Tooling & Mold Engineering

Injection Molds — Prototype & Production Tooling

Comprehensive injection mold services from quick-turn aluminum prototype tools to hardened steel production molds with hot runner, valve‑gate and multi‑cavity strategies. We engineer cooling, venting, gating and tool maintenance plans to deliver consistent parts at the expected quality and cost per piece.

- Prototype tools for validation and production molds engineered for long shot life

- Hot runner, valve gate, family molds, multi‑shot and insert/overmold tooling

- Tryout, FAI, process window documentation and lifecycle maintenance programs

Aluminum Prototype Molds — Quick Turn

Hardened Steel Production Molds — H13 / P20

Hot Runner & Valve Gate Systems

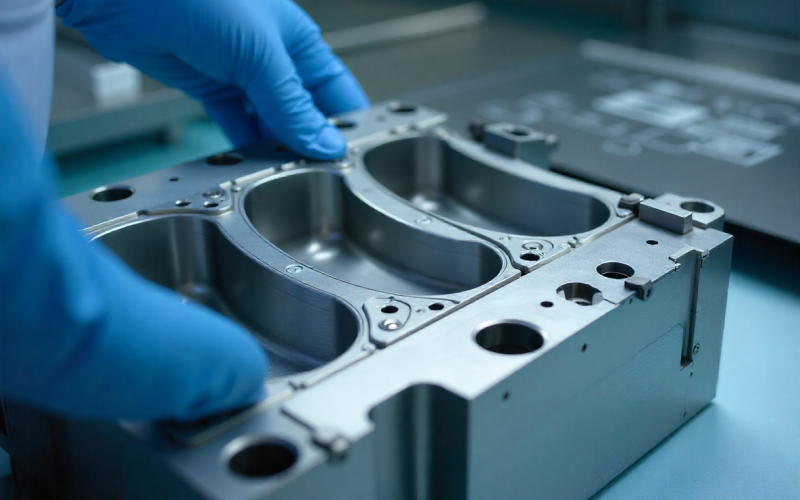

Production Molds — Hardened Steel & Long Life

Production molds are designed for durability, repeatability and cosmetic quality. We use tool steels like P20 for general use and H13 for high thermal cycling wear resistance. Molds incorporate hot runners, valve gates, family/multi‑cavity strategies and conformal cooling where beneficial.

Design considerations

Part gating and runner balance for uniform fill and reduced warp

Cooling channel design and conformal cooling (where AM is used) to lower cycle time and temperature gradient

Ejection strategy and slide/undercut mechanics to ensure reliable automation

Quality & capacity

High shot life molds with documented process windows. Support for multi‑cavity (4–16+ where feasible), automated loading/unloading, and integration to injection presses with data logging for SPC.

Prototype Molds — Fast Validation (Aluminum / Soft Tooling)

Prototype tooling is optimized for speed and low initial cost. Aluminum or soft steel molds allow rapid part samples for fit, form and function testing, early validation of cosmetic surfaces, and process development before committing to hardened production tooling.

When to use

- Early program verification: design validation, ergonomics and functional prototypes

- Low volume runs, pre-production pilot builds and market samples

- Testing of overmold and insert fits before large tooling investment

Hot Runner, Valve Gate & Runner Strategies

Hot runner systems reduce material waste and improve cycle time. Valve gates are used where precise gate pin control is required (zero vestige, family molds, cosmetic gates). We select runner strategies based on part geometry, polymer, and volume economics.

Benefits & selection

- Hot runner: lower scrap, faster cycles, balanced filling

- Valve gate: controlled shear, improved cosmetic gate finish, suitable for family molds

- Cold runner: low tool cost for low volumes or highly filled materials

Insert Molding, Overmolding & Multi‑Shot Tooling

We design molds to accept metal or plastic inserts, overmold soft grip features, and run multi‑shot operations in a single tool. Integrated insert stations and automated pick‑and‑place reduce assembly steps and improve reliability.

