Cold Plate FSW & Laser Welding Fixtures — Precision Fixturing for Thermal Assemblies

We design and manufacture fixturing and tooling for friction stir welding (FSW) and laser welding of cold plates and thermal assemblies used in power electronics, EV inverters and high‑power modules. Our fixtures control part registration, clamping, thermal sinks, reaction forces and sensor feedback for repeatable, high‑quality welds.

- FSW fixtures: torque reaction, robust backing, sacrificial supports and Z‑axis control

- Laser welding fixtures: precise datum registration, beam access, gas shrouding and active cooling

- Robotic/automation interfaces, quick‑change pallets, sensors and traceable process records

FSW Fixtures — Torque Reaction & Backing

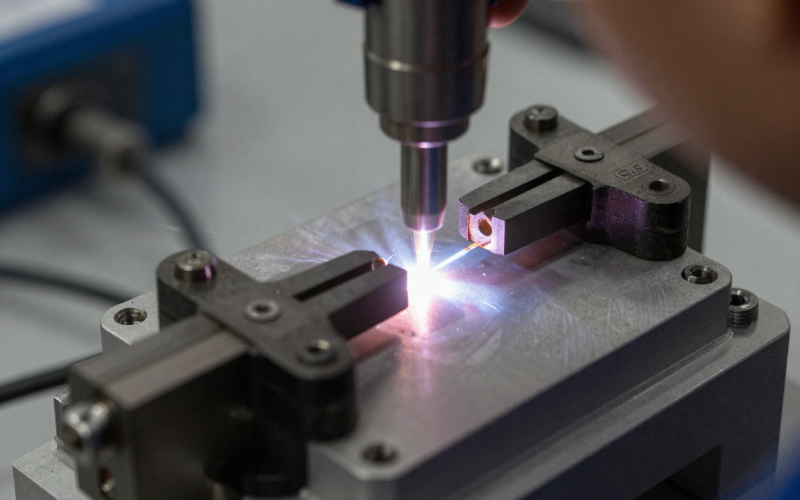

Laser Welding Fixtures — Beam Access & Gas Shroud

Robotic Cells & Quick‑Change Pallets

Friction Stir Welding (FSW) Fixtures

Critical fixture elements

Rigid datum locators and preload clamps to maintain joint gap and surface flatness. Sacrificial backing plates or hardened inserts to protect fixture from tool wear. Z‑axis control with high‑accuracy encoders and force sensors for plunge depth and spindle load feedback. Integrated coolant channels or thermal mass to control heat build‑up near the tool

Process & QC integration

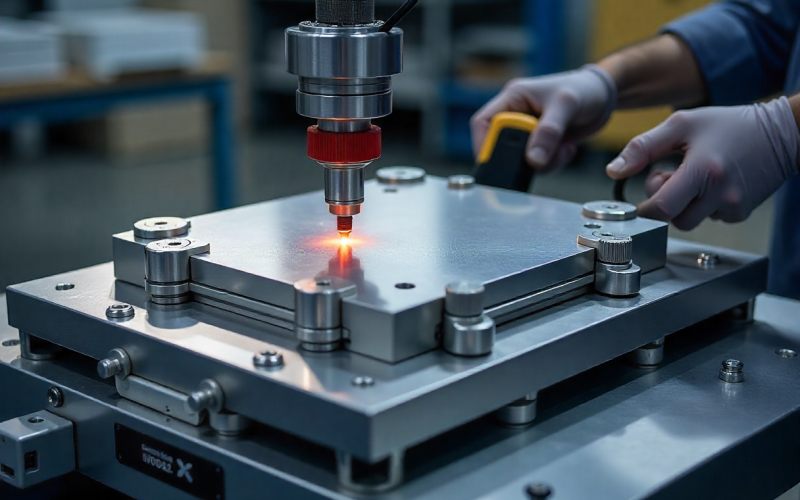

Laser Welding Fixtures

Key design points

- Precision locators and fine‑adjustment micro‑clamps to control gap & alignment

- Beam access windows, mirror/nozzle clearance and fiber‑optic routing provisions

- Shielding gas manifold integration with adjustable flow to control oxide and porosity

- Active cooling (water channels or thermal plates) to extract heat from weld zones

Thermal Management & Distortion Control

Methods

- Active water cooling channels in fixture plates and contact pads

- Thermal spreader plates to distribute heat across a larger mass

- Staged weld patterns and dwell times to minimize asymmetric heating

- Pre‑heat or post‑heat as part of process where metallurgical needs dictate

Clamping, Registration & Quick‑Change Pallets

Options

- Hydraulic or pneumatic clamps with force feedback

- Mechanical cam clamps for quick engage/disengage in automated cells

- Precision dowel and tapered pin datums for pallet repeatability

- Custom soft‑contact pads where surface protection is required

Fixture Materials & Construction

Hardened tool steel

Wear resistant contact surfaces and clamping faces

Copper alloys

High thermal conductivity for heat extraction

Aluminum tooling bodies

Lightweight pallet structures with machined datum features

Ceramic / composite pads

Where electrical isolation or thermal barrier needed

Sensor Integration & Process Feedback

Typical sensors

- Axial force and torque sensors (FSW spindle feedback)

- Thermocouples and IR pyrometers for weld zone temperature

- Laser seam trackers and seam finders

- Contactless displacement sensors for gap monitoring

Robotic Integration & Safety

Integration deliverables

- Pallet and interface drawings for robotic grippers

- Cycle timing analysis and takt optimization

- Safety interlocks, light curtains and E‑stop integration

Tryout, Qualification & Quality Gates

Tryout deliverables

- First article weld assemblies with dimensional reports

- Weld energy/force vs quality mapping and recommended process window

- Sensor calibration records and control charts

- Fixture acceptance checklist and maintenance schedule

Maintenance, Spares & Lifecycle Support

| Item | Typical Range / Value | Notes |

|---|---|---|

| Fixture flatness | ≤ 0.05 mm across critical datum | Depends on weld seam length and optical requirements |

| Datum repeatability (pallet) | ≤ 0.02–0.05 mm | Important for laser seam accuracy |

| Clamp force | Programmable 0—50 kN | Hydraulic/pneumatic options with feedback |

| Cooling capacity | Up to 5 kW+ localized | Based on weld energy and cycle time |

Representative Projects

FSW Fixture for EV Inverter Cold Plate