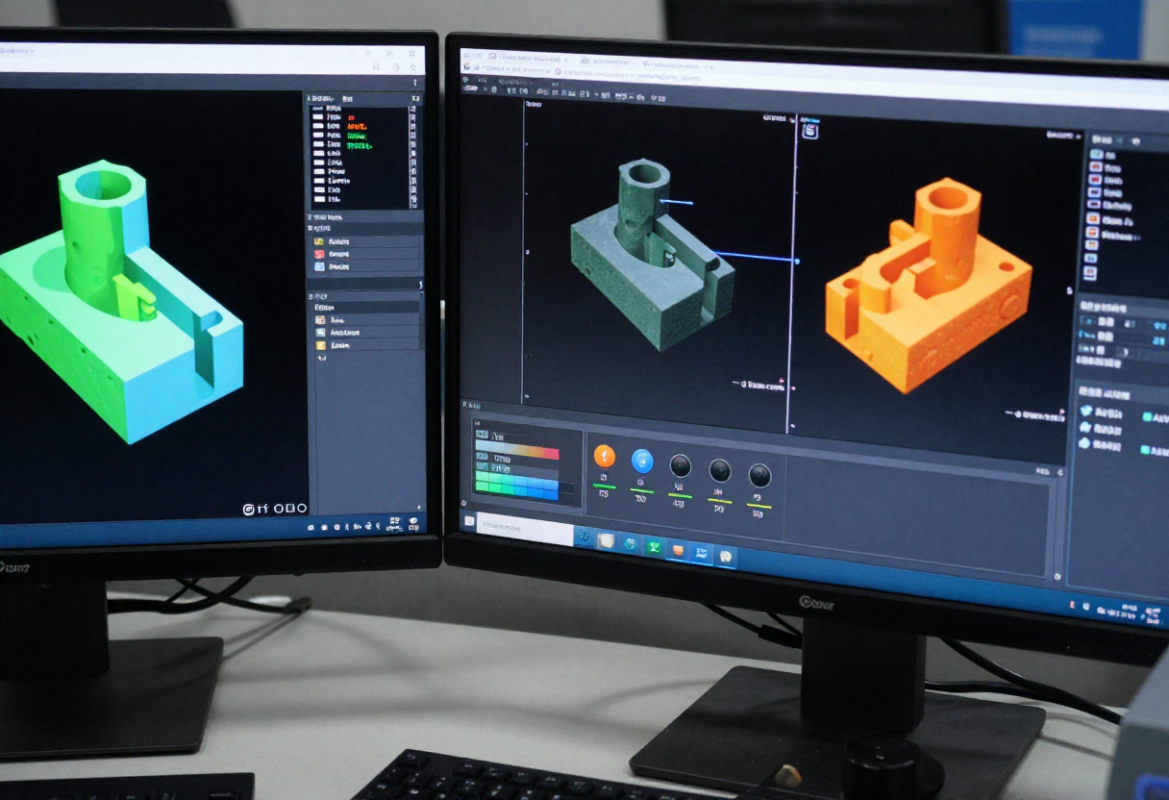

Tooling & Mold Engineering

Casting Molds & Patterns Sand, Gravity & Investment Casting

Complete pattern and mold engineering for sand, gravity and investment (lost‑wax) casting processes. We design gating/riser systems, produce patterns (wood, epoxy, 3D printed), run trials, integrate CNC finishing and provide NDT & lifecycle support from prototypes to production volumes.

- Pattern making: wood, epoxy, urethane, and 3D printed masters for investment wax

- Gating, riser & solidification simulation to minimize porosity and improve yield

- Tryouts, CT/X‑ray NDT, CNC finishing fixtures and heat treatment integration

Investment Casting — High Detail & Thin Walls

Sand Casting — Large & Flexible Tooling

Gravity Casting — Moderate Complexity & Low Turbulence

Overview

Casting tooling converts part geometry to a mold system that controls metal flow, solidification and trapped gas. Early DFM and solidification planning reduce porosity and rework. We partner with foundries and CNC shops to provide a seamless chain: pattern → mold → pour → finishing → test.

Investment (Lost‑Wax) Casting Tooling

Investment casting yields high‑detail, thin‑wall parts with excellent surface finish and tight tolerances. We produce master patterns for wax tooling, design gating systems for shell molding and control burnout cycles and melt chemistry to meet microstructure and tolerance targets.

