Get high quality tooling parts produced with world-class lead times while Xometry’s project managers work with you to meet your high-volume production needs.

STEP | STP | SLDPRT | IPT | PRT | SAT files

All uploads are secure and confidential.

Xometry’s Instant Quoting Engine is covered by U.S. Pat. Nos. 11,086,292, 11,347,201, 11,693,388, 11,698,623, 12,099,341, and 12,189,361. Other patents pending.

We are here to provide personalized support with getting projects off the ground and see them through to their final vision! We understand that fully realizing a product demands volume, strict schedules, logistics, and reasonable pricing.

Our production injection mold tooling services complement many of our other services, such as prototype molding and bridge tooling, which our customers use to get to a production-ready stage. Below are just some of the advantages you can expect by working with Xometry on your high-volume production needs:

Upload your files to the Xometry Quote Engine. Our team will consult with you to ensure your specifications, lead time, and price fit your project needs. We will provide a DFM report for approval before kicking off tooling.

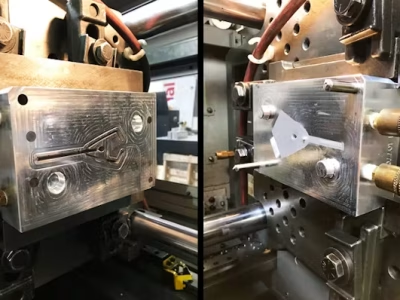

Once your project is kicked off we will build a high-quality injection mold. After the mold is created we will send out part samples, called T1s, for approval.

Once samples are approved, we move forward with production and deliver parts. You own your tool and can easily re-order as needed to meet demand.

While a production tool may be more of an investment when compared to tooling optimized for prototyping or limited volume production, it is good to understand what sets them apart. Xometry and its manufacturing partners incorporate industry-leading techniques and processes with its high-volume injection mold tooling. The chart below offers a quick comparison to our other tooling services and helps highlight some of the advantages typically associated with a tool designed for high-volume production.

| Capability | Production Tool | Bridge Tool | Prototype Tool |

|---|---|---|---|

| Gating - Edge, fan, direct | ✔️ | ✔️ | ✔️ |

| Family tooling | -- | ✔️ | ✔️ |

| SPI-A, -B, -C, and -D surface finishes | ✔️ | ✔️ | ✔️ |

| Mold-Tech and custom mold texturing | ✔️ | ✔️ | -- |

| Gating - Hot runners / hot manifold systems | ✔️ | ✔️ | -- |

| Engineered materials including filled abrasive materials | ✔️ | ✔️ | -- |

| Multi-Cavity Molds | ✔️ | ✔️ | -- |

| Class 102 & 103 molds | ✔️ | ✔️ | -- |

| Class 101 molds | ✔️ | -- | -- |

| Gating - Sequential valve gates | ✔️ | -- | -- |

| Automatic lifters and slides | ✔️ | -- | -- |

| Gas assisted molding | ✔️ | -- | -- |

| Simulated mold flow / knit analysis | ✔️ | -- | -- |

| Repeatable high-volume production runs | ✔️ | -- | -- |

| Range of Suitable Cycles | 500,000 - 1,000,000+ | 25,000 - 500,000 | < 25,000 |

✔️ = Typical or suitable at high-volume

— = Not typical or recommended at high-volume

Xometry is ITAR-registered and certified to ISO 9001:2015, AS9100D, IATF 16949:2016 and ISO 13485:2016. Our diverse manufacturing suppliers have the certifications you require.

