Fast-turn injection molding for prototype and pilot builds when timeline matters. LK Tools helps you move from CAD to molded parts with engineering review and a practical tooling strategy.

STEP | STP | SLDPRT | IPT | PRT | SAT files

All uploads are secure and confidential.

Xometry’s Instant Quoting Engine is covered by U.S. Pat. Nos. 11,086,292, 11,347,201, 11,693,388, 11,698,623, 12,099,341, and 12,189,361. Other patents pending.

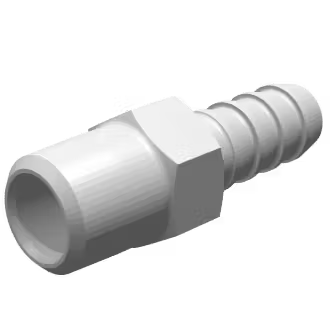

LK Tools offers multiple injection molding paths—from early prototype tools to production-intent molds—so you can match speed, cost, and tool life to your program stage. Quick turn molding is designed for projects that need molded parts quickly for design validation, pilot runs, customer samples, or early production planning.

This service is a strong fit when you need to accelerate development while still using production-grade resins and molded part geometry. During quoting, our team reviews your design for manufacturability and flags any risks (draft, wall thickness transitions, undercuts, gating considerations) before tooling begins.

Key benefits (bullets):

Use this section to highlight a customer story how a team accelerated development using quick turn molding, validated assemblies, and then scaled into repeat production.

With quick turn molding, the goal is to shorten lead time by keeping tooling and process requirements aligned to a fast, repeatable workflow. To ensure the service is the right fit, confirm the following during quoting:

For projects requiring more customization, higher tool life, or specialized requirements, consider our full Custom Plastic Injection Molding Service options.

Insert your criteria table here (lead-time tiers, max part size, mold type, shot count targets, etc.). If you share your actual table values, I can rewrite the labels and descriptions to match your real service while keeping it clean and original.

Footnote (keep idea, rewrite):

Quoting response times depend on business hours and project complexity. Requests received outside business hours are handled the next business day.

For quick turn projects, we recommend selecting materials that are widely available and proven in molding. If you need a specific resin grade or compliance requirement, include it in your RFQ so we can confirm availability and lead time. Customer-supplied materials may be possible upon review.

Lead time depends on part geometry, tool complexity, resin availability, and finishing requirements. We’ll confirm an estimated schedule during quoting.

Yes. We review key molding risks (draft, undercuts, wall transitions, ejection, gating considerations) and may recommend changes to improve results.

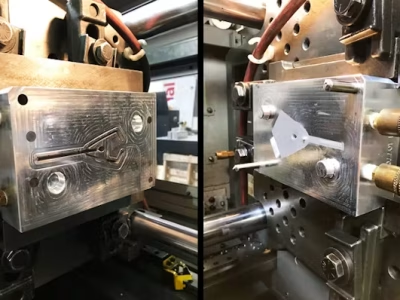

We confirm requirements, finalize DFM/tooling approach, build the tool, produce first samples for approval, then proceed to molding for the required quantity.

Minimums depend on tooling approach and resin selection. Share your target quantity and we’ll recommend the best option.

Injection molding is widely used across consumer products, industrial equipment, electronics, automotive, and medical/lab equipment (requirements vary by program).

Injection molding gives you production-like material properties and surface finish, which is useful when validating fit, assembly, and end-use performance.

MUD (Master Unit Die) tooling is a modular tooling approach that can reduce cost and speed up tool build time for certain part geometries (project-dependent).

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Our experts help get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

We are ISO 9001:2015, ISO 13485, and AS9100D certified. Only the top shops that apply to become Suppliers make it through our qualification process.

All uploads are secure and confidential