Xometry provides tube laser cutting for metal rectangular, square, and round tubes.

STEP | STP | SLDPRT | IPT | X_T | X_B | CATPART | PRT | SAT | JT files

All uploads are secure and confidential.

Xometry’s Instant Quoting Engine is covered by U.S. Pat. Nos. 11,086,292, 11,347,201, 11,693,388, 11,698,623, 12,099,341, and 12,189,361. Other patents pending.

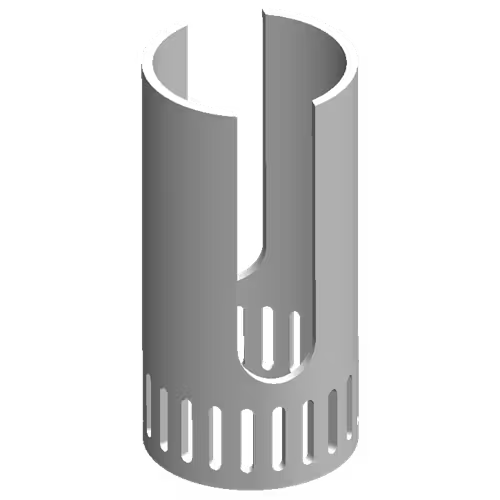

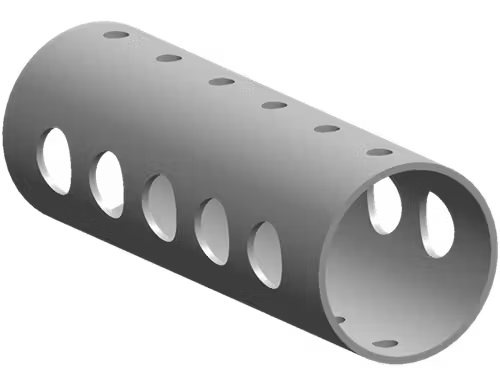

Laser tube cutting is the process by which tube stock material is selectively cut to form various shapes, holes, designs, and/or channels using a controllable precision laser. The stock material (tube/pipe) is held in a controllable lathe, where the tube will rotate in line with the design specifications as the laser makes cuts. Laser tube cutting can create through-holes of any shape as small as the wall thickness of the material and is also often used to cut channels that allow for easy bending and welding of the tube for angled tubing.

Xometry offers an extensive range of laser tube cutting services with instant online pricing, DFM, and lead times. Laser types utilized include fiber laser or CO2 lasers, depending upon the material and application, allowing for very tight tolerances and the ability to cut through wall thicknesses up to 1/2“. Using Xometry’s online quote engine, it is simple to start a quote for your next laser tube cutting project, upload your 3D CAD, and select from our drop-downs to create your quote.

Our project managers and experts are here to assist you along the way with any questions or concerns, ensuring we meet your unique needs while providing a fast and easy manufacturing experience.

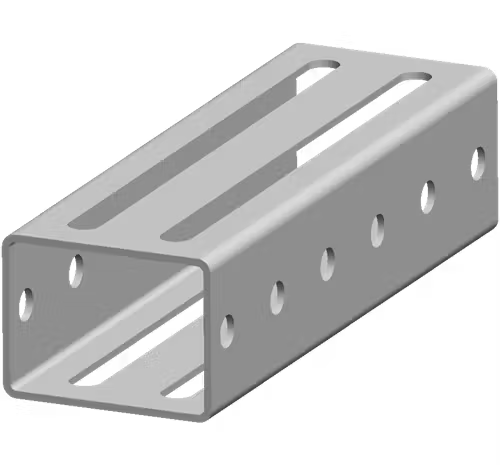

Our laser tube cutting service can cut round, square, or rectangular tubes with a variety of sizes and wall thicknesses. Kerf sizes vary based on the specific material, laser type, laser power, and operation parameters but are overall much thinner than traditional cutting methods, reducing material waste.

Review Xometry’s Standard Tube Sizes for a comprehensive list of available tube stock.

Tolerances are outlined in Xometry’s Manufacturing Standards for Tube Cutting

Laser tube cutting systems have settings for handling tubes of various shapes and profiles. These include round, square, and rectangular tubes.

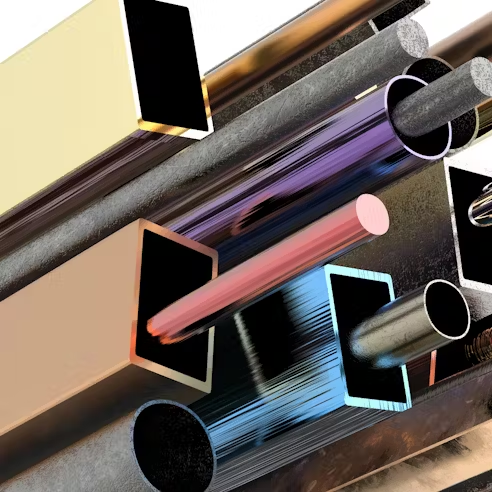

The following materials are available for tube cutting.

| Material | Round Tube | Rectangular Tube | Square Tube |

|---|---|---|---|

| Aluminum | 6061, Extruded 6061, Drawn | 6061, Extruded | 6061, Extruded |

| Stainless Steel | SS 304, Welded SS 304, Seamless SS 316, Welded SS 316, Seamless | SS 304, Welded SS 316, Welded | SS 304, Welded SS 316, Welded |

| Alloy Steel | Steel A513 Type 1, HREW Steel A513 Type 2, CREW Steel A513 Type 5, DOM Steel 4130 (Chromoly), Seamless | Steel A513 Steel 4130 (Chromoly), Cold Drawn Seamless | Steel A513 Steel 4130 (Chromoly), Cold Drawn Seamless |

See our standard tube sizes page for more details.

The main types of laser tube cutting machines vary based on application and laser type. Combination tube/flat sheet laser cutters are one of the most common machines used for laser tube cutting, but are generally used for smaller jobs and are multipurpose machines (i.e. they can also cut flat sheet parts). Self-contained laser tube cutters are dedicated tube cutting systems that are only specified for tube cutting applications, where they can work with nearly any tube shape (round, rectangular, octagonal, etc.) in long stock lengths (3+ feet or more).

Laser tube cutters can use fiber lasers or CO2 lasers based on the needs of a project. Fiber lasers are compatible with a variety of materials and are generally considered the most versatile laser type, while C02 lasers are designed to be an upgrade from plasma cutters, and are best for niche materials such as titanium due to their enhanced gas coverage over fiber lasers. Both laser types offer comparable power levels. In either case, both cutting processes are well suited for metal fabrication and can eliminate the need for secondary operations.

Lasers are specified based on their wattage, where a higher wattage offers deeper and more sustained cuts. Laser tube cutters are also specified based on the size of material they can handle (max sheet/tube size, max material weight), the assist gas required (nitrogen, CO2, etc,) the motor electrical requirements (3-phase VAC, etc.), repeatability, and other model-specific criteria. Some laser tube cutters come with built-in conveyors or stock handling machinery which automatically feeds the tube into the cutting portion of the system, providing semi-to-fully automated operation.

Here are the advantages of the laser tube cutting process:

The disadvantages or limitations of laser tube cutting include the following:

Access the capacity of hundreds of laser tube cutting suppliers through our easy-to-use platform.

We are ISO 9001:2015, ISO 13485, IATF 16949:2016, and AS9100D certified. Only the top shops that apply to become network suppliers make it through our qualification process.

Our team of Solutions Engineers and Process Specialists are available to support you and provide answers to all of your fabrication and manufacturability questions.

All uploads are secure and confidential