STEP | STP | SLDPRT | IPT | X_T | X_B | CATPART | PRT | SAT | JT files

All uploads are secure and confidential.

Xometry’s Instant Quoting Engine is covered by U.S. Pat. Nos. 11,086,292, 11,347,201, 11,693,388, 11,698,623, 12,099,341, and 12,189,361. Other patents pending.

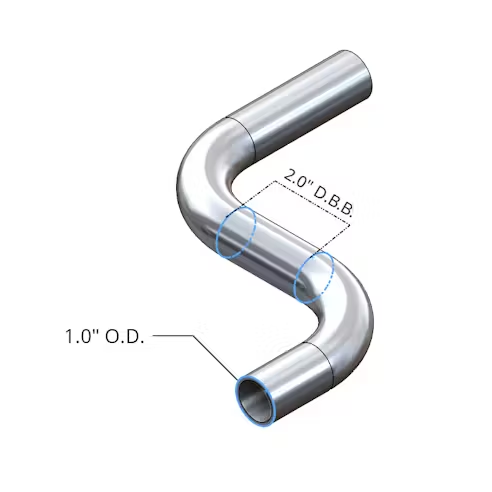

Tube bending is a group of forming processes used to reshape tube or pipe into the geometry required for an assembly. Tube stock is placed into a bending machine and formed against dies and rollers so it follows a controlled bend radius and angle.

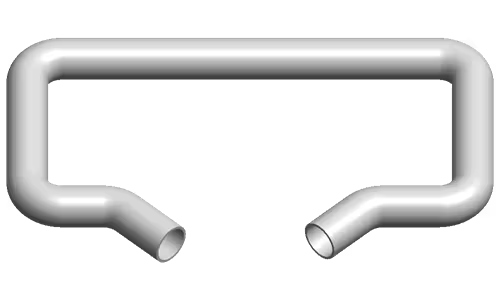

Bends may be single-plane (2D) where all bends remain in one plane, or multi-plane (3D) where bends occur across multiple planes to create complex routing paths. CNC tube bending supports multiple bends in one part, often reducing the need for welded elbows and improving consistency across repeat builds.

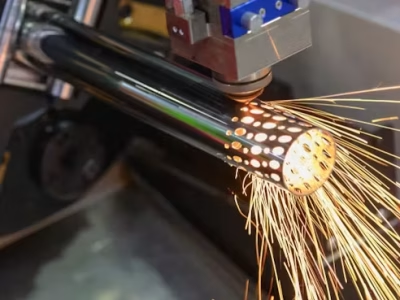

LK Tools supports tube bending for applications ranging from frames and brackets to fluid/air routing and structural assemblies. If your design includes cut features (holes, slots, end profiles), we can also coordinate laser tube cutting so parts arrive ready for assembly.

Our tube bending service supports common industry ranges for round tube bending. Tighter requirements can be reviewed during quoting based on tube diameter, wall thickness, bend radius, and number of bends.

Typical capability range (confirm during quoting):

General tolerance guidance (project-dependent):

If you have critical fit-up dimensions, provide a 2D drawing with bend callouts and tolerance notes so we can confirm feasibility.

LK Tools supports tube bending for custom round tube parts across multiple metals. Availability depends on tube size, wall thickness, and sourcing requirements.

Common material options:

If you require a specific standard, certification, or lot traceability, include that in your RFQ.

Line (optional):

See our standard tube size guidance for common OD/wall combinations.

Welded: Tube formed from rolled sheet and welded along a seam.

Seamless: Tube produced without a welded seam—often selected for higher-performance applications.

Extruded: Tube produced by pushing material through a die (common for aluminum).

Drawn: Tube pulled through a die to improve precision and strength.

DOM: “Drawn Over Mandrel”—welded tube is drawn over a mandrel to improve strength and finish.

HREW: Hot Rolled Electric-Welded—often cost-effective for general structures.

CREW: Cold Rolled Electric-Welded—improved surface/consistency compared with HREW.

Good tube bending results start with bend-friendly geometry. Below are practical DFM tips to help improve manufacturability, reduce deformation risk, and improve repeatability.

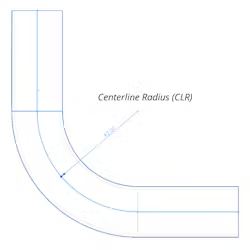

Beyond general guidelines, certain OD-to-CLR combinations are more common and easier to source/tool. If your project allows, selecting a common CLR can improve cost and lead time.

OD to CLR Recommended Combinations (examples):

(Above: Center Line Radius, CLR)

LK Tools supports multiple tube and pipe bending approaches depending on geometry, wall thickness, and cosmetic/functional requirements:

Mandrel bending supports the tube internally during the bend, helping maintain the internal profile and reduce collapse or excessive ovality—especially for thinner walls, larger diameters, or tighter radii.

A common method for accurate, repeatable bends. The tube is clamped and drawn around a bend die. CNC-controlled rotary draw bending is often used for multi-bend parts and production runs.

Uses rollers to create gradual arcs and large-radius bends. It can be useful for sweeping bends but is generally less precise for tight tolerances and complex multi-bend geometry.

Often used for simpler single-bend applications. Because the tube is not supported internally, ovality or deformation may be more likely—especially on thin walls or tight radii.

Tube bending is used across many industries where structural tubes, frames, or routing paths are required. Common sectors include:

Access hundreds of service suppliers through our easy-to-use platform.

We are ISO 9001:2015, ISO 13485, and AS9100D certified. Only the top shops that apply to become network suppliers make it through our qualification process.

Our team of Application Engineers and Process Specialists are available to support you and provide answers to all of your fabrication and manufacturability questions.

All uploads are secure and confidential