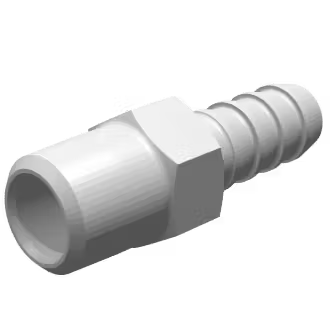

Get quotes in as fast as 2 hours and domestically made parts in as little as 5 business days through Xometry’s lightning-fast plastic injection molding service.

STEP | STP | SLDPRT | IPT | PRT | SAT files

All uploads are secure and confidential.

Xometry’s Instant Quoting Engine is covered by U.S. Pat. Nos. 11,086,292, 11,347,201, 11,693,388, 11,698,623, 12,099,341, and 12,189,361. Other patents pending.

Xometry offers an array of injection molding solutions, such as Prototype Molding and Production Molding, to meet your needs no matter your development stage. Thanks to Xometry’s vast manufacturing network, we can deliver injection molded parts faster than ever. With quick turn injection molding, a domestic molding service, we can achieve lead times as low as five business days!

This service is ideal for molding projects that require parts to be expedited and delivered as quickly as possible. With Xometry’s quick turn injection molding, you can take advantage of benefits such as:

With our quick turn molding service, our goal is to ensure we achieve the best possible turnaround times with as few limitations as possible. That said, there are some considerations when choosing this service to ensure it is suitable for your project. The table below shows our quick turn service offerings and order criteria. For projects requiring fewer limitations and greater customization, visit our plastic injection molding page to see our extensive molding services.

| Guidance | Quick Turn Molding |

|---|---|

| Tooling | Prototype grade aluminum molds |

| Mold Shot Life | Up to 2,500 shots |

| Size Limitations | Max XYZ of 10"x12"x3.9" |

| Mold Finishes | 6 Standard finishes (SPI-A2, A3, B2, B3, light or heavy textured) |

| Material Selection | Limited to 25 families of materials, or customer supplied |

| Inspection Options | Standard XYZ Dimension Report |

| Typical Quote Response Time * | Same day, in as little as 2 hours |

| Part Lead Times | Fast as 5 business days |

| Country of Origin | Domestic only (made in USA) |

* Quoting response times reflect requests received during business hours, requests received outside business hours will be addressed the following business day.

| Material Families Available |

|---|

| ABS | Acrylonitrile Butadiene Styrene |

| PC-ABS | Polycarbonate-Acrylonitrile Butadiene Styrene |

| ASA | Acrylonitrile Styrene Acrylate |

| HDPE | High-Density Polyethylene |

| HIPS | High-Impact Polystyrene |

| LCP | Liquid Crystal Polymer |

| LDPE | Low-Density Polyethylene |

| PA 6/6 | Polyamide 6/6, Nylon 6/6 |

| PBT | Polybutylene Terephthalate, Valox |

| PBT-PET | Polybutylene Terephthalate-Polyethylene Terephthalate |

| PC | Polycarbonate |

| PC-PBT | Polycarbonate-Polybutylene Terephthalate, Xenoy |

| PEBA | Polyether Block Amide |

| PET | Polyethylene Terephthalate, Rynite |

| PETG | Polyethylene Terephthalate Glycol, Eastar |

| PMMA | Polymethyl Methacrylate, Acrylic |

| POM | Acetal Polyoxymethylene, Delrin |

| PP | Polypropylene |

| PPA | Polyphthalamide , Zytel HTN |

| PS-PPE | Polystyrene-Polyphenyl Ethers, Noryl |

| PS | Polystyrene |

| Soft PVC | Polyvinyl Chloride, Geon HC |

| TPE | Thermoplastic Elastomer, Santoprene |

| TPU | Thermoplastic Polyurethane (Shore A) |

| TPV | Thermoplastics Elastomer, Vulcanized Rubber |

For more information on these materials, see our materials page. Customers may also supply their own materials upon request.

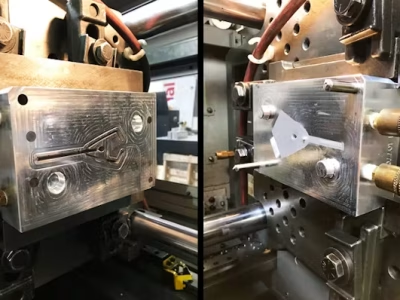

Xometry’s quick turn molding process involves using a proprietary insert and base system to produce molded parts rapidly. Depending on your project’s requirements and complexity, parts can be delivered as quickly as 5 business days!

Yes! As part of Xometry’s service, we offer DFM feedback on all projects both pre-sale as well as during final tool kickoff to ensure the project is a success.

After receiving the order, one of our manufacturing engineers reviews the statement of work. A case manager is assigned, and an appropriate manufacturing supplier is identified. A comprehensive DFM/PEG report is created and provided for approval. Upon approval, tooling and mold production is commenced. T1 samples are produced and shipped for approval. Upon approval, the remaining parts are made.

Quick turn molding is available for order quantities of 50 and greater. We offer urethane casting and 3D printing services, which are great options for lower-quantity orders.

Injection molding is used across various industries, including aerospace, medical devices, consumer goods, energy, electronics, automotive, robotics, toys, and more.

3D printing is an excellent process for rapid prototyping! However, prototyping with injection molding enables a much more comprehensive range of materials, finishes, and textures that other processes do not offer. Prototyping with injection molding also paves the way for potential full-scale production in the future. You can iterate and tune the design to fit the same process used for production quantities. Many customers do initial prototyping using 3D printing but later move onto injection molding when preparing to scale production and bring their creation to its final vision.

A MUD (Master Unit Die) is a type of mold that uses a standard injection molding frame that utilizes inserts that define the shape of the internal cavity and thus the eventual part. Think of it as a quick-change system akin to swapping out the head of a disposable razor. Ultimately this type of tool helps drive lower-cost and lead time as most of the machining time will be focused on the core and cavity work, rather than all other aspects of a more complicated tooling setup. MUD tooling is often used with prototype molding applications. Learn more about injection molding tooling and processes.

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Our experts help get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

We are ISO 9001:2015, ISO 13485, and AS9100D certified. Only the top shops that apply to become Suppliers make it through our qualification process.

All uploads are secure and confidential