Engineering Validation EVT DVT PVT

📐 Metrology + CMM 🌡️ Environmental / Reliability Testing

📑 FAI / PPAP / Cpk 📦 Production Handover

Validated Builds • FAI/PPAP • Process Windows

Structured Engineering Validation

EVT - Engineering Validation Test

Short, fast builds using prototype and bridge production methods to confirm form, fit, basic function, and to uncover early design issues. Rapid iteration and close engineering feedback are the focus.

DVT - Design Validation Test

Production‑intent materials and assemblies undergo full functional testing, environmental stress testing, and tolerance verification. DVT confirms the design against specs and refines the manufacturing approach.

PVT - Process Validation Test

Pilot runs off near‑hardened lines to establish process windows, capability (Cpk), FAI/PPAP, packaging validation and final SOP readiness. This stage proves the manufacturing system, not just the design.

Validation Workflow

Plan & Protocol

Create build plans, sampling, acceptance criteria, test protocols and metrology checklists before the first build.

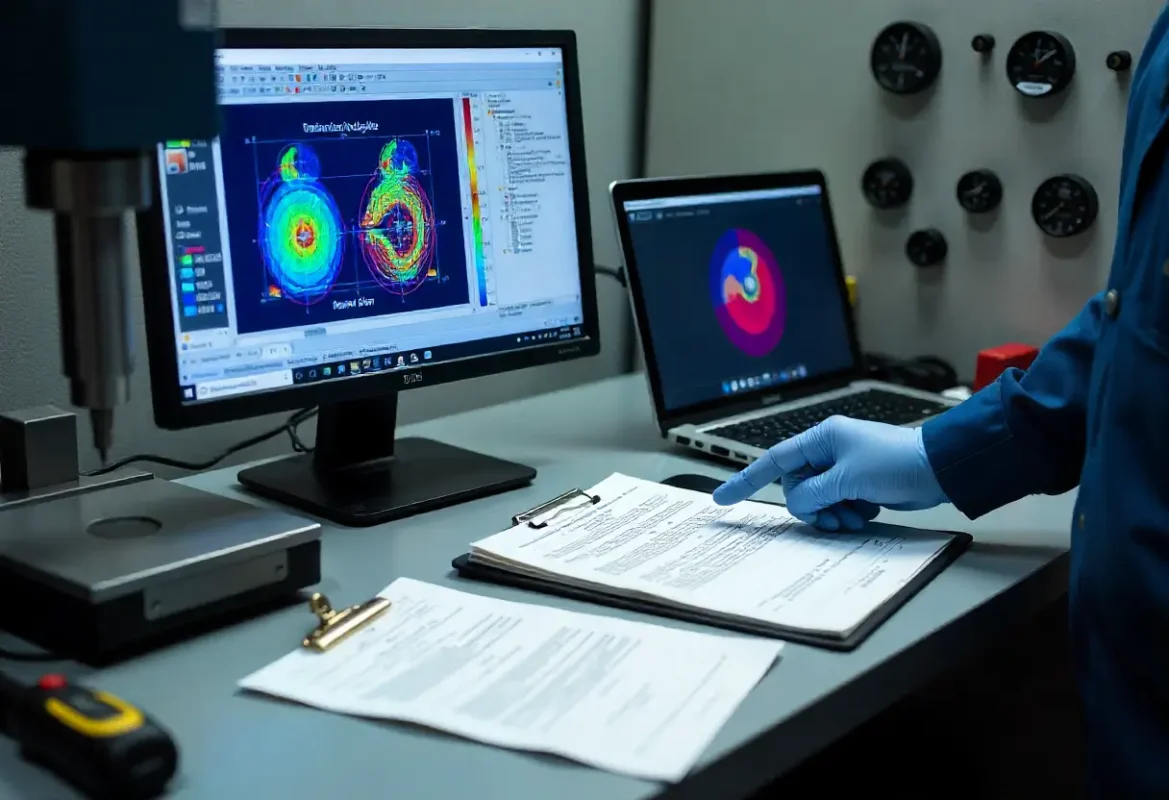

Build & Inspect

Execute builds, capture CMM data, photos and dimensional reports; log nonconformances and dispositions.

Functional & Environmental Testing

Run thermal, vibration, shock, humidity and lifecycle tests aligned to product requirements and regulatory needs.

Analysis & Iteration

Analyze failures, perform root‑cause investigation, implement design or process corrective actions and revalidate.

