STEP | STP | SLDPRT | IPT | PRT | SAT files

All uploads are secure and confidential.

Xometry’s Instant Quoting Engine is covered by U.S. Pat. Nos. 11,086,292, 11,347,201, 11,693,388, 11,698,623, 12,099,341, and 12,189,361. Other patents pending.

Micro molding is a specialized form of plastic injection molding used to manufacture very small parts and micro-features with high precision. It’s commonly used when feature sizes are extremely small, part weight is minimal, and the design requires consistent repeatability at scale.

Micro molded components are often used in industries such as medical devices, electronics, automotive, aerospace, and micro-fluidics. Compared with conventional molding, micro molding typically requires tighter control of tooling, material flow, shot size, venting, and inspection strategy to maintain consistent results.

LK Tools supports micro molding projects where requirements and feasibility are confirmed during quoting. If micro molding isn’t the best fit for your design stage or quantity, we can also recommend micro-machining or high-resolution 3D printing options.

The micro molding process is similar to standard injection molding, but it demands more precise control and specialized tooling to achieve small feature accuracy and consistent filling.

Typical workflow:

Tooling fabrication

Micro molds and inserts are produced using precision methods such as EDM, micro-EDM, and micro-machining to achieve fine details and small tolerances.

Material preparation and process control

Thermoplastic resins (or elastomers, project-dependent) are prepared and processed with tight control over temperature, shot size, and injection pressure.

Injection, packing, and cooling

Material is injected into the micro mold at controlled rates and pressures. Cooling and ejection are engineered to reduce deformation and support consistent part release.

Ejection and inspection

Parts are removed and inspected. Because micro parts can be difficult to measure, inspection planning (critical features, sampling method, measurement equipment) should be defined early.

Micro molding projects may include different molding approaches depending on functional needs:

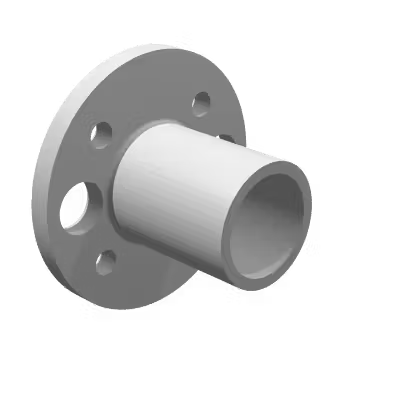

Insert micro molding places an insert (often metal) into the mold and then molds plastic around it to create a single integrated part. This can improve durability, create reliable attachment points, or integrate conductive/mechanical elements (project-dependent).

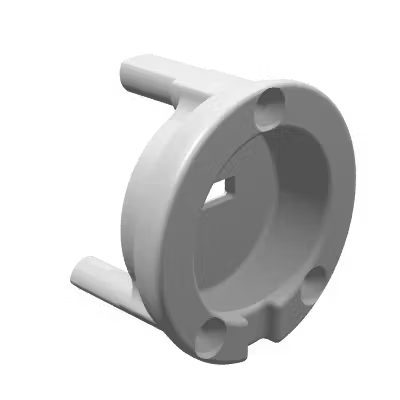

Micro overmolding combines two materials or two colors to create multi-material micro parts, such as small seals, gaskets, buttons, grips, or protective features (project-dependent).

Material selection is critical in micro molding because melt flow behavior, shrink characteristics, and part performance are highly sensitive at micro scale. Share your functional requirements (strength, flexibility, temperature, chemical exposure, regulatory needs) so we can recommend suitable resins.

Common micro molding material families (examples):

(Availability depends on part geometry and performance requirements.)

Polyethylene is one of the most commonly used thermoplastics in the world. Polyethylene is an FDA-compliant material, which makes it suitable for food and beverage applications. Additionally, it has great chemical and thermal resistance, as well as high tensile strength. Common applications of PE include: packaging, consumer goods, and textiles.

Polypropylene is another popular plastic used for components in a variety of industries and applications. Desirable properties of PP include: rigidity, wide operating temperature range, and chemical, corrosion, and fatigue resistance. Common applications of PP include: packaging, machinery components, textiles, and consumer goods.

Nylon is a popular thermoplastic lauded for its chemical resistance, strength, and dimensional stability across a wide temperature range. Nylon has many uses including: textiles, electrical housings, and mechanical components like bearings, bushings, and sprockets.

Polycarbonate is a thermoplastic known for its transparency, optical clarity, tensile and impact strength, recyclability, and chemical and fire resistance. These properties make polycarbonate great for electrical housings, switches, machine guards, and more.

