Fast, accurate sheet cutting for prototypes and production parts. LK Tools supports laser cutting and sheet cutting workflows with engineering feedback, consistent quality, and scalable manufacturing support.

STEP | STP | SLDPRT | DXF | IPT | PRT | SAT files

All uploads are secure and confidential.

Xometry’s Instant Quoting Engine is covered by U.S. Pat. Nos. 11,086,292, 11,347,201, 11,693,388, 11,698,623, 12,099,341, and 12,189,361. Other patents pending.

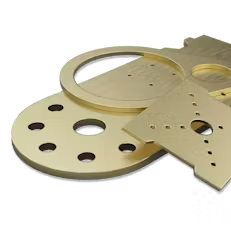

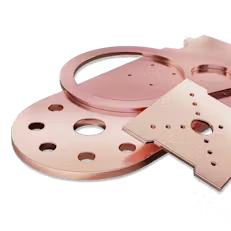

Sheet cutting is the process of producing flat parts from metal or other sheet materials by cutting profiles, holes, and internal features from a sheet. It’s commonly used for brackets, plates, panels, covers, gaskets, and flat patterns that will later be formed or assembled.

LK Tools supports sheet cutting for both one-off prototypes and repeat production batches. We can also review your design to confirm feature feasibility, recommend cost-saving adjustments, and advise on edge condition, tolerances, and finishing options.

This section provides general guidance for LK Tools sheet cutting services. Actual capability depends on material, thickness, feature size, and part geometry. If your design has critical dimensions, include a 2D drawing with tolerances or GD&T so we can confirm feasibility during quoting.

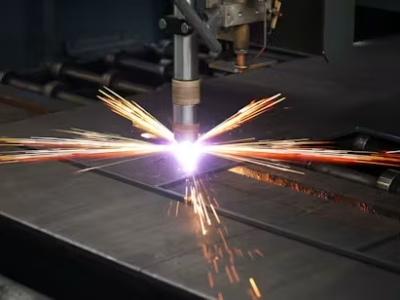

LK Tools coordinates sheet cutting through qualified manufacturing partners in the U.S. and globally. We convert CAD and drawing requirements into machine-ready toolpaths for laser cutting, waterjet cutting, or plasma cutting depending on material and design needs.

If your project requires deburring, marking, coating, or assembly steps, we can support a turnkey workflow. We regularly support industries such as aerospace, automotive, energy, industrial equipment, medical devices, robotics, and consumer products.

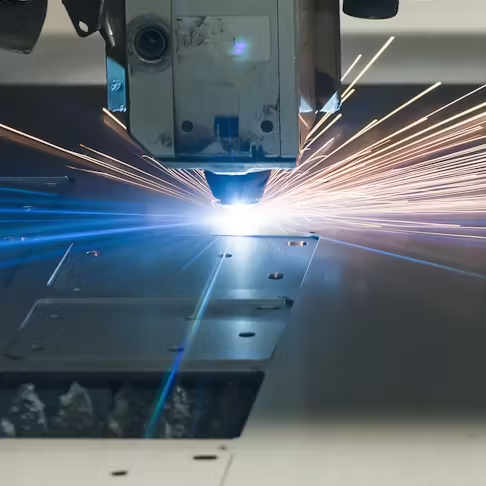

Laser cutting creates 2D profile cuts using a focused beam and thermal energy. It is typically fast and efficient for thin to moderate thickness materials and is commonly used for detailed profiles, tight cutouts, and part marking/engraving (where applicable).

Waterjet cutting uses high-pressure water (often with abrasive) to cut material without heat input. This can be advantageous for thicker metals or applications where heat-affected zones are a concern. Waterjet is also commonly used for cutting certain soft materials (like foams and gasket sheets) that may not be ideal for thermal cutting methods.

LK Tools will recommend the best method based on your material, thickness, geometry, and tolerance requirements.

