US Dallas Warehouse Support

📦 Local Stock & Distribution 🔄 Returns / Repair Lane

📊 VMI / JIT ⏱️ Reduced Lead Time vs Intl Shipments

Faster delivery, lower damage, simplified returns

Regional Fulfillment & Post‑Sale Services

Receiving & Inspection

Inbound inspection, lot verification, material traceability and quarantine workflows to ensure only conforming goods enter inventory.

Kitting, Light Assembly & Customization

Build-to-order kitting, light mechanical assembly, labeling and personalization prior to shipment to reduce field installation work.

Returns, Repair & Refurb

RMA handling, repair coordination, send‑back logistic support and refurbishment workflows with disposition tracking.

VMI & Inventory Management

Fill Rate

Target > 99% for VMI SKUs

Inventory Accuracy

Target > 99.5% after cycle count

On‑time Ship

Target > 98% DDP

Damage Rate

Target < 0.5% after packaging optimization

`

Dallas Warehouse Services

| Service | What We Do |

|---|---|

| Receiving & Inspection | Count, inspect, lot trace, quarantine and inbound reporting; photo evidence for high‑value items. |

| Kitting & Assembly | Pick & pack kitting, BOM validation, light torque, cable routing and final QC. |

| Order Fulfillment | Parcel, LTL and LCL outbound, export docs, DDP handling and carrier integrations. |

| Returns & Repair | RMA intake, triage, repair coordination, refurbishment and dispositioning with root cause logging. |

| VMI & Consignment | Stock ownership models, reorder automation, replenishment and periodic reconciliation. |

| Custom Packaging & Kitting | On‑demand packing, polybagging, foam inserts and custom labels to support channel requirements. |

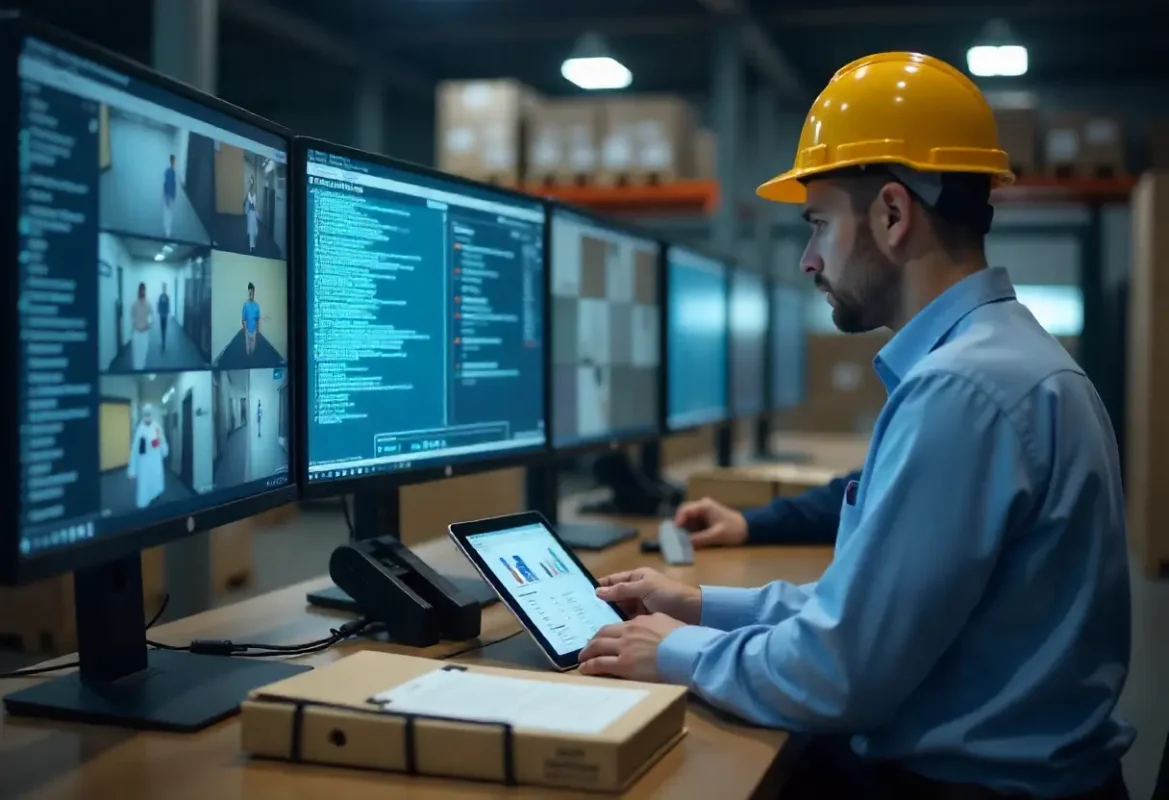

How We Integrate With Your Systems

Warehouse SLA Options

Options available: same‑day pick, next‑day fulfillment, two‑day regional service. SLA tiers include picking accuracy SLAs, lead time windows and chargeback terms for exceptions.

Security & Compliance

Receiving & Inspection Workflow

| Step | Description |

|---|---|

| ASN & Pre-advise | Advance ship notices are validated against expected shipments; discrepancies flagged before dock arrival. |

| Physical Count | Case/open piece counts and condition check with photo capture for exceptions. |

| Functional Check / QC | Random or 100% QC on CTQs with bench tests where required. |

| Putaway & Storage | Bin assignment, FIFO/LIFO rules, and special handling for sensitive items. |

| Inventory Reconciliation | Cycle counts and periodic audits with variance investigation and supplier claims initiation. |

Kitting, Light Assembly & Fulfillment

Capabilities

Multi-SKU kits, pick-to-carton, batch labeling, rework lanes and ESD-safe stations for sensitive electronics.

Returns, Repair & Refurbishment

Typical Flow

RMA creation → inbound inspection → triage (repair / refurb / scrap) → repair/replace → final QC → return to stock or ship to customer.

VMI & Inventory Management

Fill Rate

Target > 99% for VMI SKUs

Inventory Accuracy

Target > 99.5% after cycle count

On‑time Ship

Target > 98% DDP

Damage Rate

Target < 0.5% after packaging optimization

`

Pricing Models & SLA Options

| Model | When to Use |

|---|---|

| Storage + Pick Fees | Low complexity SKUs and predictable throughput |

| All‑in Kitting Package | High complexity kits where predictability is preferred |

| VMI/Consignment | Programs aiming to reduce buyer working capital |

Dallas Warehouse Setup Checklist

| Item | Purpose |

|---|---|

| Forecast & SKU list | Determine space and throughput needs |

| Packing & kitting specs | Define BOM, instructions and materials |

| Integration method | Choose EDI/API/Portal and map data fields |

| SLA & KPIs | Agree SLAs, chargebacks and reporting cadence |

| Returns policy | Define RMA flow, repair vs replace criteria |