Failure Analysis & Redesign

A practical, test‑driven approach to find root cause, implement corrective redesigns and verify results so failures do not recur in production. We combine on‑site field data, lab reproduction, DFMEA methods and engineering redesign to deliver durable fixes and handover packages for production.

📝 8D / 5‑Why Reports ⚙️ DFMEA / PFMEA Updates

📐 Corrective Design Drawings 📊 Verification Test Reports + Control Plans

Outcome

Repeatable Fixes • Verified • Production‑Ready

From Failure to Verified Fix

We help teams move beyond temporary fixes by identifying true root causes, implementing corrective redesigns, and validating results with production-ready controls.

Why Address Failures Systematically

Ad hoc fixes risk recurrence, warranty exposure and supplier churn. We apply structured root cause methods and link corrective actions to manufacturing controls and verification so results hold in production.

When to Engage Us

Early field anomalies, first‑off failures in EVT/DVT, repeat defects in pilots, unexplained warranty returns, or when supplier returns lack evidence of permanent corrective action.

Who We Work With

Design engineers, test labs, supplier quality teams and program managers who need a single accountable engineering team to lead investigation, redesign and verification.

Investigation → Corrective Redesign → Verified Handover

Intake & Evidence Collection

Collect failed parts, assemblies, process records, supplier data and field logs. Define failure symptoms, occurrence rate and risk to program.

