Thermal Products Overview

⏱️ 24h Quote 📈 Prototype + EVT / DVT / PVT

📑 PPAP / FAI / Cpk 🚚 Supply Chain + Logistics Integration

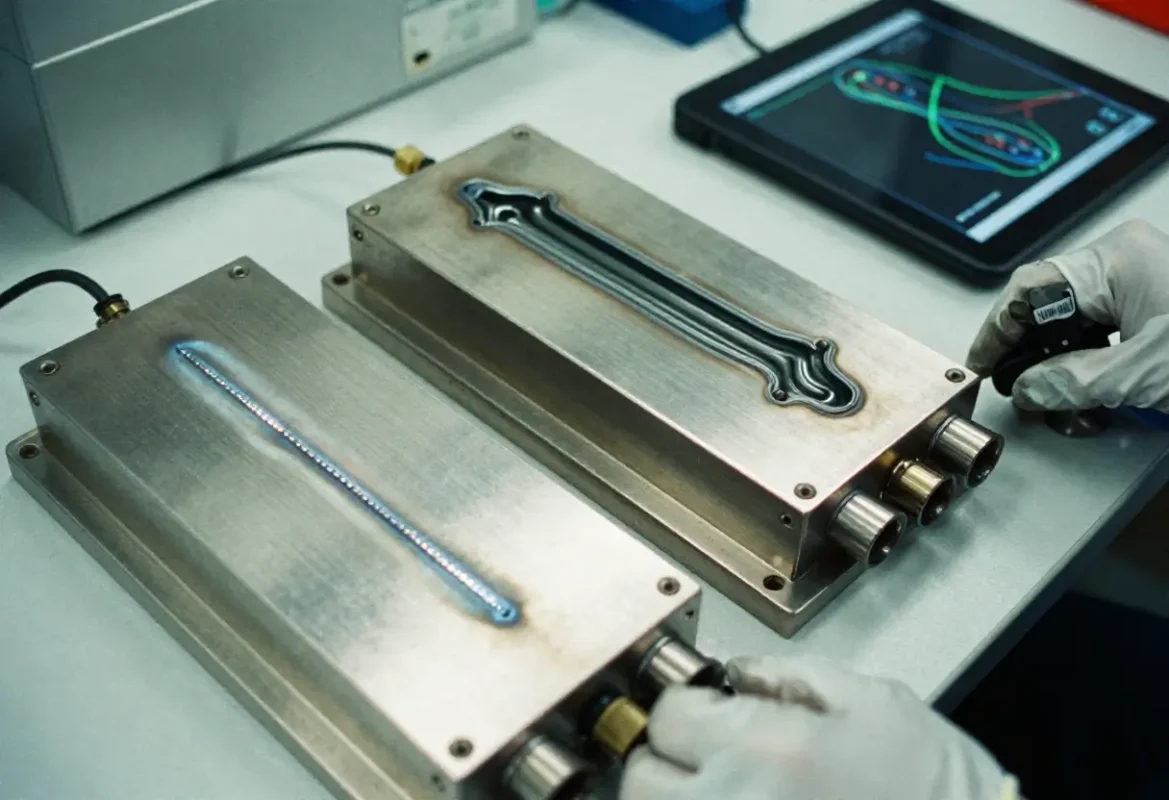

FSW / Laser / Microchannel

Cold Plates

