LK Tools supports custom weldments to help teams complete complex assemblies efficiently and reliably. We can coordinate material sourcing, cutting/prep, welding, secondary operations, finishing, and inspection—so you receive assemblies ready for integration.

To quote accurately, weldments require more input than single-part RFQs. The guidance below shows the best way to request weldment services so we can confirm scope, tolerances, and inspection expectations early.

Follow these steps to help us quote and manufacture your assembly as smoothly as possible. If anything is unclear, include what you have and we’ll follow up to confirm missing details.

1) Upload your 3D CAD files

2) Specify welding and build requirements

Include notes for:

3) Quality / documentation requirements (if applicable)

If your program needs special documentation, traceability, or inspection levels, call that out upfront so we can align the process plan.

4) Request a manual quote for complex assemblies

For assemblies with many components, tight tolerances, or specialized inspection, a manual quote is often the most accurate path.

Need help?

Use your website contact form or include your questions in the RFQ notes and our team will respond.

Different welding processes fit different materials, thicknesses, and cosmetic requirements. LK Tools can support multiple welding methods depending on project needs and supplier capability.

TIG Welding (GTAW)

Clean, controlled welds often selected for cosmetic parts, thin materials, and precision assemblies.

MIG Welding (GMAW)

Efficient and widely used for general fabrication and production weldments.

FCAW (Flux-Cored Arc Welding)

High deposition and deep penetration for structural and heavier-duty work (project-dependent).

Stick Welding (SMAW)

Versatile process often used for structural work and repairs (project-dependent).

Submerged Arc Welding (SAW)

Well-suited for long seams and thick sections in certain fabrication environments (project-dependent).

Spot Welding (Resistance Spot Welding)

Common for sheet metal assemblies where speed and repeatability matter (project-dependent).

If you don’t see the welding process you need, include your requirements and we’ll review options.

Good weldments start with good design and clear callouts. Below are practical DFM tips:

