Xometry offers precision tube bending services for round metal tube stock to meet your needs.

STEP | STP | SLDPRT | IPT | X_T | X_B | CATPART | PRT | SAT | JT files

All uploads are secure and confidential.

Xometry’s Instant Quoting Engine is covered by U.S. Pat. Nos. 11,086,292, 11,347,201, 11,693,388, 11,698,623, 12,099,341, and 12,189,361. Other patents pending.

Tube bending consists of a series of manufacturing processes that alter the shape of a pipe or tube to create the desired geometry or features that meet specific requirements. In the process, tube stock is loaded into a bending machine which uses mechanical forces to push the tube against dies and rollers that cause the tube to conform to a shape. Tubes can be bent two-dimensionally where the openings remain on the same plane or in three dimensions where they sit on different planes. Multiple bends are allowed in CNC tube bending, reducing the need to weld or fabricate a complex shape with elbow and straight tube sections.

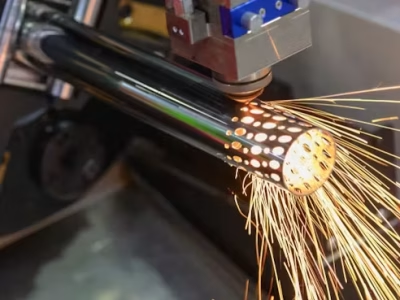

Xometry offers a full suite of custom tube bending services for your application with instant online quoting, DFM, and competitive lead times. Whether you are looking for standard rotary draw tube bending or highly precise mandrel tube bending, Xometry offers different processes to meet your requirements for tube fabrication services in both low and high volumes. Xometry also offers laser tube cutting services for parts that include cut features such as holes, slots, and more. Material choices for our tube bending services include stainless steel, aluminum, and alloy steel.

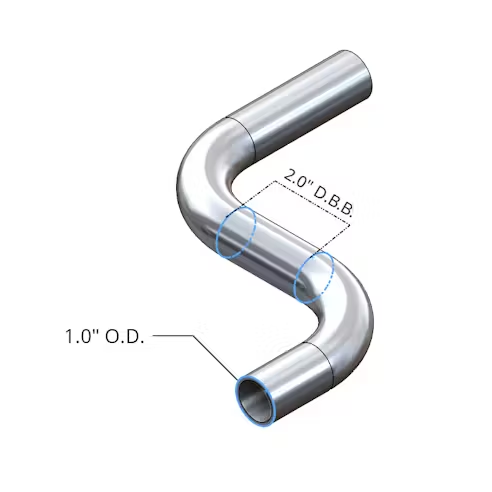

Our tube bending service is built around typical industry standards to ensure a smooth manufacturing experience. Xometry can achieve tighter tolerances after a manual review by one of our project engineers. In the list below, you’ll find the standards and tolerances specific to our drawn or mandrel bending techniques for round profiles:

View more standards on our manufacturing standards page.

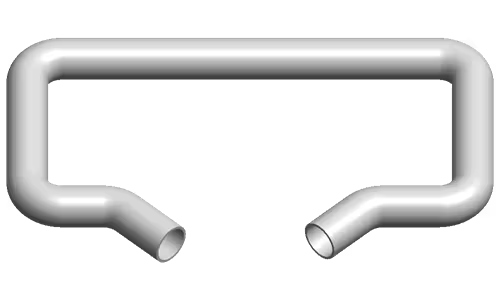

Xometry’s tube bending services are for creating custom round tubes in a variety of shapes and materials:

The table below depicts the range of tube sizes available for these services. Learn more on our standard tube sizes resource page.

| Material | Minimum O.D. | Maximum O.D. | Minimum wall thickness | Maximum wall thickness |

|---|---|---|---|---|

| Stainless Steel 304 | .250" | 2.000" | .035" | .188" |

| Stainless Steel 316 | .250" | 2.000" | .035" | .120" |

| Aluminum 6061 | .250" | 2.000" | .035" | .188" |

| Steel 4130 (Chromoly) | .375" | 2.000" | .035" | .188" |

| Steel A513 Type 5, DOM | .250" | 2.000" | .035" | .188" |

| Steel A513 Type 1, HREW | 1.000" | 2.000" | .065" | .120" |

| Steel A513 Type 2, CREW | .500" | 2.000" | .035" | .065" |

See additional details on our standard tube sizes page.