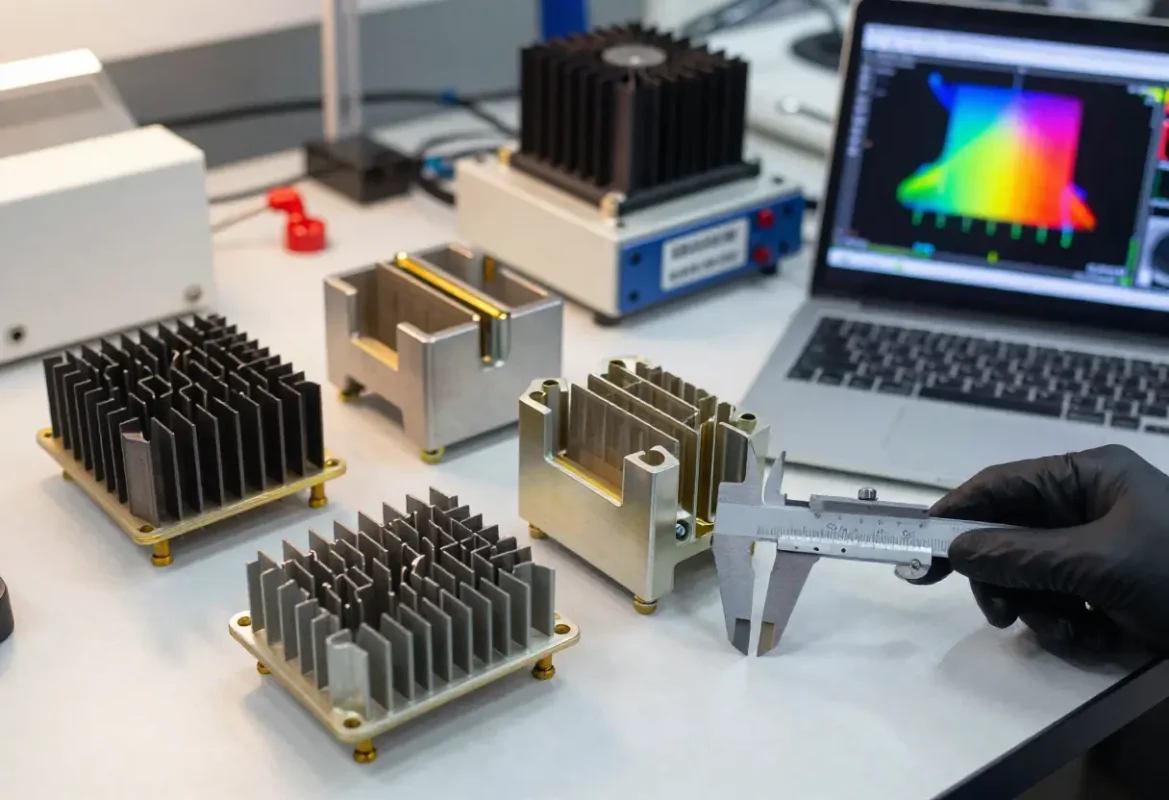

Skived & Extruded Options

Heat Sinks

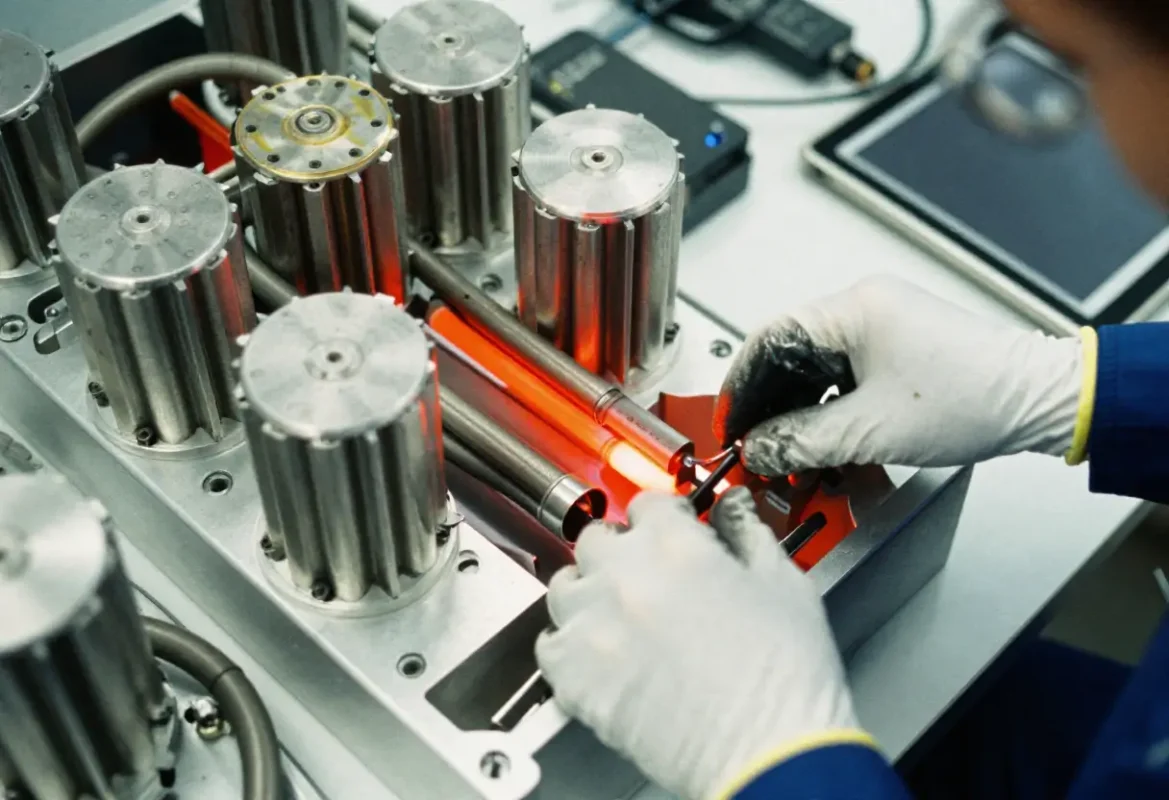

Heat Pipes & Vapor Chambers

HP / VC

Thermal Product Families

Liquid Cold Plates (FSW / Laser / Microchannel)

