Transfer Stamping Dies

Casting Patterns & Molds

Tool Design & Engineering Process

We follow a structured tooling development process to align cost, performance and launch schedule:

- Requirement capture — part function, volumes, tolerances, surface and finish expectations

- DFM & tooling strategy — prototype vs production tooling, cavity count, hot runner, family/family tools

- Tool design — CAD, cooling, gating, venting, ejector systems, wear surfaces and fixture interfaces

- CAM & build — EDM, CNC, polishing, hardening and assembly

- Tryout & validation — first article, process window, cycle optimization and sample approval

- Lifecycle handover — maintenance schedules, spare parts, tooling drawings and PM plans

Design for Tool Life & Cost

Tool materials, surface treatments, coating (TiCN/TiN), and heat treatment schedules are selected to balance tool life and upfront cost. Multi‑cavity tooling reduces piece cost but increases initial tooling cost — we provide amortization models to help decide the best path.

Tool Life, Maintenance & Repair Programs

Preventative Maintenance

Scheduled inspections, dimensional checks, polish cycles, cooling channel cleaning, and parting line adjustments. We log PM activities and issue tool status reports to customers.

Repair & Refurbishment

EDM rework, inserts replacement, resurfacing, re‑polish and re‑hardening. Emergency repair lanes for minimized downtime and rapid turnaround for critical tools in production.

Spare Parts & Redundancy

We recommend spares for critical wear items (cores, inserts, slides) and offer die leasing or shared ownership models to reduce customer CAPEX while protecting production continuity.

Tryout, Validation & Quality Gates

First article tryout includes dimensional inspection (CMM), sample surface finish checks, mechanical tests and process window definition. For regulated industries we integrate FAI/PPAP protocols, capability studies (Cpk) and traceable sample records.

Tryout deliverables

- FAI report and sample parts

- Process window (temperatures, cycle times, cooling profiles)

- Tooling acceptance checklist and operator instructions

- SPC plan and recommended inspection frequency

Tooling Cost Models & Amortization

Prototype (aluminum)

Low CAPEX, quick turnaround — ideal for validation and small runs

Production (hardened steel)

Higher CAPEX, long tool life — optimal for high volumes

Multi‑cavity

Lower piece cost, higher tool cost — consider volume and cycle time

Service & spares

Planned spare strategy minimizes line stoppage risk

Tool Materials & Surface Treatments

Representative Tooling Projects

16‑Cavity PEEK Connector Mold