All uploads are secure and confidential.

Xometry’s Instant Quoting Engine is covered by U.S. Pat. Nos. 11,086,292, 11,347,201, 11,693,388, 11,698,623, 12,099,341, and 12,189,361. Other patents pending.

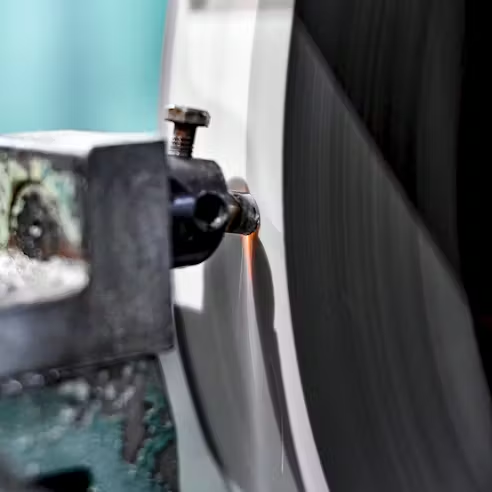

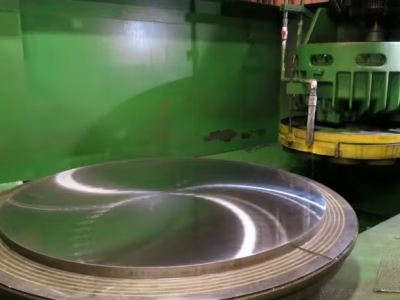

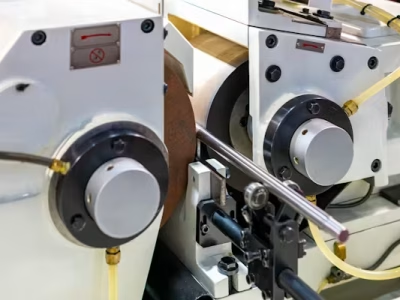

Surface grinding is a precision finishing process used to produce flat, smooth, and dimensionally accurate surfaces. A rotating abrasive wheel removes small amounts of material while the part is held securely on a table (often via magnetic chuck for ferrous materials). Surface grinding is commonly used to control flatness, parallelism, and final thickness, or to create a uniform finish on critical faces.

Surface grinding is often selected after machining or heat treatment when parts need final size correction, improved surface finish, or consistent mating surfaces.

Listed below are some of the materials that accept surface grinding:

Useful for flatness and thickness control when set up correctly. May require attention to wheel selection and fixturing due to material loading.

Can be ground for flatness and surface finish; wheel selection and feeds help avoid smearing.

Commonly ground and generally stable; suitable for flat reference surfaces and mating faces.

A frequent surface grinding material—often for tooling plates, brackets, and machine components.

Grindable, but can require careful process control due to heat and work hardening (grade dependent).

Some engineering plastics can be surface ground for thickness/flatness requirements with appropriate technique.

Possible with correct abrasives and process controls; typically requires careful heat management.

Surface grinding offers several benefits across the manufacturing sector:

Surface grinding removes small amounts of material and can be an efficient finishing step when compared with repeated machining passes (setup dependent).

Surface grinding is commonly used for final correction of thickness, flatness, and parallelism on critical faces.

Produces consistent surface finishes suitable for mating surfaces, sliding interfaces, and cosmetic faces (requirement dependent).

Surface grinding can help achieve tight dimensional control when the part is designed and fixtured appropriately. Include your tolerance targets and inspection requirements in the RFQ.

Listed below are some of the disadvantages of surface grinding:

Surface grinding equipment is very precise and therefore costly.

Residual abrasives embedded in the surface can disrupt the formation of a protective oxide film in stainless steel. This can invite corrosion when equipment is exposed to aggressive environments. These residual contaminants make surface grinding unacceptable as a finishing process for pharmaceutical processing equipment, among other sectors.

Poor coolant supply and/or excessive cut depth can heat the workpiece enough to disrupt previous hardening effects. In the case of slides and plane bearings, that will compromise their resiliency.

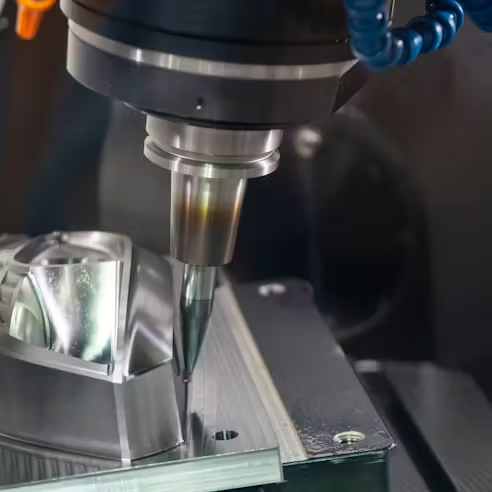

If surface grinding isn’t the best fit, alternatives may include:

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Get started with our easy-to-use platform and let our experts take care of managing the project from locating the right manufacturing partner to delivery logistics.

We are ISO 9001:2015, ISO 13485, and AS9100D certified. Only the top shops that apply to become Suppliers make it through our qualification process.

All uploads are secure and confidential