Precision CNC-turned parts for prototypes and low-volume production. LK Tools supports round and rotational components with reliable accuracy, clean surface finishes, and responsive engineering support.

STEP | STP | SLDPRT | IPT | PRT | SAT files

All uploads are secure and confidential.

Xometry’s Instant Quoting Engine is covered by U.S. Pat. Nos. 11,086,292, 11,347,201, 11,693,388, 11,698,623, 12,099,341, and 12,189,361. Other patents pending.

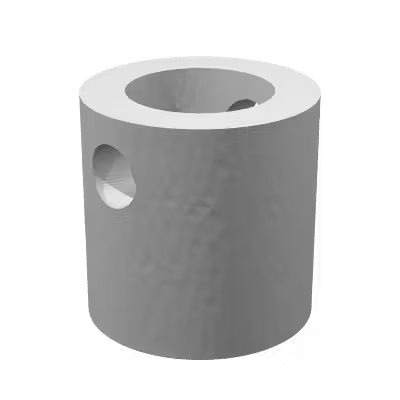

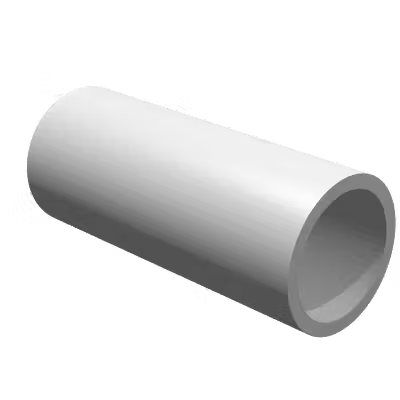

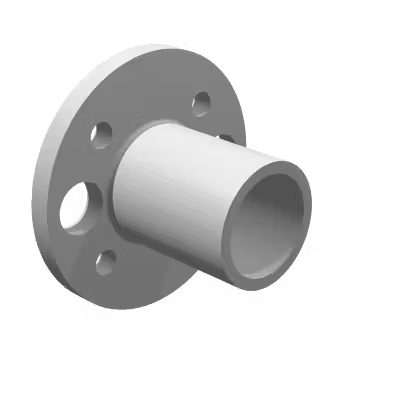

CNC turning is a machining process optimized for parts with cylindrical or rotational geometry. finish control. It’s commonly used for shafts, bushings, spacers, threaded components, and parts that need accurate diameters, grooves, and internal bores.

LK Tools supports both prototype and low-volume production turning, including secondary operations such as drilling, tapping, knurling, and finishing. If your design has critical fit features, we can review your drawings and recommend a machining strategy that protects tolerances and reduces cost.

LK Tools provides CNC turning support for fast prototypes, engineering validation builds, and repeat low-volume production. If your part needs both turning and milling features, we can recommend the most efficient route—such as secondary milling operations or turn-mill strategies—based on geometry and tolerance requirements.

We machine a broad range of materials for turning applications. Share your preferred grade, specification, or performance requirement and we’ll confirm availability during quoting.

If your project requires a specific material brand, certification programs with strict requirements, LK Tools can support special material sourcing and documentation. Share your material standard, certification needs (CoC / mill cert), and any compliance requirements, and we’ll align the supply and machining plan accordingly.

The finish option with the quickest turnaround. Parts are left with visible tool marks and potentially sharp edges and burrs, which can be removed upon request. Surface finish is comparable to 125 uin Ra finish.

The part surface is left with a smooth, matte appearance.

Type II creates a corrosion-resistant finish. Parts can be anodized in different colors—clear, black, red, and gold are most common—and is usually associated with aluminum.Type III is thicker and creates a wear-resistant layer in addition to the corrosion resistance seen with Type II.

This is a process where powdered paint is sprayed onto a part which is then baked in an oven. This creates a strong, wear- and corrosion-resistant layer that is more durable than standard painting methods. A wide variety of colors are available to create the desired aesthetic.

Don’t see the finish you need? Submit an RFQ and we’ll look into a finishing process for process for your custom lathe work.

Upload your CAD and requirements—our team will confirm feasibility, material options, and finishing choices.

Because CNC can be applied to virtually any material, it is perfect for rapid tooling, i.e., creating fixtures or molds.

The range of materials available, low cost per unit, and speed of production makes CNC a great option for prototyping.

High-quality finish, vast material options, and precise tolerances have made CNC lathe turning a favorable technology for serial production parts.

Using the latest CNC machines, Xometry produces highly accurate, quick turn parts in as fast as 1 day.

Select from a variety of finishes on solid metal and plastic parts, built to precise design specifications.

Choose from over 50 metal and plastic materials. CNC Machining offers a wide variety of certified materials.

Offers high-precision tolerances ranging from +/-0.001″ – 0.005″, depending on customer specs.

CNC Machining is perfect for production of 1-10,000 CNC machined parts.

General tolerances depend on part geometry, material, and inspection requirements. For critical features, include a 2Dances or GD&T. LK Tools can support inspection reports (e.g., CMM) and first-article documentation upon request.

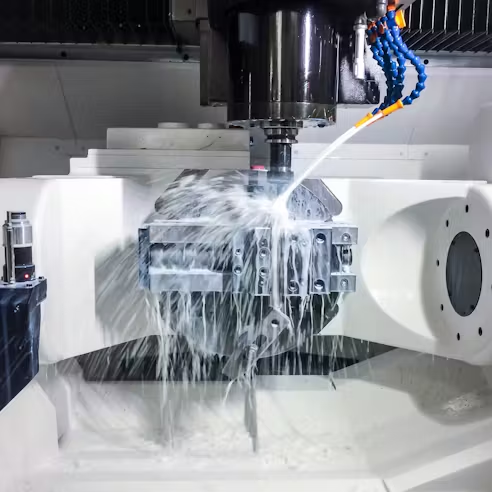

CNC turning is a subtractive process used to create parts by rotating a workpiece while cutting tools remove material. This approach is especially effective for cylindrical shapes and concentric features.

During turning, the part is held in a chuck or collet and rotated at controlled speed while the tool removes material. Many programs also include secondary features—such as cross-holes, flats, or milled pockets—using live tooling or follow-up milling operations, depending on design needs.

Types Of CNC Lathes

Subheading: Benefits of CNC Turning

CNC turning offers efficient production for cylindrical parts, dependable repeatability, and strong control of concentric features—making it a practical choice for both prototypes and ongoing low-volume supply.

All uploads are secure and confidential