Precision CNC milled parts for prototypes, validation builds, and low-volume production. LK Tools supports engineers and purchasing teams with dependable quality, clear communication, and scalable manufacturing support.

STEP | STP | SLDPRT | IPT | PRT | SAT files

All uploads are secure and confidential.

Xometry’s Instant Quoting Engine is covered by U.S. Pat. Nos. 11,086,292, 11,347,201, 11,693,388, 11,698,623, 12,099,341, and 12,189,361. Other patents pending.

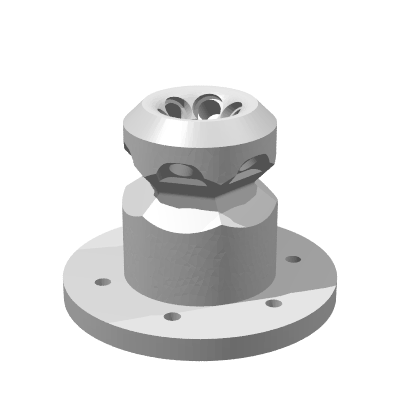

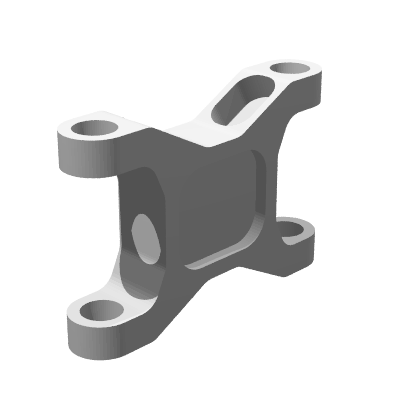

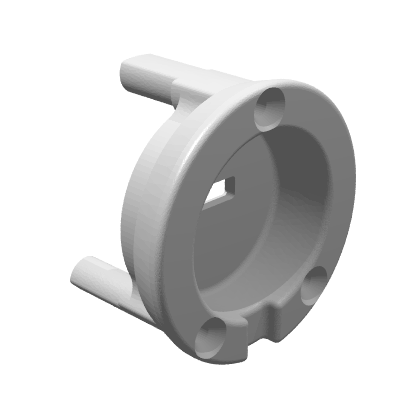

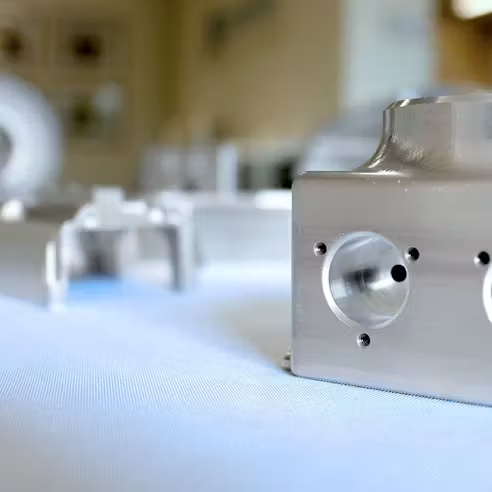

CNC milling is ideal when your design needs accurate features, flatness control, clean pockets, and reliable mating surfaces. LK Tools provides milling support for a wide range of components—from simple brackets to complex housings and precision assemblies.

Whether you need a single prototype or repeatable small-batch production, our team helps select the right material, tool strategy, and finishing options to meet your performance and cosmetic requirements. If cost or lead time is critical, we can recommend design adjustments that reduce machining time while protecting function.

LK Tools machines a broad selection of metals and plastics. If you have a preferred grade or spec requirement, include it in your RFQ and we’ll confirm availability and lead time.

Need a specific brand, certification, or customer-supplied stock? We can support special sourcing and traceability requirements on request. Share your material standard (ASTM/AMS/ISO), required certs (e.g., mill cert/CoC), and any restrictions, and we’ll align the machining plan accordingly.

The finish option with the quickest turnaround. Parts are left with visible tool marks and potentially sharp edges and burrs, which can be removed upon request. Surface finish is comparable to 125 uin Ra finish.