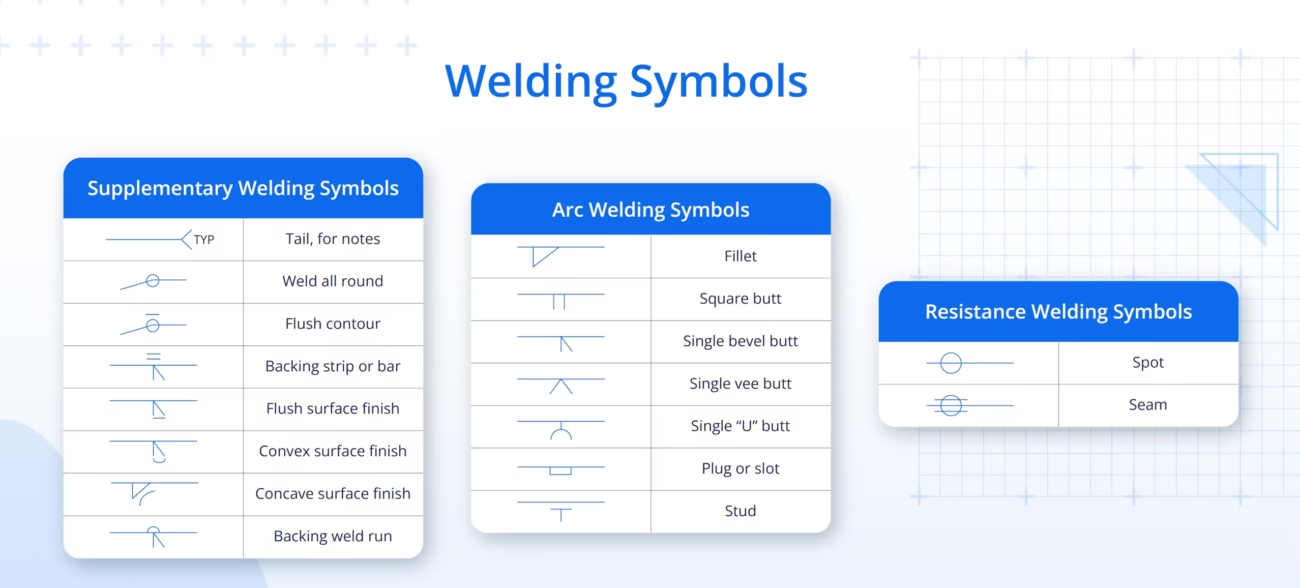

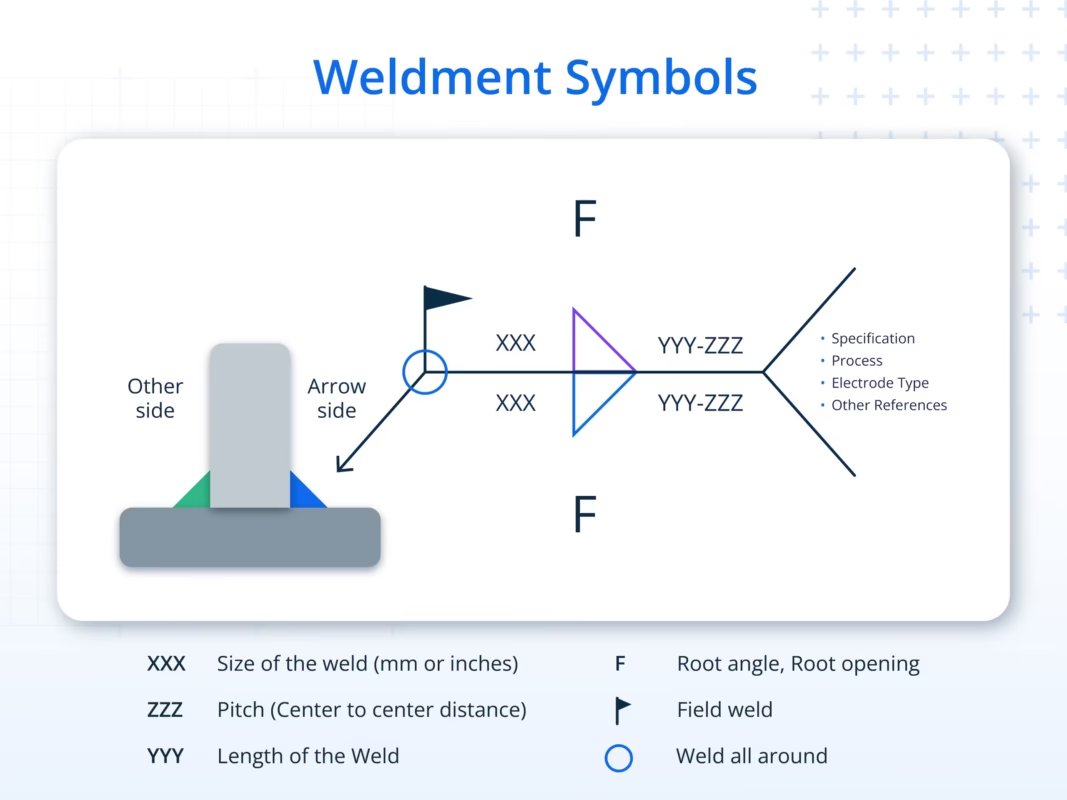

Use Standard Weld Symbols: Include weld symbols and notes on 2D drawings to avoid ambiguity and reduce rework.

Mitigate Distortion in Long Seam Welds:

Intermittent (stitch) welding, balanced weld sequencing, and proper fixturing can reduce warpage—especially on thin wall structures.

Avoid Welding Dissimilar Metals: Mixing alloys can create joining issues and corrosion risks. When dissimilar metals are required, call it out so we can review feasibility.

Account for Heat-Affected Zones: Expect local distortion near welds and plan datum strategy accordingly—especially for tight-tolerance assemblies.

Define appropriate gaps: Too small a gap can cause lack of fusion; too large can increase burn-through risk. Call out root opening and prep where needed.

LK Tools can help simplify weldment sourcing and manufacturing by coordinating the workflow end-to-end.

Key advantages:

Additional benefits:

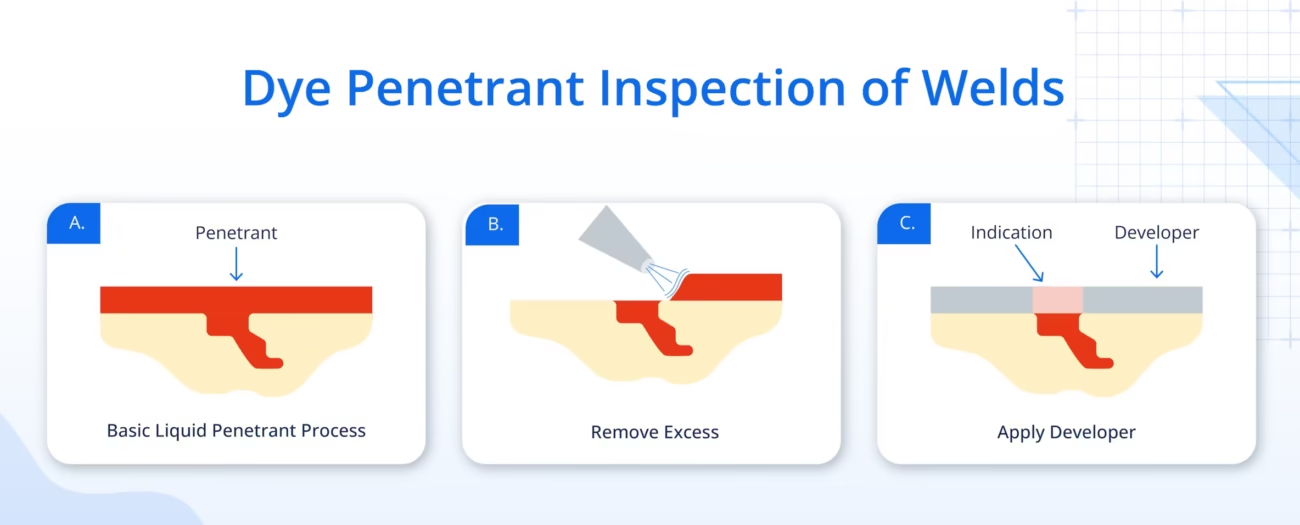

Inspection needs vary widely by weldment type. We can support inspection planning and documentation options based on your requirements.

Common inspection options (project-dependent):

If you need inspection records, sampling plans, traceability, or specific acceptance criteria, include that in your RFQ notes.

(Remove the “100% quality control” and “certifications offered” list unless you can verify those certifications for LK Tools.)

Certifications Offered:

Each certification reflects our commitment to quality and precision, giving you confidence in every weld.

Custom weldments are used across many industries and applications, including:

Whether you need a single prototype weldment or repeat production assemblies, we can review your requirements and recommend a practical manufacturing plan.

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Get started with our easy-to-use platform and let our experts take care of managing the project from locating the right manufacturing partner to delivery logistics.

We are ISO 9001:2015, ISO 13485, IATF 16949:2016 and AS9100D certified. Only the top shops that apply to become suppliers make it through our qualification process.

All uploads are secure and confidential