Mold Capabilities — Injection, Die Casting, LSR, Extrusion & Stamping

Detailed capabilities for prototype and production tooling. We design, build, try out and support molds and dies across multiple processes with attention to tool life, maintainability and cost amortization.

- Prototype → production tooling strategies (aluminum prototype, hardened steel, multi‑cavity)

- Specialty tooling: hot runner, valve gate, family molds, cavity inserts, and co‑injection

- Lifecycle services: PM, spares, repair, refurbishment and emergency lanes

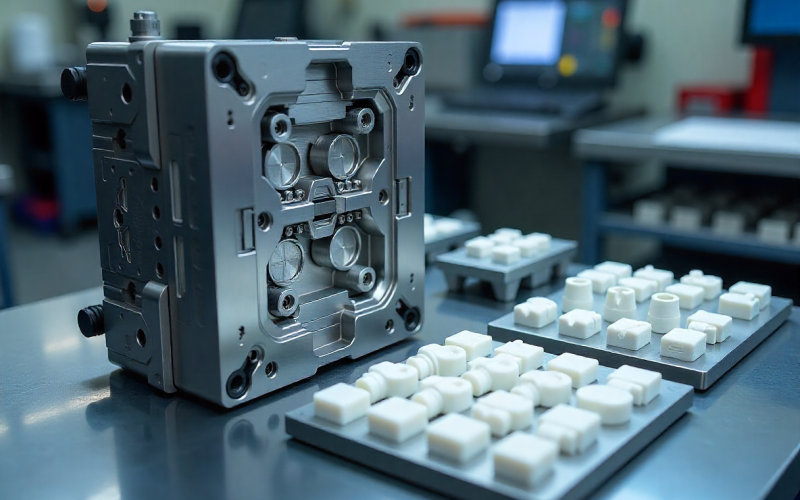

Injection Molds — Prototype & Production

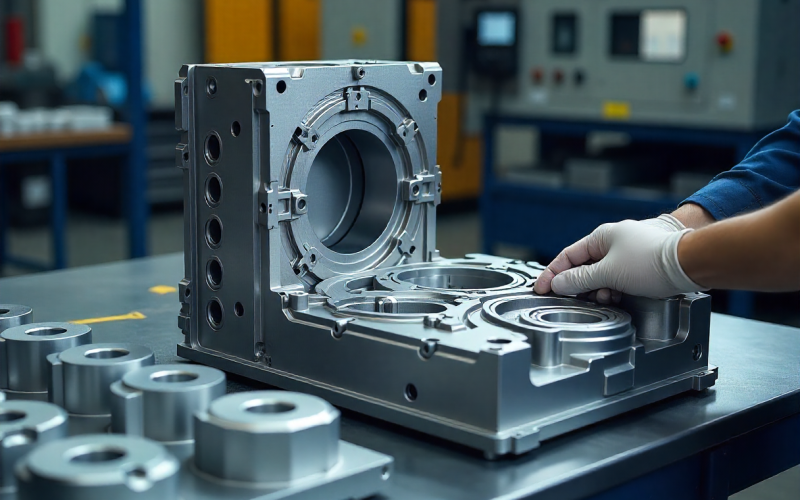

Die Casting Dies — Aluminum & Zinc

LSR & Rubber Molds

Injection Mold Capabilities

Key features

Tryout & validation

Die Casting Die Capabilities (Aluminum / Zinc)