Delrin® is DuPont’s trademarked polyoxymethylene (POM or acetal) resin. Delrin® is known for its strength, toughness, elasticity, rigidity, chemical and flame resistance, machinability, dimensional stability, and low friction coefficient. POM is used for mechanical components such as: gears, pulleys, and rollers.

PSU is a translucent thermoplastic known for its biocompatibility, food compatibility, good mechanical properties, and wide operating temperature range. PSU is commonly used in food preparation and medical industries due to its bio-friendliness.

PBT is a thermoplastic that has great dimensional stability, high strength, good chemical, UV, and thermal resistance, and low moisture absorption characteristics. PBT is often used in the automotive and electronics industries for automotive fenders, electrical enclosures, and power-tool housings.

Acrylic is a widely used thermoplastic due to its optical clarity and transparency, high tensile and impact strength, light weight, and durability. PMMA is often used as a substitute for glass and is commonly used in applications like: signage, windows, machine guards, and more.

PEEK is a special thermoplastic that is known for its wide operating temperature range up to 489 °F or 250 °C. Not only that, but it also has high strength, great chemical resistance, and high stiffness. PEEK is used in a variety of applications, from mechanical components like: bushings, bearings, and seals to fluidic components like valves and fittings, electrical housings, and connectors.

ULTEM® is a popular brand name for the thermoplastic PEI. PEI is known for its rigidity, high mechanical strength, and creep resistance over a broad range of temperatures. Additionally, PEI is a great electrical insulator, which makes it commonly used for applications like coils and fuses in electronics and interior trim pieces in aircraft.

LCPs are advanced polymer materials that maintain an ordered microstructure in both liquid and solid phases. The ordered microstructure results in exceptional mechanical strength and great temperature and flame resistance. Uses of LCP include: electrical connectors, catheters, surgical and dental instruments, and coatings on cookware.

Micro molding offers strong benefits when you need small parts at scale with consistent geometry:

Micro parts reduce system mass and enable compact assemblies—useful for portable electronics and medical components.

Micro molding supports miniature parts designed to fit into constrained spaces and dense assemblies.

Because parts and tools are smaller, cycle times and energy consumption may be lower than conventional molding for similar part counts.

Micro molding can achieve very precise features when tooling and process controls are engineered correctly. Share critical dimensions for feasibility review.

Many thermoplastics used in micro molding offer good chemical resistance, enabling use in harsh environments and fluid-contact applications.

Micro molded parts are used across many industries. Examples include:

Micro molding success depends on early alignment around design intent, critical features, and inspection strategy. LK Tools supports micro molding programs with:

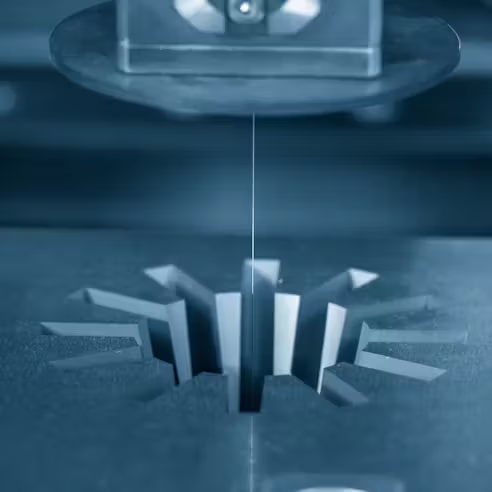

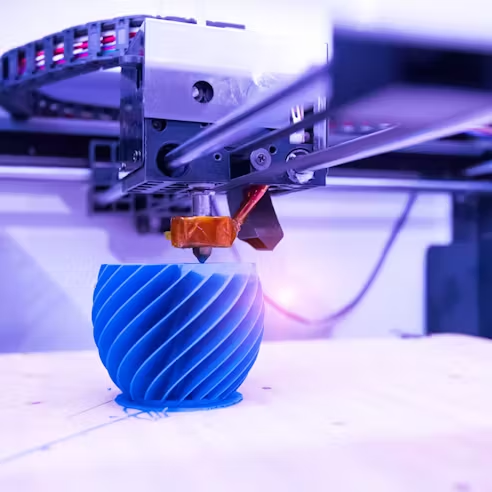

If micro molding isn’t the best match for your stage or geometry, consider:

Useful for early prototypes and complex micro geometry; may require post-processing and may be less economical at higher volumes.

Useful for tight tolerance features in metals or plastics; often slower and more expensive per part at volume.

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Get started with our easy-to-use platform and let our experts take care of managing the project from locating the right manufacturing partner to delivery logistics.

We are ISO 9001:2015, ISO 13485, and AS9100D certified. Only the top shops that apply to become Suppliers make it through our qualification process.

All uploads are secure and confidential