Design Requirements & DFM Guidelines for Manufacturable Products

📐 Geometry + GD&T & Stack‑Ups 🧱 Materials Aligned with Processes

📊 DFM / DFMA Across Multiple Processes 🏭 EVT → MP Requirements Flow‑Down

Clear, Actionable Requirements

Multi‑Process DFM / DFMA

Coordinate requirements across CNC, molding, casting, sheet metal, and assemblies so the full system works together.

Cost & Quality Balanced Early

Why Good Requirements & DFM Save Time and Cost

Reduce Design‑to‑Build Friction

Clear requirements and DFM‑friendly drawings reduce back‑and‑forth, quote ambiguity, and first‑article surprises.

- Well‑defined critical features and tolerances

- Explicit cosmetic and functional zones

- Process‑aware geometry and dimensions

Align Performance, Cost & Risk

Requirements are set with manufacturing realities in mind, balancing performance targets with achievable processes and costs.

- Early trade‑offs across geometry and processes

- Cost and lead‑time impacts considered upfront

- Clear acceptance criteria for each build phase

Enable Stable EVT / DVT / PVT

A consistent requirements and DFM framework lets you move cleanly from prototype to validation to mass production.

- Requirements traced across build stages

- Consistent drawing and spec revisions

- Predictable hand‑offs to suppliers and QA

Core Design Requirement Categories

We structure requirements and DFM reviews around a few key categories that determine manufacturability, reliability, and cost.

Geometry & Tolerances

- Critical dimensions and GD&T

- Datum structure and stack‑ups

- Minimum feature sizes and wall thicknesses

Material & Process

- Alloy, plastic, and rubber selection

- Compatible manufacturing routes

- Thermal, mechanical, and chemical limits

Surface & Cosmetics

- Finish type, color, and texture

- Ra and functional surface requirements

- Defect and blemish acceptance criteria

Assembly & Service

- Fastening and sealing strategies

- Access, alignment, and orientation

- Disassembly and field service needs

Typical Design Requirements We Help Optimize

We review your drawings, models, and specs and suggest changes that improve manufacturability while preserving function and quality.

| Requirement Area | What We Look At | Typical DFM / Guideline Focus |

|---|---|---|

| Geometry & GD&T | Critical dimensions, datums, and stack‑ups across parts and assemblies. | Ensure geometry matches process capability, simplify features, and balance tolerances vs. cost. |

| Materials & Processes | Chosen alloys, plastics, rubbers, and planned manufacturing routes. | Verify material/process fit, suggest alternates, and align specs with thermal, mechanical, and cost needs. |

| Surface & Cosmetic Specs | Finish type, Ra, color/texture, and cosmetic acceptance criteria. | Zone cosmetic requirements, match finishes to processes, and avoid unnecessary cosmetic risk/cost. |

| Assembly & Service | Fastening, sealing, access, orientation, and service operations. | Design for easy assembly, error‑proofing, and maintainability with minimal tools and steps. |

DFM Guidelines by Process

Each manufacturing process has its own “rules of thumb.” We help you apply them early so your designs are a good fit for your chosen processes.

