Rapid Prototyping With Xometry

Rapid 3D printing, CNC machining, sheet metal, and injection molding. Parts ship in days.

- Parts in as fast as days

- 10,000+ manufacturing facilities

- 50+ materials

All uploads are secure and confidential.

What is Rapid Prototyping?

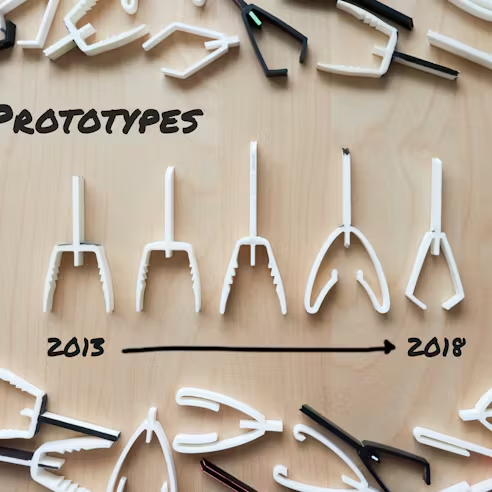

Rapid prototyping is a product development method that utilizes turnkey manufacturing technologies to quickly produce multiple iterations of a component for testing and evaluation. In other words, it is a method of making parts as quickly as possible for hands-on reviews. 3D printing is most often chosen for rapid prototyping because of its affordable price point—typically between $5-50 for a prototype—and its quick turnaround time of 1-3 business days. Other common rapid prototyping processes besides 3D printing include CNC machining, sheet metal fabrication, and rapid injection molding.

Speed and affordability are the key principles of rapid prototyping and allow multiple designs of a prototype to be manufactured at once, or one prototype to be revised and re-made in quick succession. These prototypes provide critical information that helps engineers make design decisions before moving to higher fidelity models for functional testing and production.

Rapid prototyping services can be used to test a full range of designs and materials since the usual financial and time risk is removed from the equation. This mitigates the risk that would occur from moving a project forward without enough information.

Choosing Between Rapid Prototyping Processes

For engineers and product designers in search of rapid prototyping online services to speed up product development cycles, Xometry offers a variety of rapid manufacturing processes that can be used to create prototypes quickly and affordably. Although there are countless different ways that any individual prototype can be produced, it is ultimately up to the engineer to determine which process and material is best suited to their product. In recent years, advancements in additive manufacturing technology have made 3D printing a go-to choice for engineers in search of rapid prototyping solutions: parts can be printed quickly and cheaply in a variety of different metals and plastics.

Rapid 3D Printing Processes

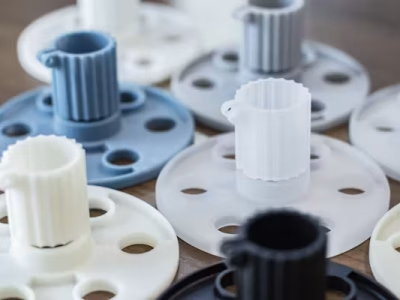

3D printing is the most common rapid prototyping process. The key advantage of using a 3D prototype service is that it is fast and affordable. At Xometry, some 3D printed parts can be built and shipped in as little as a single day at for a few dollars. The three most commonly used 3D printing processes for rapid prototyping are selective laser sintering (SLS), stereolithography (SLA), and fused deposition modeling (FDM).

SLS is one of the most versatile methods for rapid prototyping due to a blend of speed, functional mechanical properties, good detail resolution, and low costs.

SLA has the best surface finish of any 3D printing process and the highest detail accuracy as well as tolerances. SLA is also great at prototyping clear parts, particularly with the QuickClear finish on some materials.

FDM offers a wide variety of engineered thermoplastics such as ABS, PC, and ULTEM. FDM can rapidly produce larger, bulky parts, up to 36” in a single piece.