FSW and laser welding for robust, leak‑resistant cold plates; microchannel and serpentine architectures for high heat flux and low thermal resistance.

Skived Heat Sinks

High‑performance skived fins for compact form factors and optimized spreader coupling. Available bonded, extruded or skived, tuned for airflow, acoustic and thermal budgets.

Heat Pipes & Vapor Chambers

2D vapor chambers and cylindrical heat pipes integrated into machined bases, enclosures and frames for rapid heat spreading and hotspot leveling.

Cooling Module Assemblies

Turnkey thermal modules: cold plate + manifold + hoses + sensors + mechanical integration—built to manufacturing SOP with validation and packaging for field service.

Capabilities & Typical Specifications

Design & Simulation

CFD, thermal network modeling, 0D/1D hydraulic sizing, ΔT–flow–power mapping and correlation to lab tests to predict part performance before tooling.

Manufacturing Processes

CNC machining, FSW, laser welding, brazing, skiving, extrusion, and assembly—plus PPAP-ready process controls and SPC monitoring.

Validation & Testing

Thermal performance mapping, pressure‑drop curves, leak testing (pressure decay, helium), vibration, shock and thermal cycling.

Materials

Aluminum (various alloys), copper, copper alloys, selective plating and anodize options; barrier coatings for mixed-metal systems.

Thermal Ranges

Designs for heat fluxes from 1 W/cm² to > 200 W/cm² depending on architecture (microchannel, pin‑fin, vapor chamber assisted).

Hydraulic Targets

Flow rates and pressure drops tuned to customer pump budgets (from 50 L/min depending on module); cavitation and NPSH evaluated at system level.

How We Develop a Thermal Component

Requirements & Interfaces

Power map, mechanical envelope, electrical interfaces, environmental and reliability targets—set hydraulics and pump budget.

Concept & Architecture

Choose cold plate vs heat pipe vs vapor chamber vs skived sink; define manifolds and flow balancing approach.

Simulation & Optimization

CFD and thermal network correlation to evaluate ΔT, flow balance and pressure drop; iterate channel geometry and spreader thickness.

Prototype & Correlation

Rapid machined prototypes, ΔT–flow–power mapping, pressure curves, and revision for manufacturability.

Validation & Production

Leak and burst testing, vibration & thermal cycle, PPAP/FAI and process window setup for scale production.

Performance & Reliability Validation

We validate thermal performance in controlled labs: steady-state ΔT mapping across flows, transient response, pressure-drop curves for hydraulic sizing, leak detection (pressure decay and helium), and environmental tests (vibration, thermal cycling) to ensure long-term reliability.

Where Thermal Products Are Used

Automotive & EV

Inverter cold plates, OBC / DC-DC cooling, battery structural plates and traction module thermal management.

Power Electronics & Energy

Rectifiers, converters, UPS, storage inverters and DC fast charging thermal assemblies.

Robotics, UAV & Specialty Systems

Compact VC/HP modules for tight envelopes, gimbals and optics cooling and ruggedized industrial electronics.

Manufacturing & Supply Chain

Production-ready thermal hardware requires process alignment: welding method selection, fixture & tooling design, cleanliness and brazing controls, and vendor-managed inventory for modules. We support DDP logistics and U.S. Dallas warehouse stocking for programs needing regional fulfillment.

CNC Machining & Fixtures

Tight tolerances, sealing grooves, and fixture design for repeatable assemblies.

FSW & Laser Welding

Robust joining for high vibration, and precision seams for microchannel and manifold sealing.

Assembly, Leak & QA

Pressure decay, helium leak, hydrostatic and end-of-line thermal checks integrated with PPAP/FAI.

Ready To Specify A Thermal Solution?

Upload your power map, 2D/3D models and system constraints. We’ll return feasibility notes, ΔT–flow–power targets and an indicative path from prototype to validated production within 24 business hours.