When to use

- Complex geometry, thin walls, fine detail and tight tolerances

- Aerospace, medical, precision pump components and small turbine parts

- Parts where minimal machining and excellent surface finish reduce total cost

Sand Casting Tooling

Sand casting is flexible for large parts and iterations with lower upfront tooling cost. We provide pattern masters (wood, epoxy or 3D print), coreboxes, gating & riser design and sand formulation recommendations to balance surface finish, dimensional control and cost.

Advantages

- Low cost tooling for large, heavy sections

- Rapid changes to pattern for design iteration

- Suitable for ductile iron, cast iron, steel and large aluminum sections

Gravity & Low‑Pressure Casting

Gravity and low‑pressure casting offer improved fill control vs high‑pressure casting, reducing turbulence and entrapped air — useful for moderate complexity parts requiring better mechanical properties and lower porosity than typical high‑pressure processes.

Use cases

- Large structural aluminum housings and moderate‑detail components

- Reduced turbulence fills for better microstructure and fewer defects

Pattern & Corebox Engineering

Pattern choice depends on process: wax masters for investment, wood/epoxy/3D printed patterns for sand masters, and CNC fixtures for gravity patterns. We design coreboxes for internal features, gating/riser plugs and provide pattern revision control for lifecycle management.

]Pattern options

- 3D printed masters for rapid iteration (investment wax tooling)

- Epoxy or wood patterns for sand tooling

- Aluminum or steel patterns for high repeatability and long life

Solidification Simulation & Metallurgy

We run gating/riser and solidification simulation (casting analysis) to predict shrink behavior and porosity and to optimize gating positions. Metallurgical guidance includes melt chemistry control, inoculation, degassing and heat treatment workflows to meet mechanical property targets.

Deliverables

Casting simulation reports, recommended melt recipes, heat treatment schedules and metallurgical acceptance criteria.

Inspection & NDT

We support visual inspection, dimensional CMM, dye penetrant, ultrasonic, X‑ray/CT scanning for internal porosity and pressure/leak testing for housings. NDT scope is tailored to part criticality and regulatory needs.

Typical NDT options

- X‑ray / CT for porosity mapping

- Ultrasonic thickness & flaw detection

- Dye penetrant and visual inspection for surface defects

Tooling Lifecycle & Maintenance

Pattern preservation, spare cores, and controlled storage protect pattern life. For investment tooling we manage wax tool sets and shell mandrel records. For sand patterns we manage pattern repair and refitting. We supply refurbishment and rework services and maintain tooling records for version control.

| Item | Typical Lead Time | Notes |

|---|---|---|

| Investment wax tooling (pattern set) | 3–8 weeks | Depends on complexity and shell cycles |

| Sand pattern & corebox | 2–6 weeks | Rapid iteration; material dependent |

| Gravity casting pattern | 3–8 weeks | Pattern finish and machining add time |

| Tryout & first article | 1–4 weeks after tooling ready | Includes sample pour and inspection |

Representative Projects

Investment Cast Turbine Component

High‑precision alloy investment casting with tight tolerances, vacuum burnout profile and post‑machining to aerodynamic finish; supplied metallurgical certification and CT scan report.

Sand‑Cast Pump Housing

Large ductile iron sand casting with pattern iteration to control shrink and core location; CNC machined sealing faces and ultrasonic inspected for porosity.

Frequently Asked Questions

How do you decide investment vs sand casting?

Investment for fine detail, thin walls and minimal machining; sand for large sections and flexible low‑cost tooling. We assess geometry, volumes and finishing needs to recommend the best process.

Can you control porosity in castings?

Yes — we use gating/riser optimization, vacuum/low‑pressure fills, melt degassing and directional solidification strategies. NDT like CT/X‑ray verifies internal integrity.

What documentation is provided with production runs?

FAI/PPAP packages, material certificates (MTR), CMM reports, NDT reports, heat‑treat records and traceability to pattern versions are provided as required.

Start Your Casting Tooling Project

Upload your part CAD, target volumes, and functional requirements. We’ll return a recommended casting process, tooling plan, lead time and porosity mitigation strategy — typically within 24 business hours.