Aluminum 6061-T6, 2024-T3, 5052-H32, 7075-T6, MIC6 (and other grades upon request)

Brass 260, Brass 353, Brass 464, Bearing Bronze 932, Bronze 220, Bronze 510 (spring), Silicon Bronze 655

Copper 101, Copper 110

17-4 PH, 17-7, 301, 304, 316, 410, 430, 440C (additional grades available by request)

ABS, Acetal (POM/Delrin), PETG, PC, PP, PTFE, PVC, UHMW (availability depends on thickness and application)

Clear and colored acrylic (Plexiglass)

EVA Foam, Polyurethane Foam (PU), Silicone Foam

Cherry, Hardboard, MDF, Poplar, Red Oak, Wood Laminate (Plywood)

Carbon Fiber, Garolite G-10, Garolite G-11, Garolite LE (Phenolic)

EVA Foam, Polyurethane Foam (PU), Silicone Foam

Titanium Grade 2 and 5, Nickel Alloy

Buna-N Rubber Blends, EPDM, Silicone Rubber, Paper Fiber, PTFE

Parts will be separated, the tab will be ground off, and all burrs will be removed. Additionally, parts are cleaned to remove discoloration, surface debris, manufacturer markings, and scratches.

Parts will be separated from each other, and the source sheet and any vestigial tabs will be ground off. The area where tabs are removed may have a slightly different texture or appearance than the rest of the part.

Reduce costs by receiving the parts tabbed together on the source sheet, to each other, or a support structure. You are then responsible for separating the parts from the sheet. Laser and waterjet cut parts may have fine burrs after cutting.

Parts are finished in a blasting cabinet with a high-pressure stream of fine glass beads, typically using 80-grit media applied between 70-100 psi. This gives the surface of the parts a uniform matte or satin-like cosmetic appearance.

Parts are finished in a vibratory or rotary tumbler with tumbling media. This provides an even stippled finish over the face of the entire part. It also tends to round sharp corners and edges.

A standard finish is available for all materials. No additional post-processing is performed, leaving the surface as-is after your choice of de-tabbing and deburring is performed. Plastics and cosmetically finished products may have an overwrap left on the faces for production. It is common for pre-polished, brushed, or textured materials to have only one side cosmetically finished.

Metal parts are sanded by hand, abrasive belt sander, or timesaver, in the direction of the grain to create a uniform finish. This is also called linear finishing.

Metal parts are sanded by hand, orbital sander, or timesaver, in a random pattern or swirl to create a uniform finish. This is also called a random swirl finish.

Like our other services, Xometry can offer turnkey finishing services like anodizing, chem-film, metal plating, powder coating, heat treating, passivation, and even multiple custom finishes.

We’ve compiled practical tips to help you choose between laser and waterjet cutting, prepare DXF files correctly, and design parts that cut cleanly and assemble reliably. The guide covers common design rules, kerf considerations, feature sizing, and finishing options for sheet cut parts.

We accept STEP/STP and DXF as common formats. Include a 2D drawing for critical dimensions, tolerances, and notes.

Yes—outside profiles, internal cutouts, and hole patterns are supported. Feature limits depend on thickness and method.

Kerf is the width of material removed by the cutting process. Kerf depends on the method (laser/waterjet), material, and thickness, and is considered during programming to achieve the intended size.

Many sheet materials have a grain direction from rolling or manufacturing. Grain direction can affect forming behavior and cosmetic appearance.

Edge appearance varies by method and material. Deburring and edge conditioning are available if smoother edges are required.

Hole quality depends on diameter, thickness, and method. For tight requirements, we may recommend secondary operations.

Threads are typically added using secondary operations (tapping) or hardware insertion (PEM) depending on the part.

Provide a drawing note indicating engraving location, content, and depth/visibility requirement (if applicable).

Project-dependent. Share thickness and material requirements and we’ll confirm feasibility and handling approach.

Waterjet-cut parts may retain moisture immediately after cutting. Drying/cleaning steps can be specified if needed.

Free shipping available for domestic sheet cutting orders

Choose from thousands of possible combinations of sheet materials, finishes, tolerances, markings, and certifications for your order.

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

We are ISO 9001:2015, ISO 13485, and AS9100D certified. Only the top shops that apply to become Suppliers make it through our qualification process.

All uploads are secure and confidential