STEP | STP | SLDPRT | STL | DXF | IPT | 3MF | 3DXML | PRT | SAT files

All uploads are secure and confidential.

Xometry’s Instant Quoting Engine is covered by U.S. Pat. Nos. 11,086,292, 11,347,201, 11,693,388, 11,698,623, 12,099,341, and 12,189,361. Other patents pending.

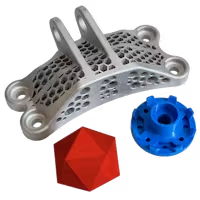

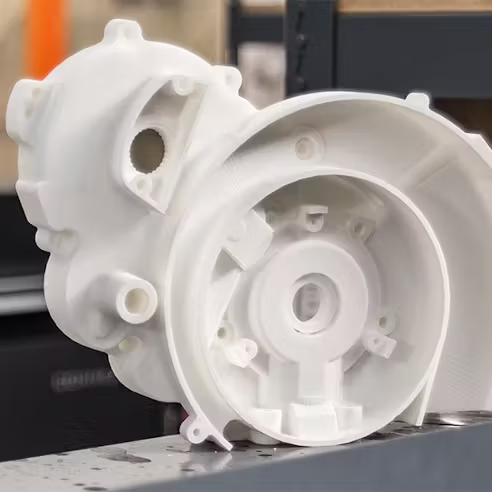

SLS 3D printing is a reliable way to make strong plastic parts without needing expensive molds. It is perfect for teams that need parts to work in the real world, want to change designs quickly, or need a small number of parts without waiting a long time for factory tools. We support you from early builds to ongoing small-batch production.

We help you check if your design is easy to make, suggest the best materials, and help you choose the right finish for the look and feel you need.

Bridge Production: Use this while waiting for permanent molds.

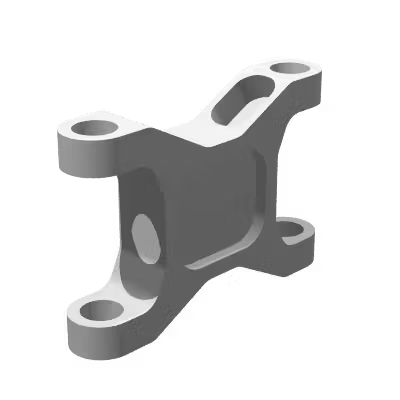

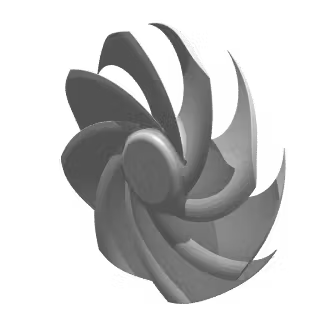

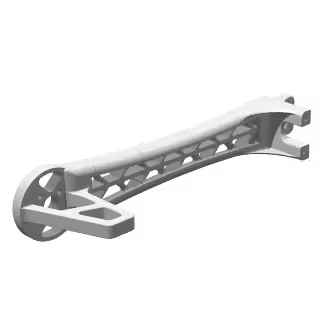

Complex Shapes: Create difficult designs without marks from support structures.

Durable Plastic: Uses strong nylon for parts that actually work.

Reliable Results: Get the same quality every time you order.

The material you choose depends on how much strength, stretch, heat, or wear the part will face

Nylon (PA11): Better for parts that need to bend or handle impacts.

Nylon (PA12): A good mix of strength, toughness, and size stability.

Glass-filled Nylon: Makes parts stiffer and helps them keep their shape better.

Specialty Options: We also offer options like ESD (static-safe) plastics after an expert check.

SLS parts are produced with a uniform matte surface. This option is ideal for functional parts and quick-turn builds.

Upload your CAD file and requirements. We’ll confirm material/finish options and provide a quote.

The speed and versatility of FDM lets engineers create physical snapshots of their designs.

An FDM machine can be used to create durable prototypes that withstand thermal, chemical, and mechanical stress.

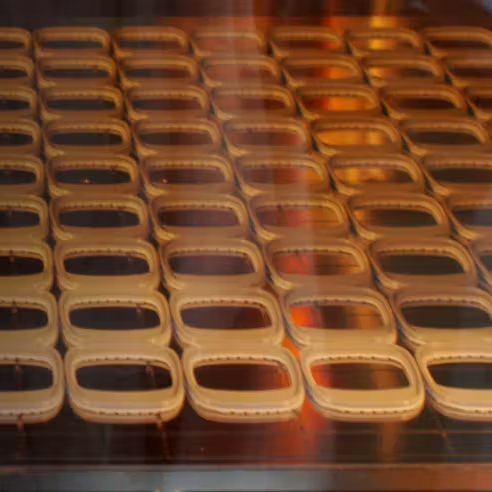

The high accuracy and consistency of SLS makes it an ideal way to build large quantities of discrete or customized parts.

Parts can typically be shipped in 3-4 days, allowing for faster design iterations and speed to market.

SLS is capable of producing end-use parts on-demand, increasing throughput.

Geometries can be built more easily due to the 3D printing process, adding complexity without additional cost.

SLS can make a single part or component as easily as dozens of production pieces.

We use the latest generation of SLS technologies to meet tolerances of +/- 0.010” or +/- 0.002” per inch, whichever is greater.

Good design choices improve surface quality, accuracy, and cost. If you’re early in design, LK Tools can provide feedback before production.

Our quick reference guides let you quickly compare different 3D printing processes!

Selective Laser Sintering (SLS) is an additive manufacturing process that uses a laser to fuse nylon powder layer-by-layer. After each layer is fused, a new layer of powder is applied until the part is complete.

Because the surrounding powder supports the part during printing, SLS can produce complex geometry without dedicated support structures. After printing, parts are cooled, cleaned, and can be finished (blasted, dyed, smoothed) depending on requirements.

SLS becomes especially valuable when you need repeatable part quality, stable material performance, and the flexibility to adjust designs without re-cutting tooling. It’s commonly used for bridge manufacturing while injection mold tooling is in progress, or for ongoing low-volume needs where tooling cost isn’t justified.

LK Tools can support production planning, batching strategy, and inspection requirements. Share your quantity forecast and quality expectations and we’ll recommend a practical production approach.

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

We are ISO 9001:2015, ISO 13485, and AS9100D certified. Only the top shops that apply to become Suppliers make it through our qualification process.

All uploads are secure and confidential