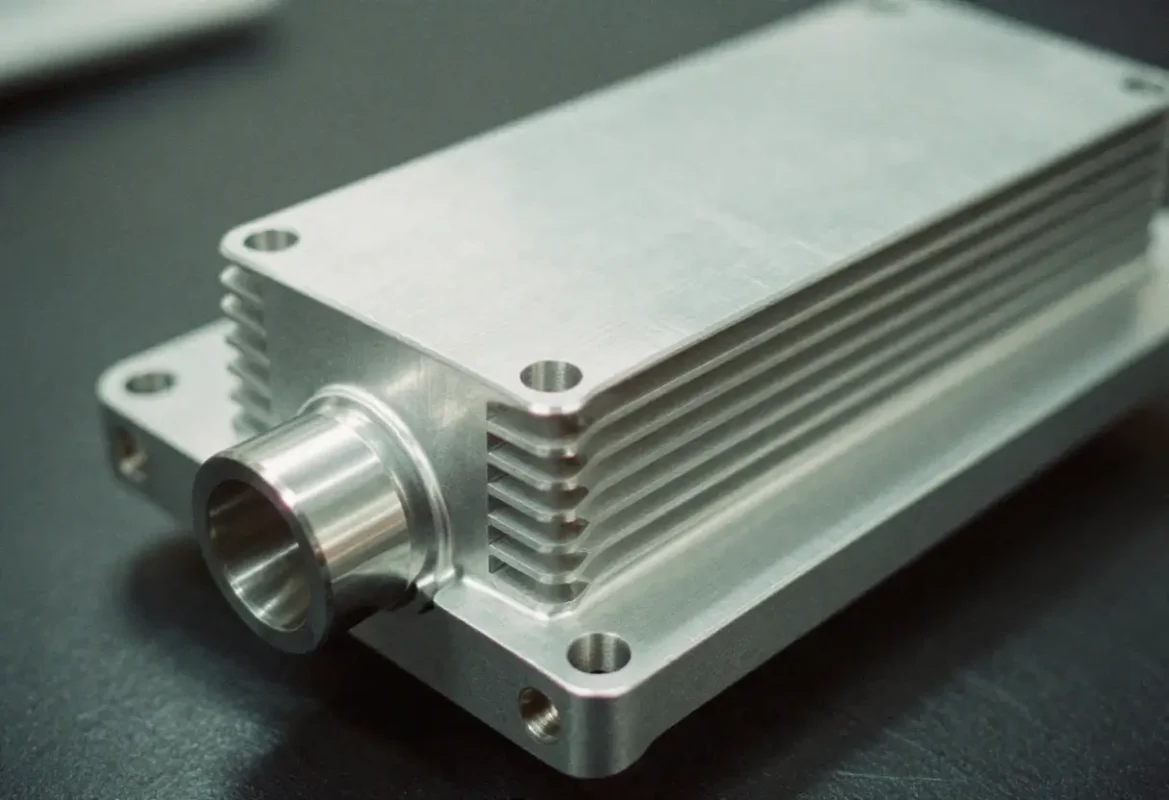

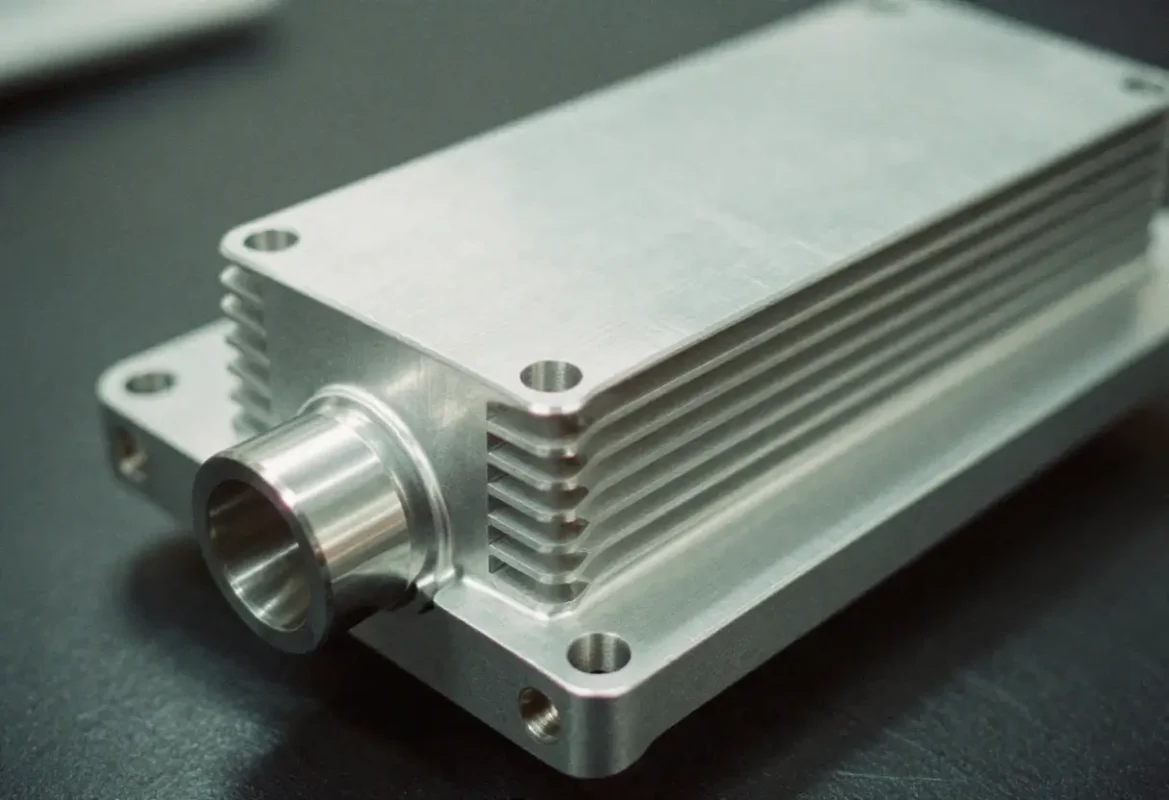

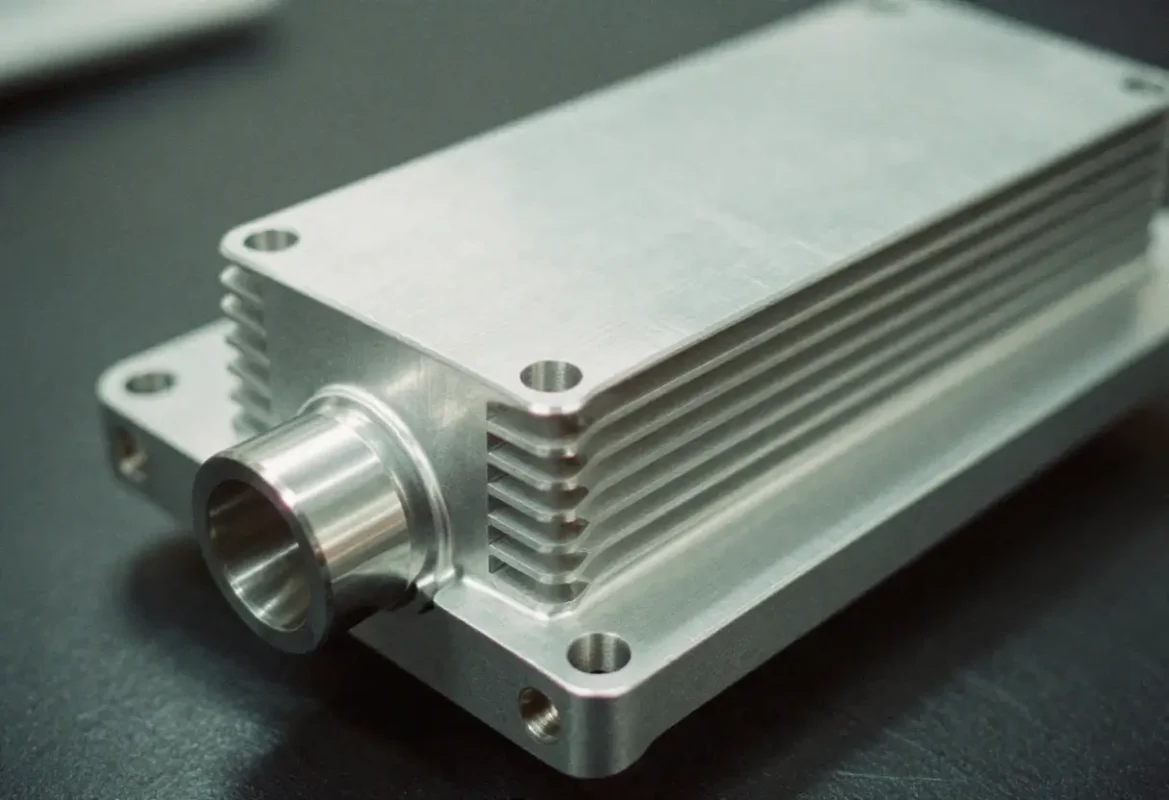

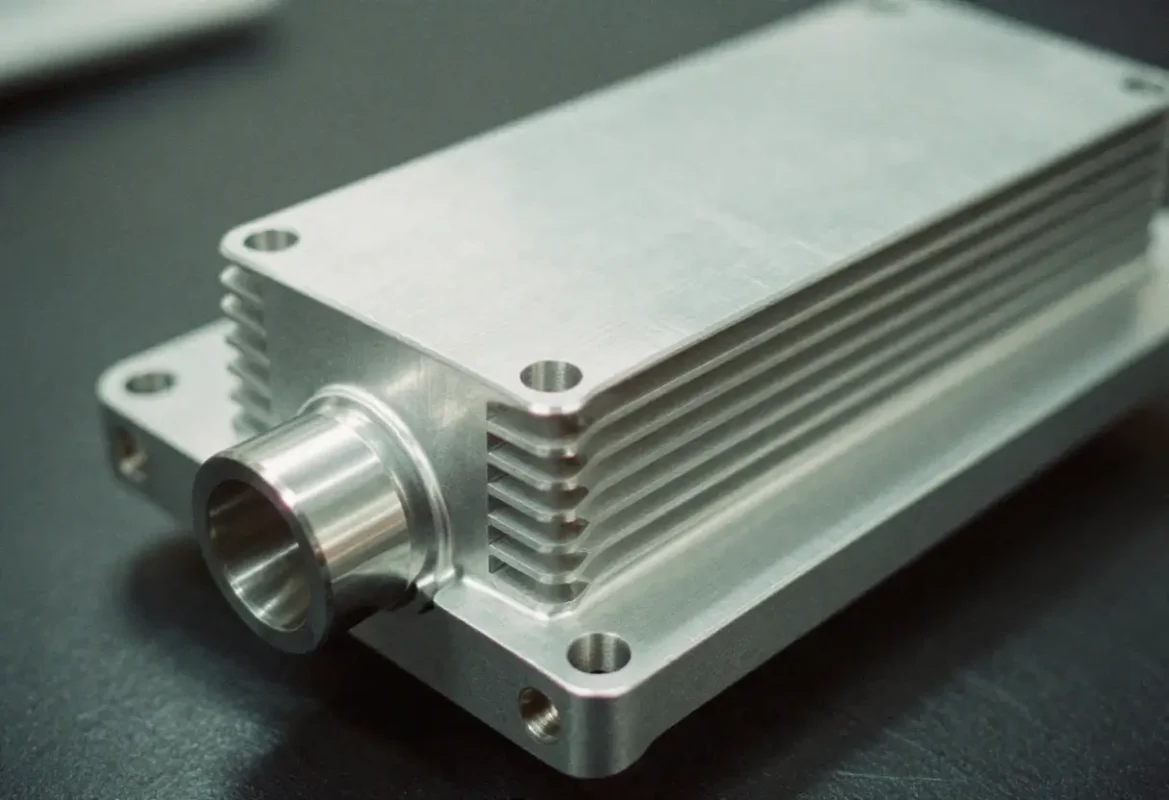

CNC Machining

- Minimize deep pockets and very small radii where possible

- Align features with standard tool sizes and approaches

- Limit extremely tight flatness and parallelism requirements

Molding & Casting

- Add draft, uniform wall thickness, and fillets

- Plan parting lines, gates, and ejector locations

- Design ribs and bosses for flow and strength

Sheet Metal & Fabrication

- Respect bend radii and minimum flange lengths

- Align tabs, slots, and holes with tooling constraints

- Avoid unnecessary bend/feature complexity

Rubber & Silicone

- Define squeeze, compression, and interference correctly

- Control flash and parting surfaces where cosmetics matter

- Match durometer and material to temperature and media

Thermal Interfaces

- Specify flatness and roughness for TIM performance

- Define clamp force and contact area requirements

- Coordinate with heatsinks, cold plates, and PCBs

Assembly & Testing

- Design for simple, repeatable assembly steps