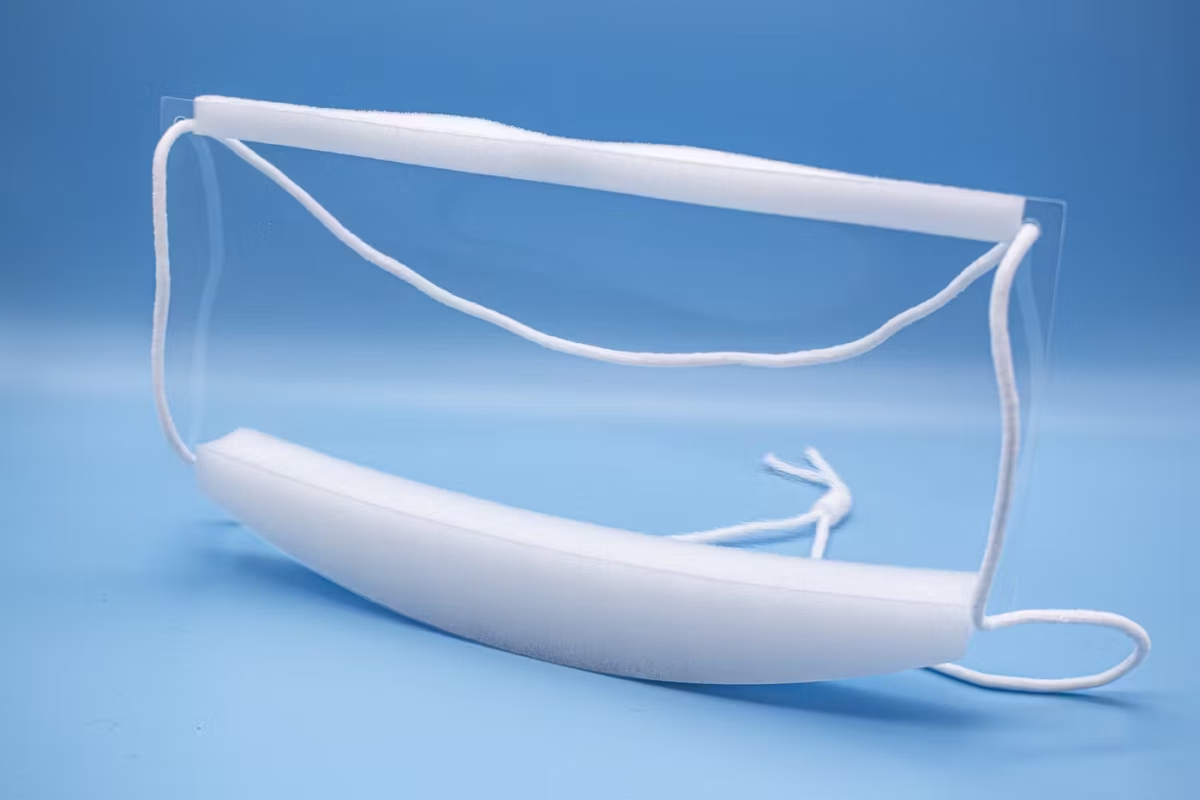

Injection molding is used across various industries, including aerospace, medical devices, consumer goods, energy, electronics, automotive, robotics, toys, and more.

After your tool has been made and samples have been approved, production will commence. The average lead time to produce the remaining parts in the run is 10-15 days.

We offer a wide array of materials, including the most commercially available resins and engineering materials! We can also source custom materials upon request. Read more about choosing the right injection molded plastic.

Yes, most of the time, if they’re in the same family of resins (i.e., two grades of ABS). We can also run different colors of the same material in the same mold. Changing to glass-filled or drastically different materials may present some potential concerns, which our engineers will be happy to work with you on. A purge charge is added to your order when changing materials or colors in the same order.

At Xometry, our customers own their injection mold tools! After a run is complete, the tool will remain at our facilities. Tools can be shipped to you upon request; however, you will be responsible for any associated shipping and packaging costs. Our engineers will work with you regarding tool compatibility with your equipment if you’re unsure.

Exact shipping costs are calculated once the order is kicked off. We need to determine the facility and location from which the parts will ship and work out the size, weight, and packaging requirements. We can ship on a provided DHL, UPS, or FedEx shipping account or provide a shipping quote on our account.

After receiving the order, the statement of work is reviewed by one of our manufacturing engineers. A case manager is assigned, and an appropriate manufacturing supplier is identified. A comprehensive DFM/PEG report is created and provided for approval. Upon approval, tooling and mold production is commenced. T1 samples are produced and shipped for approval. Upon approval, production begins.

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Our experts help get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

We are ISO 9001:2015, ISO 13485, IATF 16949:2016 and AS9100D certified. Only the top shops that apply to become Suppliers make it through our qualification process.

All uploads are secure and confidential