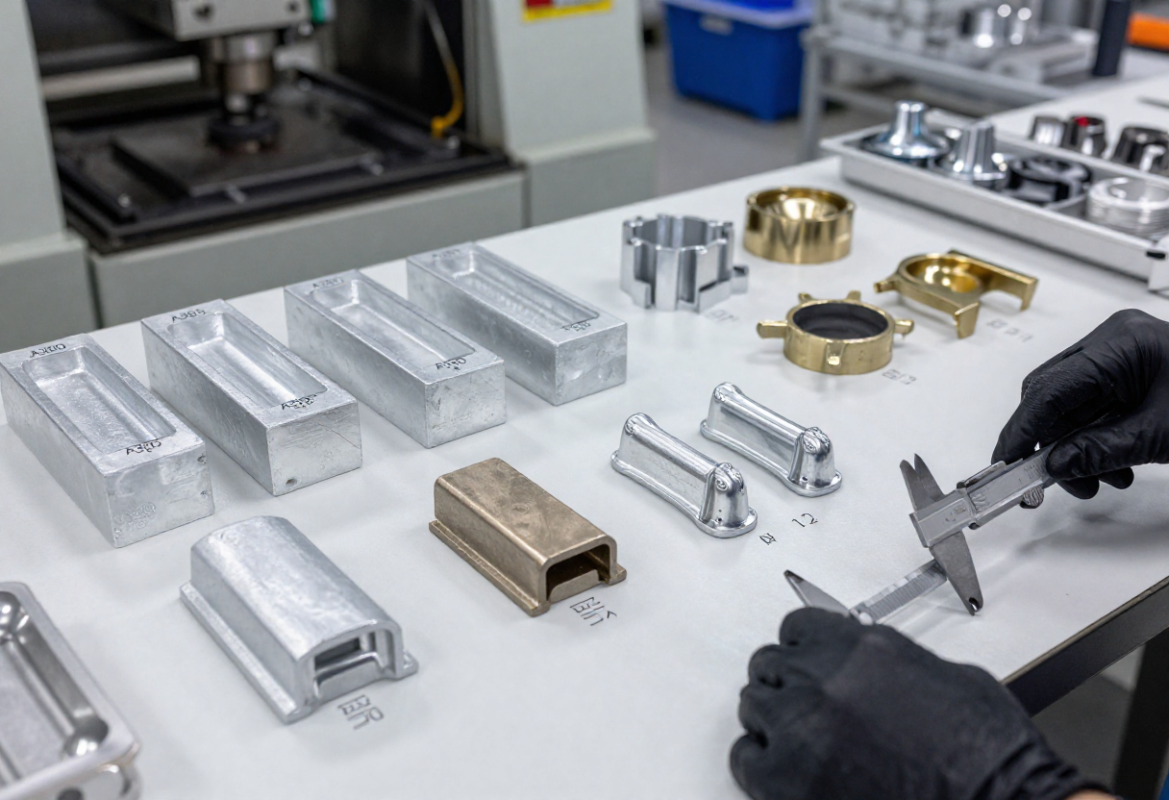

Tooling & Mold Engineering

Die Casting Molds (Aluminum & Zinc) Cold‑Chamber & Hot‑Chamber Tooling

We design and build die casting dies for aluminum (cold‑chamber) and zinc (hot‑chamber) parts, with options for vacuum/low‑pressure fill, controlled cooling, ejector strategies and integrated CNC finishing. Our tooling reduces porosity, improves mechanical integrity and supports production ramp‑up with maintenance & spare strategies.

- Cold‑chamber dies for aluminum alloys; hot‑chamber dies for zinc alloys

- Vacuum/low‑pressure die options to reduce porosity for pressure‑bearing parts

- Tryout, de‑burr/CNC machining integration and lifecycle maintenance

Aluminum Dies Cold‑Chamber

Vacuum & Low‑Pressure Options

CNC Finishing & Machining`

Alloy Selection & Application Guidance

We commonly support aluminum alloys (ADC12, A380, A356) and zinc alloys (Zamak family). Selection is driven by structural needs, thermal conductivity, surface finish and plating requirements. Aluminum is preferred for lightweight structural housings and thermal parts; zinc for fine detail and plated cosmetic components.