Capabilities

- Insert cavities with precise location bosses and retention features

- Two‑shot and multi‑material molds for integrated soft touch or seals

- Robotic part transfer or indexed mold platens for multi‑shot synchronization

Cooling, Venting & Material Considerations

Effective cooling and venting are crucial to cycle time, surface finish and dimensional stability. We simulate cooling networks and advise on vent placement for low knit lines and reduced burn marks. Material selection (glass fill, high temp polymers, PEEK/PEI) influences gating, venting and mold wear.

Conformal Cooling

Where geometry requires, AM conformal cooling reduces cycle time and shrink differential.

Venting

Micro vents, gas traps and bleed channels specified to avoid flashes and burn marks.

Polymers

Engineering resins (PA, PEEK, PPA), PC/ABS, TPU and filled grades — tooling designed to handle abrasives and high melt temps.

Surface Finish

Polish, texture, EDM finishes and coatings for release and wear resistance.

Tryout, First Article & Process Validation

Tool tryout includes sample runs, dimensional CMM, surface finish verification, cosmetic sample approval and process window documentation. We produce FAI packages, recommended SPC checkpoints and initial production samples for customer approval.

Deliverables

- FAI report and CMM data for critical datums

- Sample part gallery and photographic evidence of cosmetic zones

- Process window, cycle time, clamp force and cooling profiles

- Operator setup sheets and maintenance checklist

Tool Maintenance & Lifecycle Support

Planned preventative maintenance (PM), spare core/insert programs, EDM repair, recoating and emergency repair lanes protect production uptime. We document shot counts and recommend PM intervals tied to tool usage and part material abrasiveness.

Services include

- PM schedules, polish cycles and cooling channel maintenance

- EDM rework, insert replacement, recoating (TiN/TiCN) and re‑hardening

- Tool storage, corrosion protection and on‑site repair options

Representative Specs & Lead Times

| Tooling Item | Typical Lead Time | Notes |

|---|---|---|

| Aluminum prototype mold | 1–4 weeks | Quick samples, limited shot life |

| Hardened steel production mold (P20/H13) | 6–16+ weeks | Hardened, polished, coatings and heat treatments add time |

| Multi-cavity hot runner mold | 8–18 weeks | Balancing and hot runner commissioning required |

| Overmold / multi-shot tooling | 8–20 weeks | Complex synchronisation for multi-shot cycles |

| Conformal cooling (AM channels) | Add 2–6 weeks | Design and post-processing (heat treat) considerations |

Representative Tooling Projects

16‑Cavity Connector Mold (PEEK)

High‑temperature PEEK multi‑cavity mold with family gating and hot runner, integrated insert station for metal leads — reduced downstream assembly and achieved target cycle time.

Hardened Cosmetic Housing Mold

Two‑shot family mold with valve gates and polished cosmetic finish; supplied mold run kit and process window enabling immediate production release.

Frequently Asked Questions

How do I decide cavity count?

Cavity count is chosen by balancing per‑part cycle time reduction against increased tooling cost and complexity. We provide amortization and cycle time models to recommend an optimal cavity count for your volume.

When is conformal cooling worth the cost?

Conformal cooling is recommended when cycle time, temperature differential or part warp are constrained and when AM channel benefits outweigh added tool cost and lead time. We run simulations to quantify ROI.

Can you design molds for abrasive-filled materials?

Yes — we specify abrasion‑resistant steels, surface coatings and recommended runner designs to minimize wear from glass‑filled and mineral‑filled polymers.

What warranty/support comes with molds?

We provide tooling acceptance documentation, a limited warranty for manufacturing defects, and optional SLA packages for maintenance, spares and emergency repair support. Terms are defined per contract.

Start Your Injection Mold Project

Upload your part CAD, expected volumes, material choice and cosmetic requirements. We’ll deliver a tooling recommendation, estimated lead time and cost amortization model — typically within 24 business hours.