High-performing prototypes and serialized production parts.

STEP | STP | SLDPRT | STL | DXF | IPT | 3MF | 3DXML | PRT | SAT files

All uploads are secure and confidential.

Xometry’s Instant Quoting Engine is covered by U.S. Pat. Nos. 11,086,292, 11,347,201, 11,693,388, 11,698,623, 12,099,341, and 12,189,361. Other patents pending.

Carbon DLS™ Technology Basics

Carbon DLS™ (Digital Light Synthesis™) uses projected light, oxygen-permeable optics, and programmable liquid resins to produce parts with excellent resolution, end-use durability, and strong surface finish potential. The process is sometimes also referenced by the legacy term CLIP (Continuous Liquid Interface Production).

When paired with Carbon’s resin families—often urethane-, epoxy-, or elastomer-based—DLS can support applications that go beyond typical UV-only photopolymer printing. In some programs, DLS can serve as an alternative or bridge to processes like urethane casting or injection molding when you need high performance, repeatability, and production-ready materials without hard tooling.

DLS also enables opportunities such as mass customization, on-demand inventory, and serialized end-use production for small to medium sized parts (project-dependent).

We support Carbon DLS™ resin options based on application needs (strength, flexibility, heat resistance, chemical exposure, and cosmetic requirements). If you don’t see the resin you need, select Material: Other and specify your preferred resin in the quote notes for review.

(If you want, tell me the exact resin menu you offer and I’ll format it into a clean list/table.)

As-printed finish with standard post-processing (support removal + cleaning), suitable for many functional prototypes and production parts.

Color customization may be available for certain resin families and programs. Specify target color requirements and acceptable variation.

Additional finishing options may include dyeing, masking, cosmetic processing, or secondary operations depending on geometry and requirements.

Free shipping available for domestic 3D printing orders ; learn more!

Create strong, functional prototypes that better represent production intent than many standard photopolymer prints.

DLS materials can produce fully dense parts suited for visual models, fit checks, and functional demonstration.

DLS can be used for serialized production of small to medium-sized parts where performance and repeatability are required (project-dependent).

Print in high-performance resin families including urethane-, epoxy-, and elastomer-based systems (availability depends on program needs).

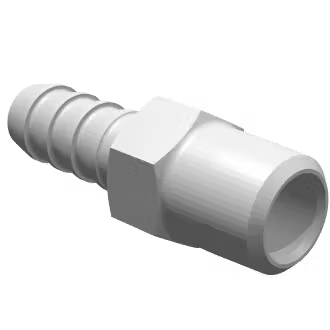

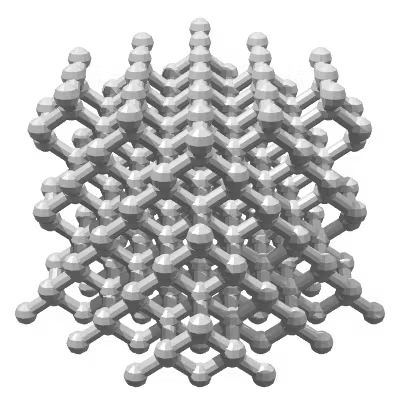

Create geometry that’s difficult to machine or mold—internal channels, lattice structures, and consolidated assemblies.

A strong option for repeat production of parts without hard tooling, particularly for variable designs, serialized parts, and controlled-demand programs.

General tolerances depend on geometry, support strategy, orientation, and post-processing. Certain shapes may be more prone to distortion or variation due to print stresses and curing behavior. Tighter requirements may be possible after a successful prototype build and review of measurement results (case-by-case).

If you have critical dimensions, include a 2D drawing with explicit tolerances and identify critical datums and mating surfaces.

Our quick reference guides let you quickly compare different 3D printing processes!

Carbon DLS differs from some photopolymer processes (such as standard SLA-style printing) because parts typically undergo a secondary thermal cure that helps drive final material properties—activating chemistry beyond UV curing alone (resin dependent). The build can also be more continuous than strictly layer-by-layer processes, which can improve consistency and reduce orientation-driven weakness compared with some additive methods (application and geometry dependent).

For products that need higher mechanical performance, better durability, or a more production-ready resin behavior, DLS can be a strong option—especially when paired with the right resin family and post-processing plan.

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

We are ISO 9001:2015, ISO 13485, and AS9100D certified. Only the top shops that apply to become Suppliers make it through our qualification process.

All uploads are secure and confidential