Considerations

- Aluminum: higher strength, better thermal properties, requires cold‑chamber process

- Zinc: excellent detail, low melting point, hot‑chamber suitable and great for plating

- Corrosion & coating: choose alloys compatible with intended surface treatments (anodize for aluminum; nickel/chrome plating for zinc)

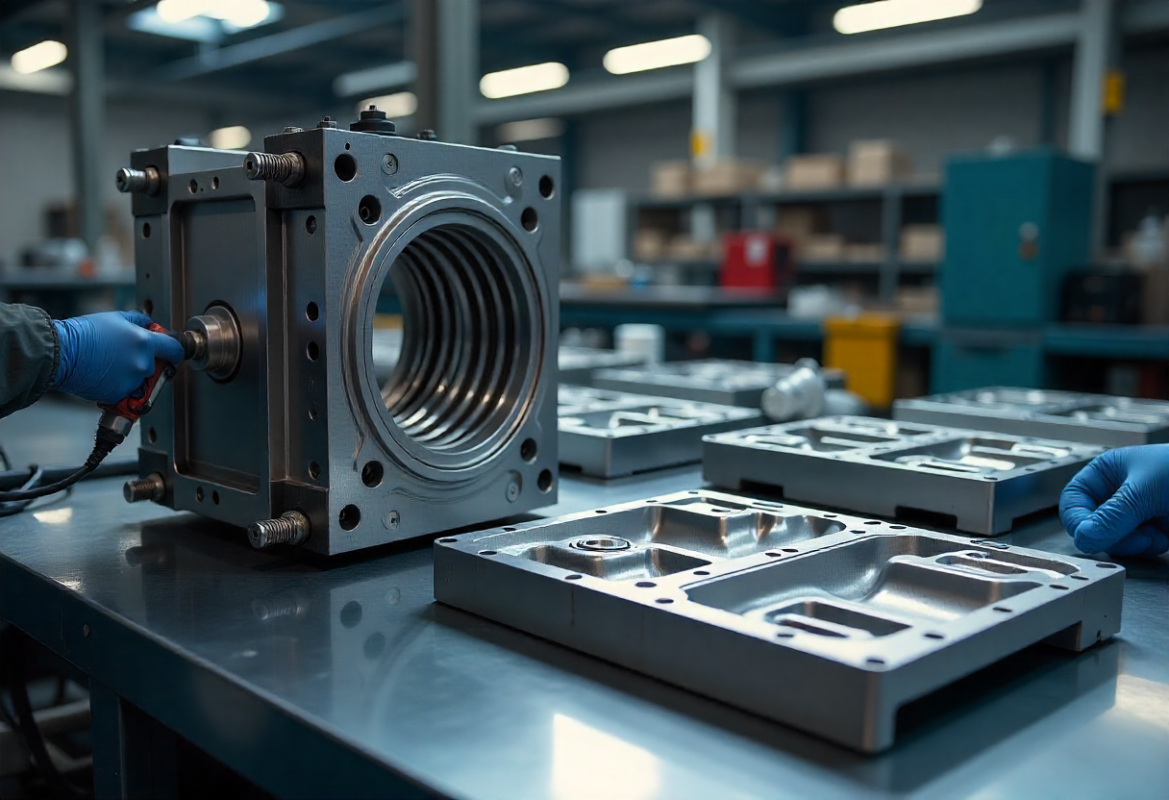

Vacuum & Low‑Pressure Die Casting

Vacuum-assisted and low‑pressure die casting minimize entrapped air and reduce shrink porosity. These techniques are used for pressure‑bearing housings, fluid passages and parts requiring leak‑tight seals or high fatigue life.

Benefits

- Improved internal integrity and reduced porosity

- Improved mechanical properties and pressure sealing

- Better downstream machining outcomes (fewer porosity interruptions)