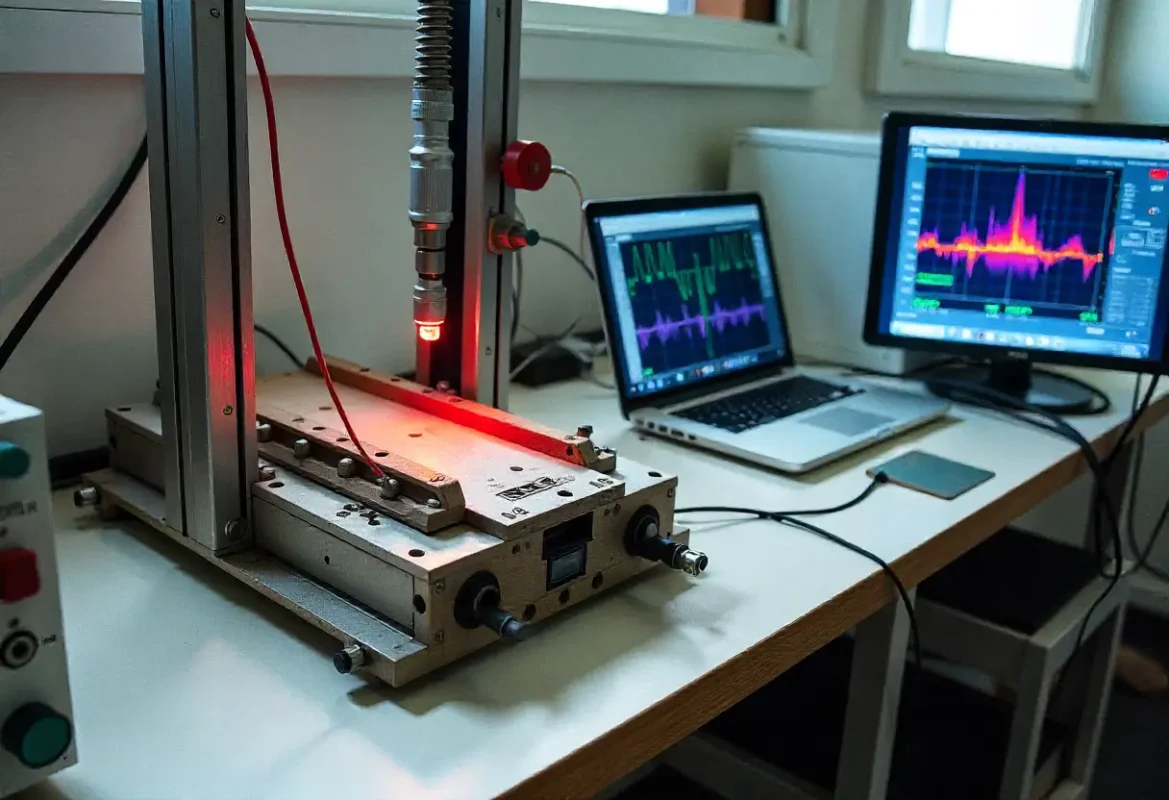

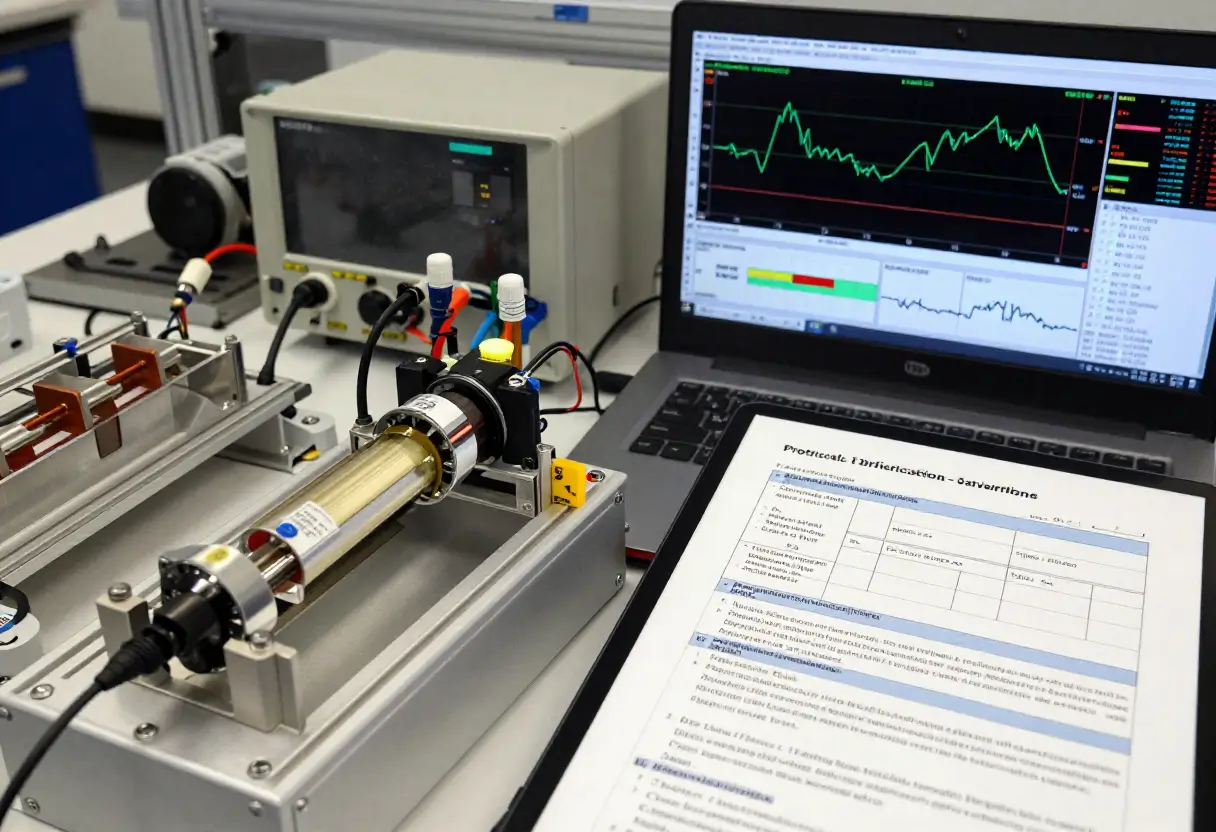

Replication & Lab Reproduction

Attempt to reproduce the failure in controlled conditions to validate hypotheses and to enable repeatable testing of corrective options.

Root Cause Analysis

Apply 5‑Why, 8D, DFMEA and evidence‑based analysis to identify primary, contributing and systemic causes.

