Packaging Engineering & Drop Test

📦 Packaging BOM 🧩 Foam CAD 🪵 Pallet Patterns

🔄 Returns & Repair Packaging

CNC / Die-cut Foam Inserts

ISTA & Vibration Testing

Pallet Patterns & Cube Optimization

Packaging Strategy for Mechanical Parts

How We Approach Packaging For Mechanical Parts

We start from the part level—mapping fragile zones, mounting points and cosmetic surfaces—then design a protection strategy that balances material cost, freight cube and handling risk. Prototypes are lab‑tested and iterated until acceptance criteria are met for your transit lanes.

Key Benefits

Lower damage & returns, validated protection for intended lanes, supplier‑ready pack specifications, and optimized freight cost through right‑sized packaging and palletization.

Packaging Capabilities

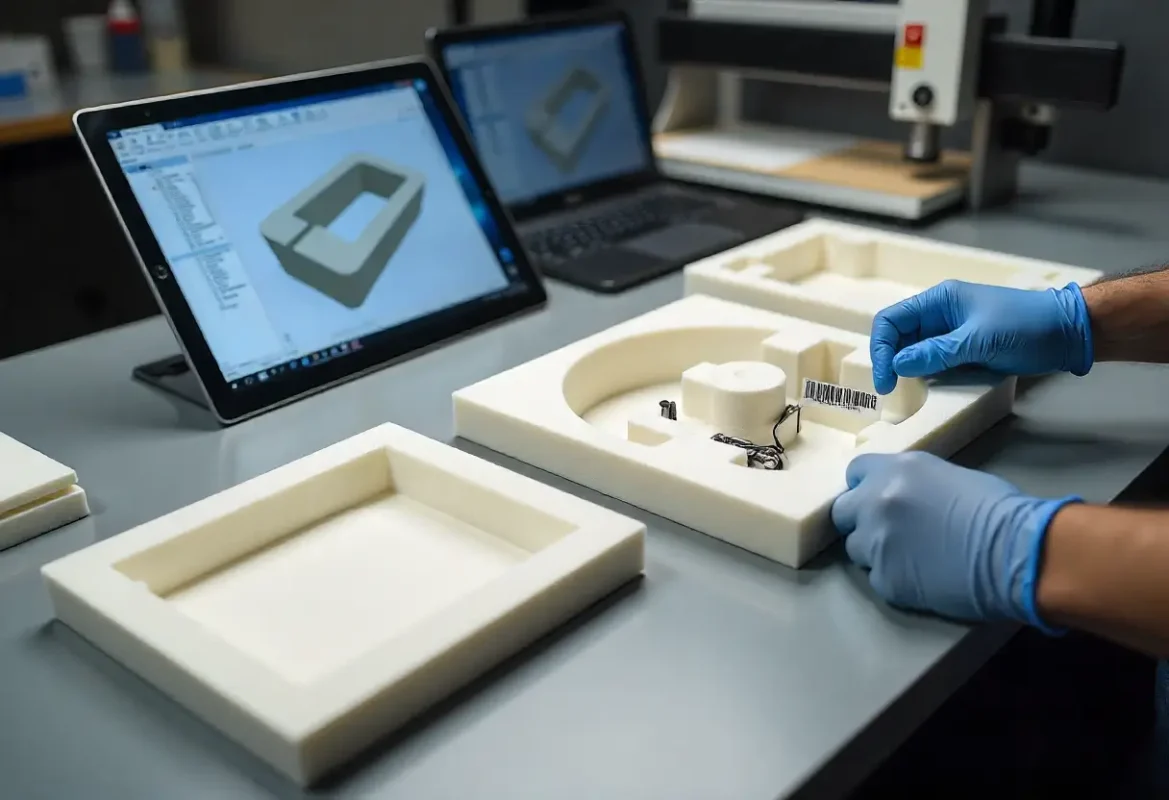

Foam & Tray Design

Custom CNC urethane, die‑cut PE/EPE and molded foam design for fragile or high‑value parts.

Returnable & Kitted Trays

Pallet & Carton Optimization

Packaging BOM & Supplier Kit

How Packaging Engineering Flows End‑to‑End

Intake & Fragility Assessment

Capture CAD, mass, mounting points, cosmetic targets and lane expectations to set protection goals.

Protective Concept

Choose foam type, tray geometry and outer box composition based on test and cost targets.

Prototype Pack & Lab Test

Build prototype packs and run ISTA drops, vibration and compression tests; iterate design as needed.

Supplier Handover

Deliver pack drawings, BOM, supplier sources and pack instructions; qualify pack in the first shipments.