The part surface is media blasted, typically using glass bead, to produce a smooth, matte appearance.

Type II creates a corrosion-resistant finish. Parts can be anodized in different colors—clear, black, red, and gold are most common—and is usually associated with aluminum. Type III is thicker and creates a wear-resistant layer in addition to the corrosion resistance seen with Type II.

This is a process where powdered paint is sprayed onto a part which is then baked in an oven. This creates a strong, wear- and corrosion-resistant layer that is more durable than standard painting methods. A wide variety of colors are available to create the desired aesthetic.

Don’t see the finish you need? Submit an RFQ and we’ll look into a finishing process for you.

Upload your CAD files and requirements—our engineers will confirm feasibility, materials, and finishing options.

Because CNC can be applied to virtually any material, it is perfect for rapid tooling, i.e., creating fixtures or molds.

The range of materials available, low CNC machining costs per unit, and speed of production makes CNC a great option for prototyping.

High-quality finish, vast material options and precise tolerances have made CNC a favorable technology for end-use parts.

Using the latest CNC machining capabilities, Xometry produces highly accurate, quick turn parts in as fast as 1 day. We also instantly quote CNC machined parts, cutting days off of your RFQ process.

Offers high-precision tolerances, including sub +/- 0.001″ tolerances. We are the experts in making parts that are truly custom and ready to use.

CNC machining processes are perfect for prototyping and production CNC parts. Xometry’s massive scale can help you scale up from testing phase to production runs of 100,000 parts of more.

Choose from over 50 metal and plastic materials. CNC Machines offer a wide variety of certified materials.

Achievable tolerance depends on part geometry, material, feature type, and inspection method. For critical dimensions, include a 2D drawing with GD&T or explicit tolerances. LK Tools can support inspection requirements such as CMM reports and first-article documentation upon request.

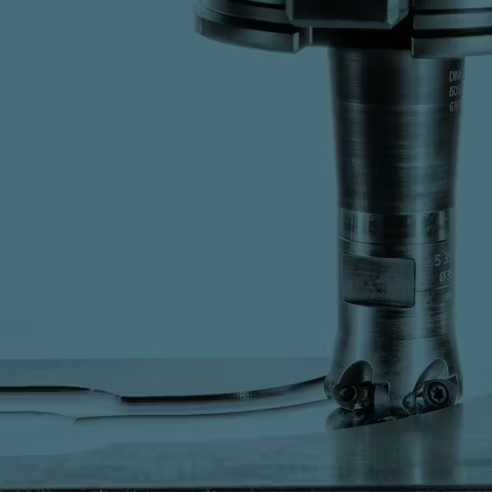

CNC milling is a subtractive manufacturing process where rotating cutting tools remove material to create precise shapes, pockets, slots, and surfaces. It’s commonly used for parts that require accurate alignment, flat surfaces, and complex geometry.

Milling is well-suited to aluminum, steels, stainless steel, brass, copper, and many engineering plastics. Because toolpaths are digitally controlled, CNC milling delivers repeatable results—making it a reliable choice from prototype through production.

The most widely used type of CNC milling machine. The full use of the X, Y, and Z directions makes a 3 Axis CNC mill useful for a wide variety of work.

This type of router allows the machine to rotate on a vertical axis, moving the workpiece to introduce more continuous machining.

These machines have three traditional axes as well as two additional rotary axes. A 5-axis CNC router is, therefore, able to machine 5 sides of a workpiece at in one machine without having to remove the workpiece and reset. The workpiece rotates, and the spindle head is able to also move around the piece. These are larger and more expensive.

CNC milling is a practical option when you need dependable mechanical properties and dimensional control. Compared with some alternatives, milling allows you to use real production materials early in development and iterate designs without waiting for tooling changes.

If your project later requires higher volumes, LK Tools can help you evaluate when to transition to die casting, extrusion, or injection molding—while using CNC milling as a bridge during validation and pilot production.

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

We are ISO 9001:2015, ISO 13485, and AS9100D certified. Only the top shops that apply to become Suppliers make it through our qualification process.

All uploads are secure and confidential