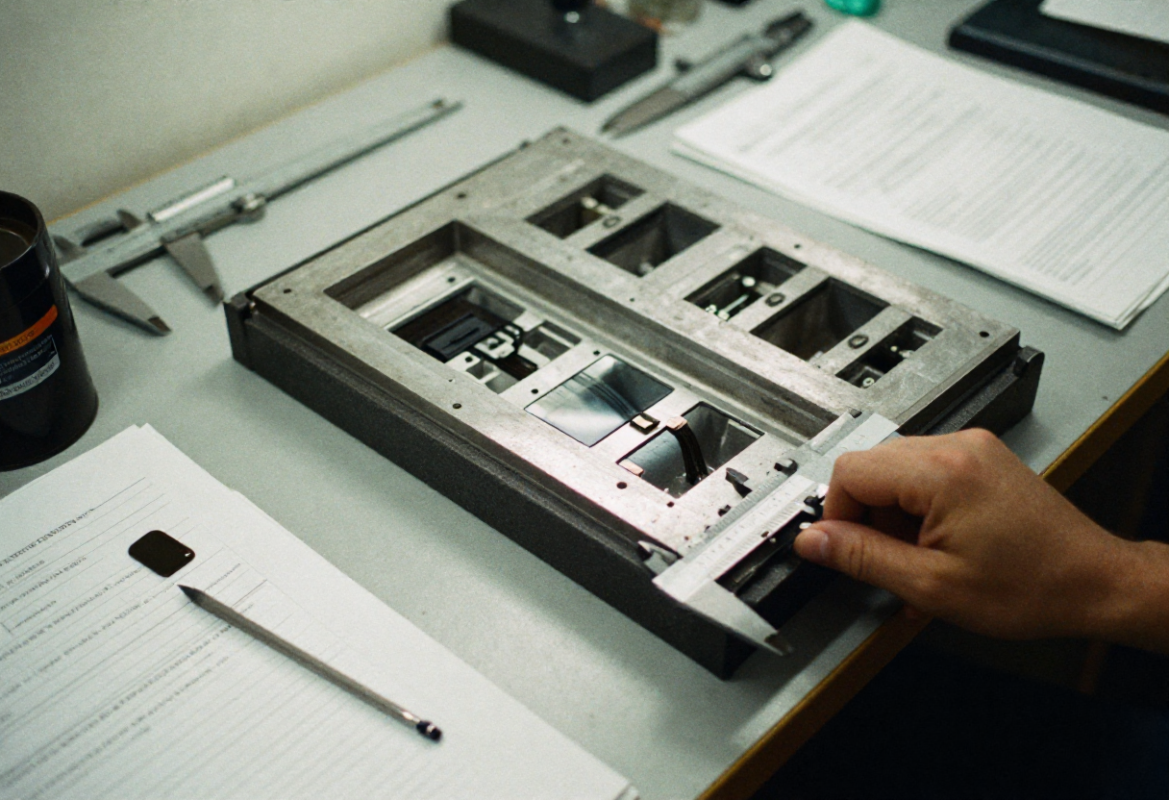

Die Design Gating, Cooling & Ejection

Die design balances fill speed, solidification and cooling to control shrink and porosity. We design gating for directional feed, optimize cooling circuits to control cycle and thermal gradients, and engineer ejector and slide systems for reliable part release and minimal rework.

Gating & Riser Strategy

Gates positioned for smooth fill and directional solidification. Risers and feeders sized to avoid shrink porosity in critical sections.

Cooling & Thermal Control

Optimized cooling channels to manage solidification, reduce cycle time and prevent hot spots. Die temperature control critical for consistent microstructure and porosity outcomes.

Tryout, CNC Finishing & Post‑Process Integration

Die tryout verifies fill, venting, venting, and part ejection. After initial casting runs, we provide CNC finishing fixtures for sealing faces, screw bosses and optical surfaces. Our workflow includes deburring plans, shot sampling, and integration of finishing tolerances into the tool acceptance criteria.

Deliverables

- Tryout report, sample parts and porosity analysis

- CNC machining fixtures & first article machined parts

- Process window and recommended inspection checkpoints

Tool Maintenance, Spares & Rapid Repair

Planned preventative maintenance (PM), spare inserts and emergency repair lanes reduce downtime. Repairs include EDM, insert replacement, resurfacing and re‑hardening. We offer tooling storage, periodic inspections and SLA options for prioritized repair turnaround.

Spare strategy

Identify critical wear components (slides, cavities, inserts) and maintain spares to enable quick swap and continued production while repairs occur.

Representative Specifications & Lead Times

| Tool Type | Typical Lead Time | Notes |

|---|---|---|

| Cold-chamber aluminum die (production) | 10–20 weeks | Complex dies, vacuum assists and CNC finish increase lead time |

| Hot-chamber zinc die | 8–16 weeks | Faster cycles but careful gating and venting required for detail |

| Vacuum/low-pressure variants | Add 2–6 weeks | Additional verification & commissioning required |

| CNC finishing & fixtures | 1–6 weeks | Depends on number of machined faces and tolerances |

Representative Projects

Vacuum Aluminum Housing Die

Low‑porosity housing die with vacuum assist, post‑machined sealing faces and integrated cooling—passed leak and fatigue tests for automotive power module.

High‑Detail Zinc Cosmetic Die

Hot‑chamber zinc die optimized for plating, produced parts with excellent surface finish and tight detail for consumer hardware trims.

Frequently Asked Questions

When should I choose vacuum die casting?

Specify vacuum casting when internal porosity affects pressure containment, fatigue life or leak paths. We’ll evaluate part function and recommend vacuum or low‑pressure approaches if needed.

How do you control shrink and distortion?

We use gating/riser strategies, optimized cooling, controlled fill and directional solidification designs to control shrink. Post‑cast machining is used for critical sealing and datums.

Can you support plating and anodize requirements?

Yes — we design die finishes and alloy choices to support downstream plating and painting processes. Zinc parts typically receive nickel/chrome plating; aluminum parts are machined then anodized or coated.

What inspection and NDT options exist for cast parts?

We support visual, dimensional CMM, X‑ray/CT for porosity detection, ultrasonic and pressure testing for housings. NDT scope is defined per part criticality and regulatory needs.

Start Your Die Casting Project

Upload your part CAD, target volumes and functional requirements. We’ll return a die recommendation, estimated lead times, porosity mitigation plan and amortization analysis — typically within 24 business hours.