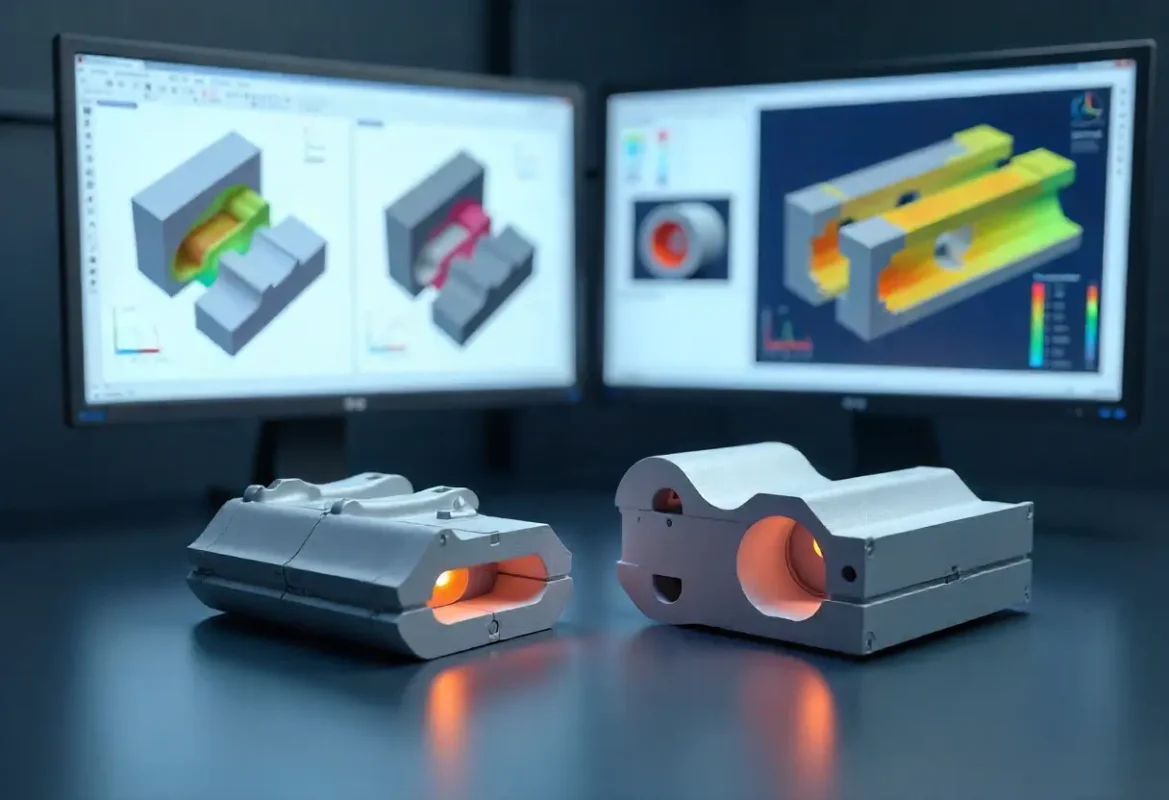

Corrective Redesign

Implement design changes, process controls, tooling updates or material substitutions and document engineering change with justification and impact assessment.

Verification & Handover

Run verification builds, durability and environmental tests; produce FAI/PPAP deliverables, control plans and supplier instructions for SOP.

Methods & Tools We Use

Structured Problem Solving

DFMEA / PFMEA

Test & Reproduction

Methods & Tools We Use

Geometry & Strength Fixes

Material & Surface Changes

Change alloys, specify coatings, adjust heat treatment, or change surface finish to mitigate wear, corrosion and contact degradation.

Process & Assembly Controls

Testing & Verification

Verification is not optional. We combine lab testing (mechanical, thermal, environmental), instrumented replication, and statistical runs to demonstrate that corrective actions eliminate root cause and do not introduce new risks.

Deliverables & Production Handover

Investigation Report

Detailed timeline, evidence, failure modes, root cause statements and recommended corrective actions with success criteria.

Corrective Design Package

Engineering drawings, BOM updates, revised CAD, and implementation notes for tooling, assembly and inspection.

Verification Test Report

Replication protocols, instrumentation data, pass/fail criteria and statistical confidence for the corrective action.

Production Controls

FAI/PPAP package, PFMEA updates, control plan, SPC templates and supplier instruction package for SOP release.

Artifact SLAs & Typical Contents

| Artifact | Contents | Typical SLA |

|---|---|---|

| 8D / RCA Report | Containment, root cause, corrections, verification plan | 3–10 business days (scope dependent) |

| Corrective Drawings | Revised geometry, tolerances, notes for supplier release | 3–14 days |

| Verification Protocol & Data | Test setup, instrumentation, results and conclusion | 1–3 weeks |

| Production Handover Package | FAI/PPAP, PFMEA, control plan and SPC templates | Aligned to PVT / SOP schedule |

Supplier & Quality Integration

We work directly with supplier engineering and quality teams to implement changes, update process controls, and supervise first article runs when required. Our goal is a single auditable path from failure to validated SOP.

If on‑site support is required, we provide field engineering to collect evidence, witness tests, and accelerate closure.