STEP | STP | SLDPRT | IPT | PRT | SAT files

All uploads are secure and confidential.

Xometry’s Instant Quoting Engine is covered by U.S. Pat. Nos. 11,086,292, 11,347,201, 11,693,388, 11,698,623, 12,099,341, and 12,189,361. Other patents pending.

Metal extrusion is commonly used to produce high volumes of material with a constant cross‑section. In extrusion, a heated (or sometimes room-temperature) billet is forced through a die opening under high pressure, producing a continuous profile that matches the die shape.

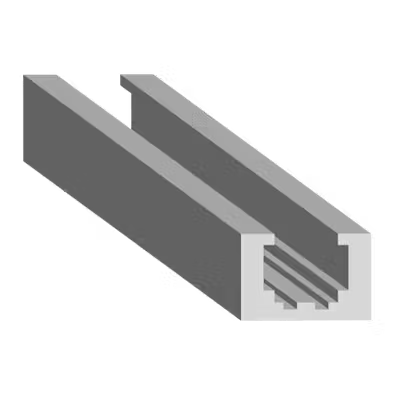

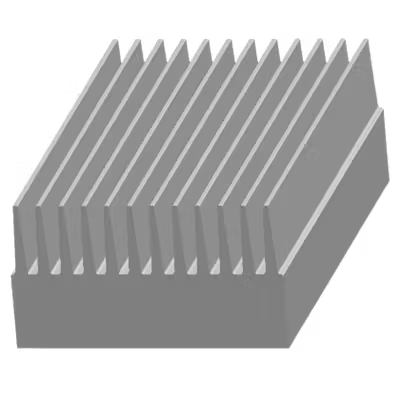

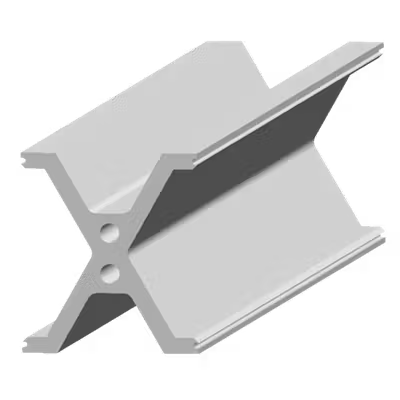

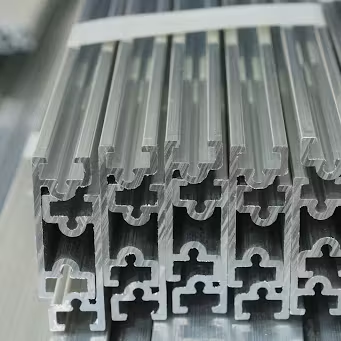

Extruded profiles can be simple—such as round or rectangular tubing, angles, and channels—or more complex shapes with internal hollows and external features, including T‑slot framing and heat sink profiles. After the profile exits the die, it is typically quenched or cooled, straightened, cut to length, and inspected. Secondary operations such as drilling, tapping, machining, and finishing can add features that are not part of the constant cross-section.

Extrusions may be solid or hollow. Hollow profiles often require specialized die design (such as multi-part tooling with mandrels) to form internal cavities. The overall size of the profile is limited by the press capacity, often described by the smallest circle that can fully enclose the profile (circumscribed circle).

Aluminum is the most common extruded metal due to its ductility, corrosion resistance, and broad finishing options. LK Tools can help you evaluate whether extrusion is the right fit and recommend a practical profile, alloy, temper, and post-processing plan.

Upload your CAD and drawings with key details: profile geometry, alloy/temper (if known), finish requirements, cut lengths, and expected volume. We’ll review feasibility and confirm any DFM recommendations.

We build an extrusion die and run initial samples for dimensional and functional review. Adjustments can be made based on measurement results and fit testing.

After approval, we proceed with repeat production and deliver parts according to your schedule. Reorders are supported once the profile is validated.

For ongoing extrusion programs, revision control helps keep supply consistent—especially if you expect multiple lengths, iterative profile tweaks, or scheduled releases. If you need tooling revision tracking or structured approvals, tell us during quoting so we can align the workflow.

Benefits (bullets):

(Only keep this section if you actually provide a formal tool-management workflow.)

LK Tools supports common extrusion methods and a wide variety of profile shapes. The best approach depends on alloy, profile complexity, and target tolerances.

In direct extrusion, a ram pushes the billet through a stationary die. This is one of the most common methods and supports a broad range of profile designs.

Considerations: friction between billet and container can increase heat and affect consistency; process controls and die design help manage this.

In indirect extrusion, the die moves toward the billet and the material flows opposite the ram direction. Because there is less relative motion between billet and container, friction is reduced.

Considerations: die size is constrained by the hollow ram; surface impurities can affect finish if not controlled.

These are temperature categories that can be applied to either primary method:

If you want to post-machine off-the-shelf profiles, LK Tools can also support machining and secondary processing.

