STEP | STP | SLDPRT | IPT | PRT | SAT files

All uploads are secure and confidential.

Xometry’s Instant Quoting Engine is covered by U.S. Pat. Nos. 11,086,292, 11,347,201, 11,693,388, 11,698,623, 12,099,341, and 12,189,361. Other patents pending.

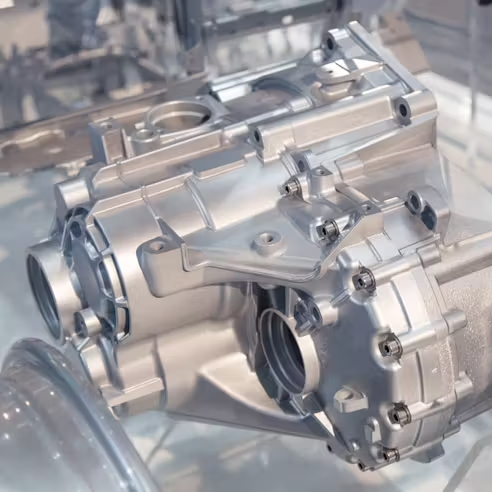

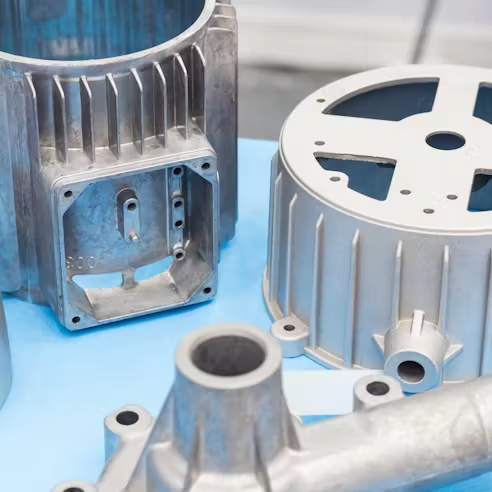

Die casting is widely used to produce medium-to-high volumes of metal parts with complex geometry and consistent repeatability. In die casting, molten metal is injected into a precision die (mold) under pressure, where it solidifies into the final shape before ejection.

Like injection molding, die casting requires dedicated tooling. Once the die is built and validated, the process can deliver excellent part-to-part consistency and favorable unit cost at volume. Secondary operations may still be used for critical features—post-machining is common for tight functional tolerances, precision holes, and mating surfaces. Die cast parts can also be finished in many of the same ways as machined metal parts, depending on alloy and cosmetic requirements.

Die casting is most commonly applied to lower-melting-point alloys such as aluminum and zinc. Different machine types and process variations (hot chamber, cold chamber, and specialized methods) are selected based on material, geometry, and quality requirements.

LK Tools reviews each die casting project to confirm manufacturability, tolerance approach, finishing needs, and production readiness before tooling begins.

Upload your CAD and drawings with material, finish, and volume requirements. We review the design and provide manufacturability feedback (DFM) before tooling starts.

After the die is built, first samples are produced for approval. We confirm critical dimensions, cosmetic expectations, and any required secondary operations.

Once samples are approved, we move into production and deliver parts according to your schedule. Repeat orders can be supported once the process is validated.

LK Tools can support common die casting approaches depending on alloy and part requirements. Our offering focuses on the two primary die casting process families: hot chamber and cold chamber casting.

Hot chamber die casting (sometimes called gooseneck casting) is commonly used for lower-melting-point alloys such as zinc and certain magnesium alloys. The injection system is integrated with the molten metal reservoir, enabling fast cycles and high throughput.

This approach is often chosen when you need:

Cold chamber die casting uses molten metal that is melted in a separate furnace and transferred into the shot chamber before injection. This process is typically used for higher-melting-point alloys—most commonly aluminum.

Cold chamber die casting is often chosen when:

Several alloys are commonly used in die casting. Material selection depends on strength, weight, corrosion resistance, thermal performance, cosmetic needs, and cost targets. Share your performance requirements and environment of use, and we’ll recommend suitable alloys.

Aluminum is one of the most common die casting materials due to its favorable strength-to-weight ratio and corrosion resistance. Aluminum die cast parts are widely used in automotive, industrial equipment, lighting, and many structural housings.

Common reasons teams choose aluminum die casting:

Common aluminum casting alloys (examples):

Zinc is valued for excellent castability, strong detail reproduction, and the ability to create thin walls and fine features (design-dependent). Zinc alloys often cast efficiently and can support attractive surface finishes, plating, and cosmetic requirements.

Common reasons teams choose zinc die casting:

Common zinc casting alloys (examples):

Zinc and aluminum zinc parts can be left as-cast and retain reasonable corrosion resistance. Aluminum parts must be coated to achieve corrosion resistance. Cast parts are typically broken away from the casting sprue, leaving rough marks at the gate locations. Most castings will also have visible marks left by the ejector pins. The surface finish for as-cast zinc alloys is commonly 16-64 microinch Ra.

The part surface is left with a smooth, matte appearance.

Aluminum is typically anodized. Type II anodizing creates a corrosion-resistant oxide finish. Although suppliers can anodize parts in different colors, the surface of a die cast part does not facilitate a cosmetic finish with anodizing. Type III is a thicker finish and creates a wear-resistant layer in addition to the corrosion resistance seen with Type II. Anodized coatings are not electrically conductive.

All die cast parts can be powder coated. This is a process where powdered paint is electrostatically sprayed onto a part, then baked in an oven. Powder coating creates a strong, wear- and corrosion-resistant layer that is more durable than standard wet painting methods. A wide variety of colors are available to create the desired aesthetic.

All die cast parts can be wet painted in a wide variety of paint formulations and colors.

Die cast parts can be plated with electroless nickel, nickel, brass, tin, chrome, chromate, Teflon, silver and gold.

Suppliers can apply a chromate conversion coat to protect aluminum from corrosion and improve the adhesion of paints and primers. Chemical film conversion coatings are electrically conductive.

Die cast materials are subjected to vibratory media tumbling to remove sharp edged and smooth surfaces.

Don’t see the finish you need? Submit an RFQ and our partner shops will look into a finishing process for you.

Die casting is a strong fit for parts that are small-to-medium in size, require repeatability, and benefit from high-volume economics. It’s often selected for housings, brackets, covers, and components where shape complexity would be costly to machine at scale.

Common die casting applications include:

Die casting can produce thin walls and complex features with good repeatability.

Die cast metal parts are generally stronger and more temperature-resistant than molded plastics for comparable geometries.

Achievable tolerances depend on alloy, geometry, die design, and secondary operations. Tight functional features are often finished via machining.

A variety of coatings and cosmetic finishes are available to improve corrosion resistance and appearance.

Dies require significant upfront investment and maintenance compared to no-tooling methods.

For small batch quantities, CNC machining or other processes may be more economical.

Tool design, die build, sampling, and validation can take multiple weeks before full production begins.

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Get started with our easy-to-use platform and let our experts take care of managing the project from locating the right manufacturing partner to delivery logistics.

We are ISO 9001:2015, ISO 13485, and AS9100D certified. Only the top shops that apply to become Suppliers make it through our qualification process.

For tooling-based programs, revision control and clear status updates help keep production consistent. If your program requires tool revision tracking, sampling history, or structured release management, tell us during quoting so we can align the workflow.

Benefits (bullets):

(Only keep this section if you actually provide a tool-management workflow.)

All uploads are secure and confidential