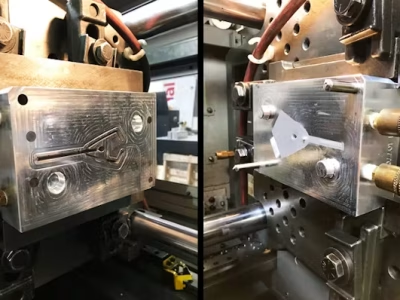

Rapid CNC Machining

CNC milling and CNC turning are great rapid prototyping options for parts that require the prototype to be evaluated in its final material if cut from fully dense stock. Xometry can machine a wide variety of metals and plastics. Many CNC machined parts can be manufactured and shipped within a week. CNC expedite options are available when quoting, and Xometry’s cost-effective, market-based prices enable engineers to order multiple prototypes at once to enable rapid product evaluation.

CNC machined parts have a longer lead time than 3D printing because of the additional machine setup and run time. 3D prints run through a direct digital manufacturing process, with minimal setups or post processing.

Rapid Sheet Metal Fabrication

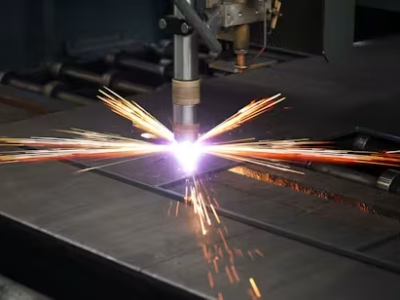

Rapid sheet metal fabrication can be a great option for quick-turn flat parts that require the prototype to be evaluated in its final metal material. These parts can be turned around in a week or less and can often be cost-effective enough to manufacture two or more prototype designs in parallel. Aluminum 5052 is the most common sheet metal material for rapid prototyping, but Xometry also offers a variety of alloys including steels, copper, and stainless.

Rapid sheet metal parts have a comparable lead time to rapid CNC machined parts, but have a longer lead time than 3D printed parts. Much like CNC machining, sheet metal fabrication requires additional machine set-up and run time.

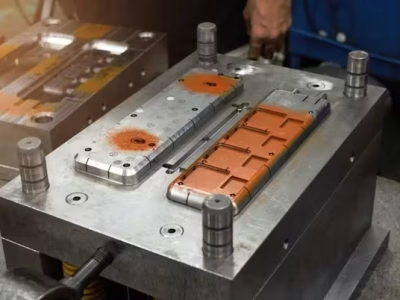

Rapid Injection Molding

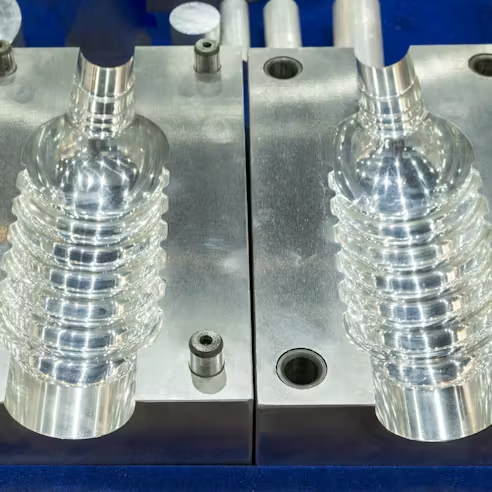

Rapid plastic injection molding is a process that results in a very durable set of identical parts for testing with multiple backup parts. Rapid injection molding can be used for high-fidelity product evaluations and bridge tooling for temporary production at a product launch. The typical lead time for rapid tooling is 2-3 weeks for the initial parts. Xometry’s Quick-Turn Molding option can get parts in as little as five days. Rapid molding may be the best process for rapid prototyping over additive manufacturing or machining due to strict material requirements or mechanical needs that are not achievable in those methods.

While rapid injection molding is slower than 3D printing or CNC machining, it is often critical to see a higher volume of parts as close to the final geometric form as possible. This is where injection molding excels, with high repeatability and near-net final shapes.

Why Choose Xometry for Powder Coating Services?

Endless Options

Choose from thousands of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

Vetted Network

We are ISO 9001:2015, ISO 13485, and AS9100D certified. Only the top shops that apply to become Suppliers make it through our qualification process.

How Xometry's Rapid Prototyping Service Works