Common profile families include:

Aluminum is widely used for extrusions due to its ductility, corrosion resistance, strength-to-weight ratio, and finishing options. Alloy choice affects strength, corrosion performance, machinability, and anodizing response.

If you have a specific alloy/temper requirement, include it in your RFQ. If not, share your application (structural vs cosmetic, indoor/outdoor, load/temperature exposure) and we can recommend options.

If you need stainless steel or another metal extrusion, include it as a custom request so we can review feasibility and sourcing.

(If you have a real “alloys comparison table,” paste it and I’ll rewrite it cleanly for LK Tools.)

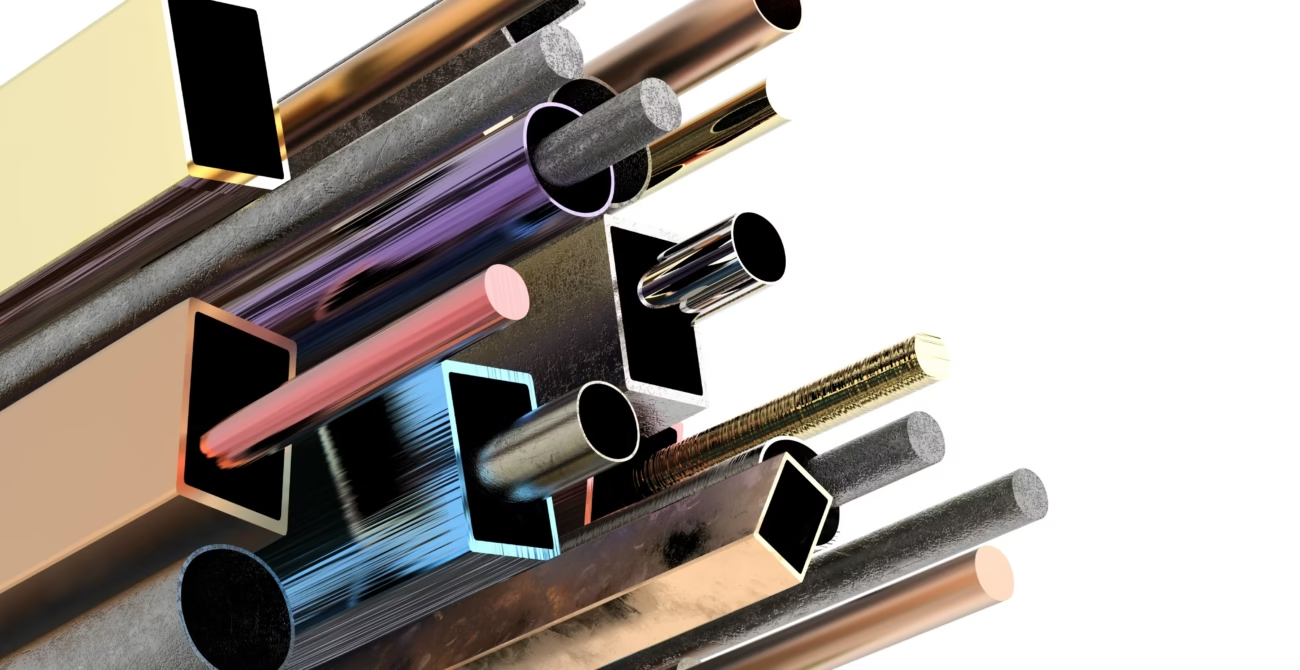

Array of metal extrusions with different finishes

Surface remains as produced. Roughness and visible grain lines can vary by alloy and process.

Type II improves corrosion resistance and offers color options; Type III is thicker and more wear resistant. (Anodizing is typically for aluminum; availability depends on alloy and requirements.)

Durable coating with many colors and textures; good for corrosion resistance and cosmetics.

Wide range of paint systems and color matching options (specify color requirements in notes or drawings).

Plating options vary by base material and requirements.

Helps corrosion resistance and paint adhesion while retaining electrical conductivity (commonly for aluminum).

Deburr and smooth edges via vibratory tumbling (best for smaller parts).

Request a specific finish if you don’t see what you need.

Metal extrusions are used across architecture, construction, transportation, industrial equipment, electronics, and more. Extrusion is often the most practical way to create continuous profiles at scale—especially when the cross-section includes channels, grooves, or thin-wall features.

Common applications:

Modern presses can produce consistent profiles when the die and process controls are validated.

Continuous production and efficient material usage make extrusion economical for repeat programs.

Tooling is often simpler than molding or casting tooling (project-dependent).

Extrusion supports grooves, channels, internal hollows, and profile features that remain constant along the length.

Die build, sampling, and setup create upfront cost before production.

The cross-section must remain constant; features like pockets, bosses, and countersinks require secondary machining.

Die build and iteration can take weeks depending on complexity and revision cycles.

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Get started with our easy-to-use platform and let our experts take care of managing the project from locating the right manufacturing partner to delivery logistics.

We are ISO 9001:2015, ISO 13485, and AS9100D certified. Only the top shops that apply to become suppliers make it through our qualification process.

All uploads are secure and confidential