Process & tooling features

Rubber & LSR Mold Capabilities

Highlights

- Metering and shot traceability for LSR process control

- Insert & overmold capabilities combining elastomer with rigid substrates

- Cleanroom molding readiness and medical‑grade tooling options

Extrusion Die Design & Tooling

Capabilities

- Co‑extrusion for multi‑durometer or bonded profiles

- Die maintenance programs and spare landings

- Cut‑to‑length automation and downstream machining integration

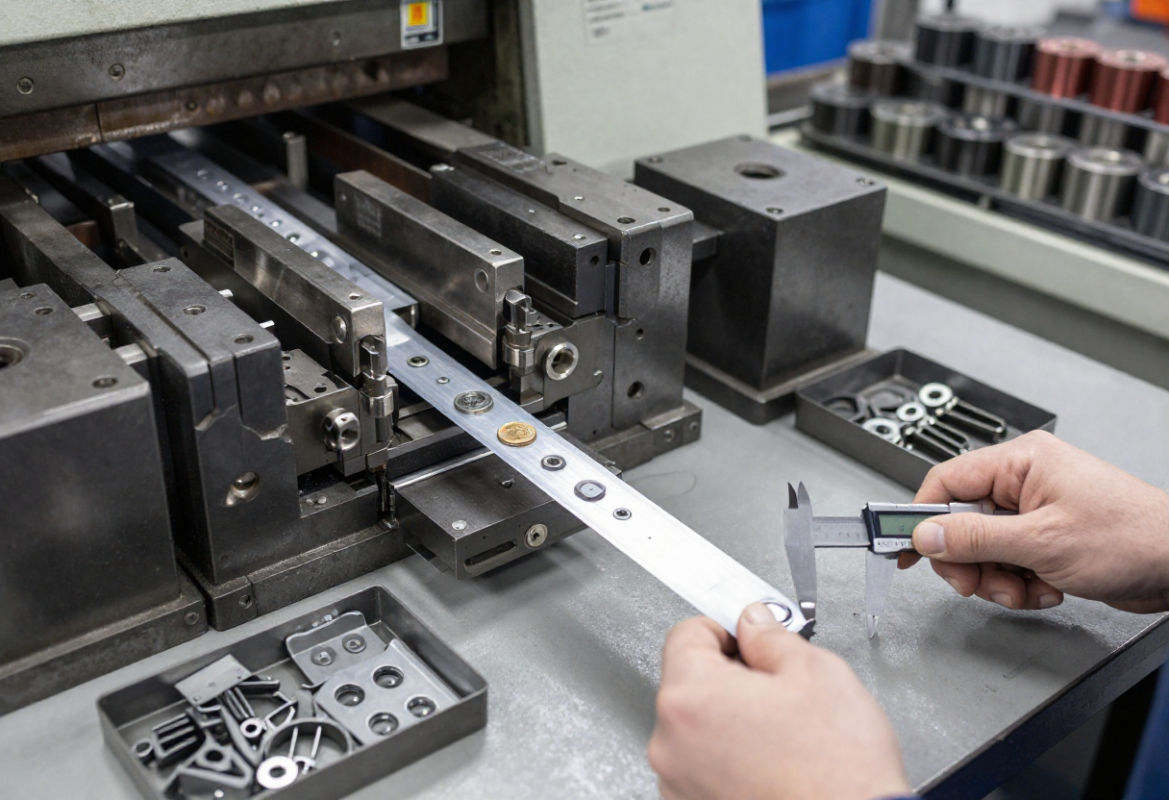

Progressive & Transfer Stamping Tooling

Engineering focus

- Strip & blank optimization, material utilization

- Progressive station design to balance forming and reduce scrap

- In‑die quality checks and automated ejection systems

Casting Patterns & Forging Dies

Additions

- Investment & sand pattern fabrication with rapid prototyping

- Forging die flow and flash trimming plan with heat treatment post‑process

- NDT readiness (CT/X‑ray and ultrasonic) for critical castings

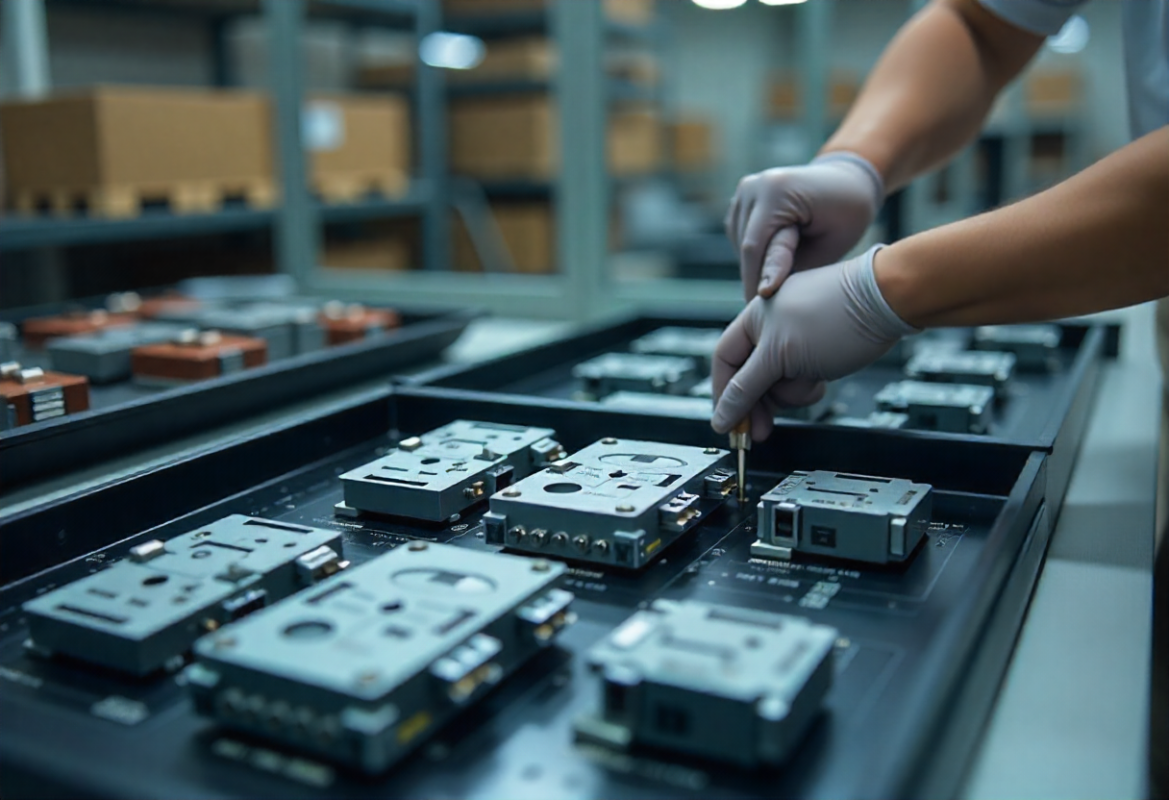

Jigs, Fixtures & Welding / FSW / Laser Fixtures

Typical features

- Quick change pallets, locator pins and datum references

- Integrated temperature or pressure sensors for process monitoring

- Robotic end‑effector interfaces and safety interlocks

Tool Life, Maintenance & Repairs

Preventative maintenance

Regular dimensional checks, coolant channel cleaning, polish cycles and functional run checks recorded in tooling logs and recommended PM intervals tied to shot counts

Repair & refurbishment

EDM, welding rebuilds, recoating (TiCN/TiN), re‑hardening and resurfacing to restore tool functionality and extend lifecycle.