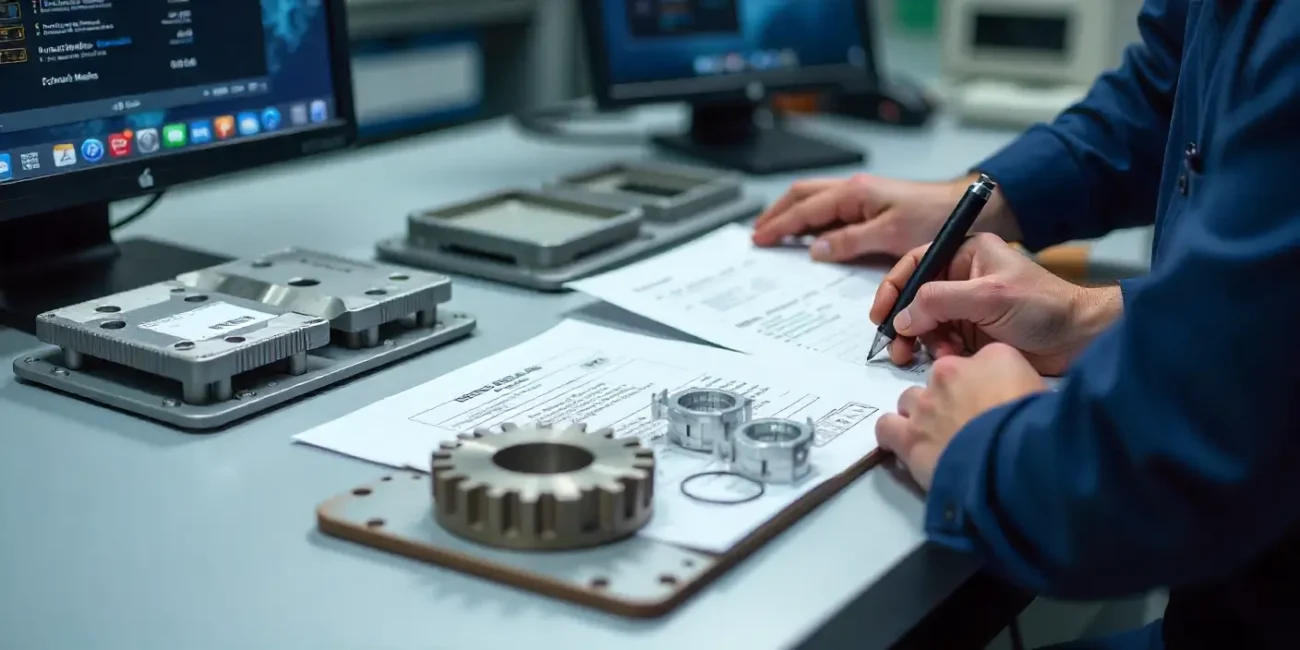

Qualification & Handover

Complete FAI/PPAP, Cpk analysis, control plan and supplier instruction sets for SOP release and ongoing monitoring.

From Prototypes to Volume Key Services

Dimensional & Metrology

Environmental & Reliability

Functional & Performance

FAI / PPAP & Process Qualification

SPC, Cpk & Process Windows

Activity Timelines & Typical SLAs

| Activity | Representative SLA | Notes |

|---|---|---|

| Rapid proto part | 2–7 days | Machined, printed or bridge tooling |

| EVT build | 1–3 weeks | Small batch, iterative fixes expected |

| DVT build & testing | 2–6 weeks | Full functional and environmental testing |

| PVT / pilot run | 2–8 weeks | Process windowing, PPAP/FAI and packaging validation |

| Full SOP ramp | varies | Based on production volume and tooling |

Roles & Responsibilities

We can operate as your engineering lead or as an embedded partner with your team. Typical responsibilities: program engineering (YourBrand) manages builds, metrology, testing coordination, NPI PM and FAI deliverables. Your team provides acceptance criteria, final approvals and commercial decisions.

Snapshot

EVT → 2 builds, 10 units each. DVT → 30 units in production intent. PVT → 200 pilot parts, full PPAP and supplier handover.

Case Study Power Electronics Inverter

Problem: early EVT units showed thermal runaway in high ambient conditions. Approach: EVT builds with thermal mapping identified hotspot; CAE correlated with flow imbalance; redesign of cold plate manifold and rebalancing of flow solved issue. DVT confirmed robust performance across environmental tests. PVT established process window and Cpk > 1.67 for critical dimensions. Outcome: SOP achieved with no warranty events in year one.