High-Resolution Prototypes in Days

Free shipping on all US 3D printing orders

STEP | STP | SLDPRT | STL | DXF | IPT | 3MF | 3DXML | PRT | SAT files

All uploads are secure and confidential.

Xometry’s Instant Quoting Engine is covered by U.S. Pat. Nos. 11,086,292, 11,347,201, 11,693,388, 11,698,623, 12,099,341, and 12,189,361. Other patents pending.

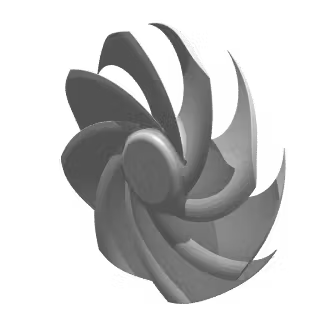

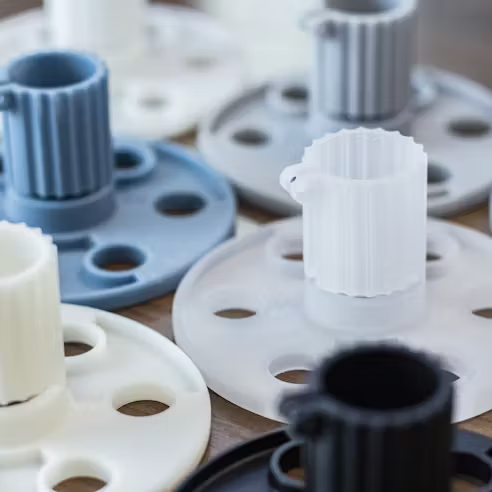

Stereolithography (SLA) is a powerful 3D printing technology that produces extremely accurate, high-resolution parts suitable for end-use applications, low-volume production, or rapid prototyping. At K Tools Inc., we offer over 15 uniquely engineered SLA materials that can help bring your products to market faster.

Supported surfaces will be lightly sanded with 220 or 320 grit sandpaper, then media blasted for a uniform matte finish.

Supported surfaces will be lightly sanded with 220 or 320 grit sandpaper for improved surface quality. Sanding scratches will be visible on supported surfaces.

Supported areas may show small grid-like dots or surface blemishes as a result of support removal.

Available for Accura ClearVue. Only supported surfaces are sanded. Parts will still have visible layering. High gloss clear coat is applied to enhance natural clarity.

Our provides additional SLA finishing options, including but not limited to sanding, polishing, painting, post thermal processing, and plating to meet your needs.

Free shipping available for domestic 3D printing orders

The speed, accuracy, and great surface finish of SLA parts lets product developers create physical snapshots of their designs through the iterative process.

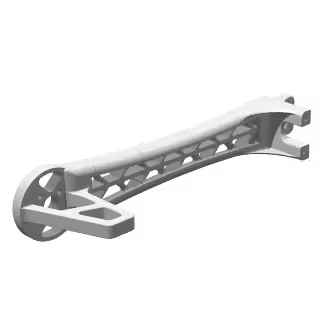

SLA prototyping is a fully-functional prototype, with materials that can simulate polypropylene, polycarbonate, ABS, and rigid composites.

The high accuracy and consistency of SLA makes it an ideal way to build large quantities of discrete or customized parts.

SLA is the ideal choice for 3D printed models that require accurate features and a smooth surface finish. Our stereolithography service offers both standard and high-resolution options for fine detail parts and can produce components up to a 29″ build area. With the ability to produce complex features with good mechanical properties, an SLA print is often used for final fit checks before moving to injection molding.

In addition, our manufacturing partner network allows us to offer a larger variety of materials than many other 3D printing companies. We provide a wide range of brand materials to suit your needs.

Our quick reference guides let you quickly compare different 3D printing processes!

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

We are ISO 9001:2015, ISO 13485, and AS9100D certified. Only the top shops that apply to become Suppliers make it through our qualification process.

All uploads are secure and confidential