Typical Timeline Examples

We operate ISTA/ASTM‑style lab sequences and custom transit simulations for parcel, unitized and palletized shipments. Tests are selected by lane, unit value and damage risk profile.

| Test | What It Simulates | When To Use |

|---|---|---|

| Drop Sequence | Corner, edge and flat drops representative of manual handling | All packaged units; critical for fragile components and cosmetics |

| Random Vibration | Truck/air vibration profiles that cause loosening or fretting | Long road or air lanes, stacked pallet scenarios |

| Compression / Stacking | Pallet or carton compression under warehouse stacking | High stack height distribution chains and ocean shipments |

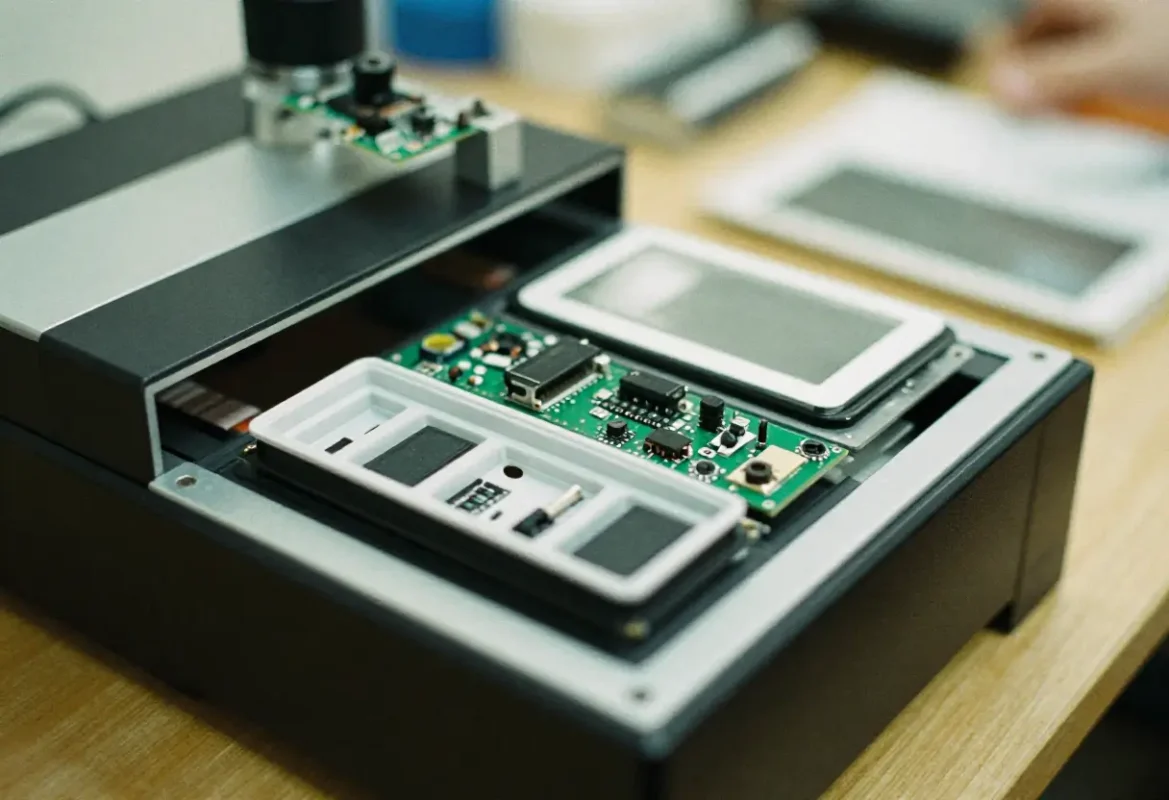

| Combined Environment | Climatic plus mechanical stresses (humidity/temperature + vibration) | Electronics, plated surfaces, or long transit time lanes |

Materials & Typical Pack Types

EPE / PE Foam

Cost‑effective cushioning for many electronics and subassemblies.

Urethane (CNC)

High performance and tightly supporting shapes for heavy/hard parts.

Corrugated Cartons

Right board grade selection to meet compression & stacking needs.

Returnable Trays

Durable trays for repair pools and high‑volume service workflows.

Deliverables & Outputs

Packaging BOM & Supplier List

Componentized BOM (boxes, foam, tape, labels) with supplier recommendations and lead times.

Foam CAD & Cut Patterns

DXF/CAD files for CNC, die‑cut patterns and material specification sheets.

ISTA Test Report & Pack Validation

Test summary, measured accelerations/impacts, photos and acceptance criteria for the target lanes.

Performance Targets

Damage Rate

Target < 0.5% after validation

Cube Utilization

Target > 85% effective

Pack Time

Operator pack standard time documented for throughput

Example: Reducing Damage on High‑Value Assemblies

We redesigned the pack for a precision power module—introducing a CNC urethane cradle, corner blocks and improved carton class. After ISTA 3B validation and first shipments, damage rate fell from 4.5% to 0.3%, and freight cube improved 10% through orientation changes.

Example: Reusable Tray Program

A serviceable module was migrated to a returnable tray pool. Upfront NRE and logistics were offset by a 30% reduction in per‑unit packaging cost over the first 18 months and faster repair turnaround times.

Packing Program Starter Checklist

| Artifact | Purpose |

|---|---|

| Part fragility map | Identify hot spots and required protection |

| Prototype foam CAD | Supplier-ready insert designs |

| ISTA test plan | Define sequences per transit lane |

| Pallet & carton pattern | Optimize cube and compression |

| Packaging BOM | Supplier sourcing & cost |