Fast, accurate CNC routing for plastics, composites, and sheet materials. LK Tools supports prototypes and low-volume production with consistent cut quality, practical engineering guidance, and scalable manufacturing support.

STEP | STP | SLDPRT | IPT | PRT | SAT files

All uploads are secure and confidential.

Xometry’s Instant Quoting Engine is covered by U.S. Pat. Nos. 11,086,292, 11,347,201, 11,693,388, 11,698,623, 12,099,341, and 12,189,361. Other patents pending.

CNC routing is an efficient way to cut and machine sheet-based parts with clean edges and repeatable geometry. It’s commonly used for plastic panels, enclosures, brackets, fixtures, insulation components, and composite parts where profile accuracy and consistent cut quality matter.

LK Tools can support routing projects from early prototypes through repeat low-volume runs. If your part has tight fit requirements or needs a specific edge quality, share those details in your RFQ—our engineers can recommend tooling, cut strategy, and finishing options.

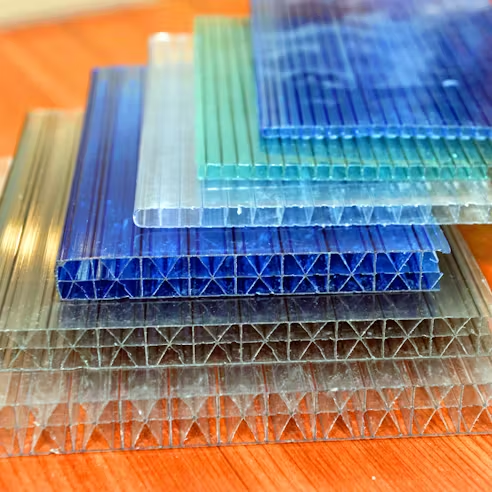

Our CNC routing services cover a wide range of materials, including MDF (medium-density fiberboard), plywood, acrylic, polyurethane foam, and polyethylene sheet, as well as softer metals like brass, aluminum, and occasionally steel.

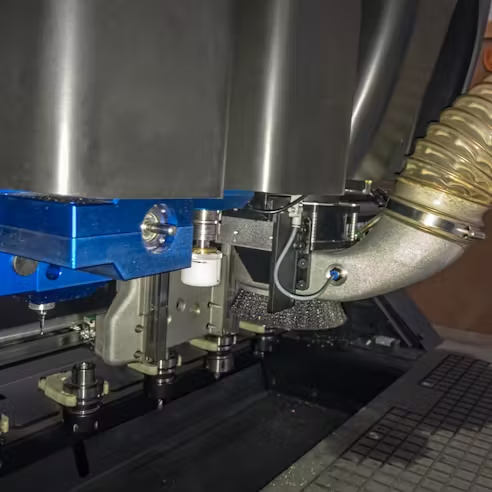

CNC routing is a subtractive manufacturing process that uses a high-speed spindle and cutting tools to cut profiles, pockets, slots, and holes—most often in sheet materials. Unlike typical CNC milling (often used for thicker blocks), routing is optimized for panels and flat stock, making it a practical solution for larger parts and faster throughput.

Depending on geometry and material, routing can include drilling, countersinking, engraving, and pocketing. LK Tools can also advise on best practices for tabs, fixturing, edge protection, and part nesting to control cost and lead time.

When fixturing and material stability are controlled, CNC routing can achieve consistent dimensions for profiles, hole patterns, and assembly features. Share your critical dimensions and we’ll confirm feasibility during quoting.

When fixturing and material stability are controlled, CNC routing can achieve consistent dimensions for profiles, hole patterns, and assembly features. Share your critical dimensions and we’ll confirm feasibility during quoting.

Routing supports fast design changes—perfect for prototypes and iterative development without tooling changes.

Once your program is dialed in, routing provides repeatable part geometry for ongoing low-volume or batch production.

Profiles, pockets, engraved details, and cutouts are straightforward—especially for panel parts and enclosures.

CNC routers are compatible with a wide range of materials, including: soft metals, wood, plastics, and composites. Below is a list of some of the most common materials used in CNC routing:

The best routing outcome comes from matching tool selection and cutting parameters to the material and part geometry. Factors like wall thickness, small internal radii, deep pockets, and high cosmetic expectations can influence toolpath strategy and cycle time.

To keep parts consistent and cost-effective, LK Tools can advise on:

If you have assembly mating features or tight hole-to-hole spacing, include a 2D drawing so we can prioritize inspection and control where it matters most.

CNC routing is commonly used for panel and sheet components across many industries.

The following steps are used to turn your designs into a finished product through CNC routing:

Kerf is the amount of material removed by the cutting tool. In CNC routing, kerf is primarily determined by tool diameter and toolpath strategy. Correct kerf compensation ensures the finished part matches the intended profile and hole sizes.

LK Tools programs toolpaths with proper cutter compensation and validates results through first-part checks. For tight-profile tolerances or critical hole patterns, we may recommend test cuts or measurement checkpoints to confirm the process before running the full batch.

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Get started with our easy-to-use platform and let our experts take care of managing the project from locating the right manufacturing partner to delivery logistics.

We are ISO 9001:2015, ISO 13485, IATF 16949:2016, and AS9100D certified. Only the top shops that apply to become Suppliers make it through our qualification process.

All uploads are secure and confidential