- Build in orientation and error‑proofing features

- Plan test points and access for validation

Requirements, Quality & Documentation

Good design requirements and DFM only work if they’re documented and maintained. We help you tie them into quality and change‑control systems.

Drawing & Spec Management

Consistent title blocks and revision schemes Clear notes on critical features and inspection levels Standardized call‑outs for finishes and treatments

Quality Planning

Control plans aligned with design intent FAI and PPAP based on critical characteristics Measurement and test methods tied to requirements

Measurement and test methods tied to requirements Change Control

Engineering change orders with requirement impact Cross‑functional review of DFM implications Traceability from issue to updated specs

When to Apply DFM in Your Development Cycle

DFM is not a one‑time event—it’s a thread that should run through every major phase of your program.

Concept & Architecture

- High‑level process selection and part count

- Rough geometry limits and interface definitions

- Initial cost and risk assessment

Design & EVT

- Apply process‑specific DFM rules to CAD

- Prototype parts that are close to production intent

- Lock critical requirements before tooling

DVT / PVT

- Confirm capability, yield, and cosmetic performance

- Refine tolerances, finishes, and inspection plans

- Finalize control plans and PPAP where needed

Mass Production

- Monitor scrap, rework, and escape issues

- Run targeted DFM/DFMA cost‑down projects

- Adjust requirements as designs evolve

Ready to Tighten Up Your Design Requirements & DFM?

Share your drawings, models, and target processes. We’ll review your requirements, highlight DFM opportunities, and propose a path to production‑ready documentation.

Upload Drawings for DFM Review

Send STEP/IGES/PDF files and basic requirements. Receive structured DFM feedback and suggested changes within a few days.

Run a DFM / Requirements Workshop

Work through one product or sub‑assembly with our team to establish requirements and DFM patterns you can reuse on future programs.

Connect with Cost & Quality Planning

Integrate requirements and DFM with cost, PPAP, and control plans to create a single, coherent product introduction strategy.