When it comes to tube bending, there are a few things you can do when designing your parts to ensure a smoother quoting and manufacturing experience. We’ve compiled a few tube bending design for manufacturing (DFM) tips below. For additional tips, check out our top tube bending design tips article.

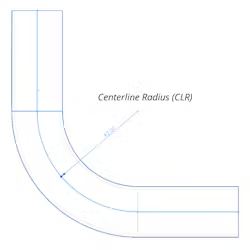

Beyond the bend distance guidelines, Xometry has found the following tube diameter (OD) to center line radius (CLR) combinations more readily available across a broad network.

The list below shows a tube OD in decimals or fractions as the related CLR to help you design your project. It is recommended that single tubes contain only one CLR for ease of manufacturability.

OD to CLR Recommended Combinations:

(Above: Center Line Radius, CLR)

Xometry offers a full range of tube bending capabilities and pipe bending services. These services include:

Mandrel Tube Bending – This method (also known as mandrel bending) is similar to rotary draw bending; however, it fully retains the internal tube profile throughout the bend. This process is accomplished using internal support known as a mandrel that preserves the structure of the tube during bending, ensuring that little to no unwanted deformation occurs. The mandrel tube bender has a long bed with a mandrel rod, which holds the mandrel right at the tangent point of the bend. The tube slides over the mandrel, the machine clamps down on it, and the tube is bent while the mandrel remains stationary. Mandrel tube bending is especially useful for thin wall thicknesses, large diameters, and tight radii, where collapsing during bending is common.

Rotary Draw Tube Bending – by far the most popular method, rotary draw benders use a clamping die, radius (or bend) die, and pressure die to hold the tube to form during the entire bending process. The tube is clamped to the bend die and is “drawn” around the other dies via hydraulic or electrical power, resulting in a highly accurate and repeatable bend. Rotary draw tube bending processes can be manual, semi-manual, or CNC-operated. Computer-guided rotary draw bending allows unmatched precision (especially for high-volume applications). However, setup time can be longer, and each unique bend requires tooling to be created.

Roll Tube Bending – In roll tube bending (also known as roll bending), three dies (or rollers) are used to lock down the tube, where a piston presses down on the tube, and the operator “rolls” the pipe through the machine, causing a gradual bend (also known as an arc). The tube is reset into the dies, the piston is lowered further, and the process is repeated until the desired profile is achieved. This method is often a manually-powered process; however, it can also be motorized for additional power input. Roll tube bending offers variable bends and angles without additional tooling and is ideal for large, gradual bends, but its accuracy and repeatability are limited.

Compression Bending – With compression bending, the tube or pipe is clamped in place, and force is directly applied, which creates the bend. This process is primarily utilized for single bend applications. No internal support is used with compression bending, which typically produces an oval cross-section and may result in crushing of the bend. Bends generally are limited to angles of 120 degrees or less.

Tube bending can be utilized across a diverse set of industries. From architectural and lighting fixtures in buildings to vehicle exhaust systems. Below is a list of just some of the notable sectors our tube fabrication and bending services are an ideal fit for:

Access hundreds of service suppliers through our easy-to-use platform.

We are ISO 9001:2015, ISO 13485, and AS9100D certified. Only the top shops that apply to become network suppliers make it through our qualification process.

Our team of Application Engineers and Process Specialists are available to support you and provide answers to all of your fabrication and manufacturability questions.

All uploads are secure and confidential