Tryout, First Article & Quality Gates

Typical tryout deliverables

- FAI report with dimensional CMM data

- Sample gallery and surface finish verification

- Process window and initial SPC plan

- Tool acceptance checklist and maintenance recommendations

Tool Materials & Surface Treatments

Standard tool steels (P20, H13, S7) are selected per application with nitriding or cryo treatments where beneficial. Surface coatings (TiN, TiCN) and nickel plating for cooling passages increase wear resistance and corrosion protection. We specify treatments based on run rates, abrasive plastics and environmental exposure.

P20

General purpose, pre‑hardened steels for injection mold bases

H13

Hot work steel for core/cavity demanding thermal cycles

S7

Shock resistant tool steel for progressive dies and impact work

Coatings

TiN/TiCN, DLC, nickel plating for channels and wear surfaces

Quality, Testing & Inspection

Regulatory & traceability

Finishing, Decoration & Assembly

Packaging & global fulfillment

Tooling Cost Models & Amortization

| Tool Type | Typical Tool Cost | Shot Life / Notes |

|---|---|---|

| Aluminum prototype mold | Low (USD thousands) | Quick turn; limited life; best for validation |

| Hardened steel injection mold | Medium–High (USD tens to hundreds of thousands) | High shot life; suited for long runs & multi-cavity |

| Die casting die | High (USD tens to hundreds of thousands) | Requires service; vacuum options increase cost |

| Progressive stamping die | High (USD tens to hundreds of thousands) | Optimized for millions of parts/year |

Representative Tooling Projects

Multi‑cavity PEEK Connector Molda