Industrial metal additive manufacturing for prototypes and production parts, including DMLS/SLM and binder jetting. Choose metal 3D printing when you need complex geometry, consolidated assemblies, or rapid iteration.

STEP | STP | SLDPRT | STL | DXF | IPT | 3MF | 3DXML | PRT | SAT files

All uploads are secure and confidential.

Xometry’s Instant Quoting Engine is covered by U.S. Pat. Nos. 11,086,292, 11,347,201, 11,693,388, 11,698,623, 12,099,341, and 12,189,361. Other patents pending.

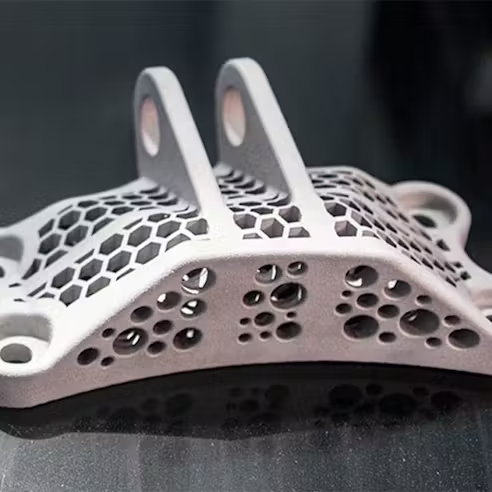

Metal 3D printing is an additive manufacturing process that builds metal parts layer-by-layer from powder. It’s often selected as an alternative to CNC machining or casting because it can produce metal-strength parts while enabling complex features that are difficult or impossible to machine—such as internal channels, lattice structures, conformal cooling paths, and topology-optimized shapes.

Metal additive can also reduce assembly complexity by combining multiple components into a single printed part. This can improve strength and reliability by reducing fasteners, joints, and leak paths (application-dependent).

Metal additive manufacturing is useful when you need high-performance metal parts and design freedom in the same workflow.

Common advantages include:

Note: Mechanical properties, surface finish, and dimensional accuracy depend on process, orientation, supports, post-processing, and alloy.

LK Tools supports both DMLS (laser powder bed fusion) and metal binder jetting. These processes differ in how parts are formed, what alloys are available, achievable density, surface finish, cost, and post-processing needs.

Choose based on:

DMLS/SLM uses a laser to selectively fuse metal powder into near-net-shape parts. It is often selected for parts that need higher density and stronger mechanical performance, and it can support complex internal features.

Typical characteristics:

Binder jetting prints a “green” part by depositing a binder into a powder bed layer by layer. The part is then cured and densified through sintering and/or infiltration depending on alloy system.

Typical characteristics:

For designs with tight fits, plan for dimensional change and include critical dimensions on a drawing so scaling and post-processing can be evaluated.

Metal additive manufacturing is frequently used for:

Because metal 3D printing supports complex geometry, it’s often chosen for parts that benefit from weight reduction, internal passages, or consolidated assemblies.

Free shipping available for domestic 3D printing orders ; learn more!

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

We are ISO 9001:2015, ISO 13485, and AS9100D certified. Only the top shops that apply to become Suppliers make it through our qualification process.

All uploads are secure and confidential