Liquid Cold Plates (FSW, Laser & Microchannel)

We design and manufacture thermal hardware for high‑power electronics and EV systems. From FSW and laser‑welded cold plates to skived heat sinks, heat pipes & vapor chambers, and complete cooling module assemblies—our focus is on performance, reliability and manufacturability at scale.

🧊 Liquid cold plates 🌀 Microchannel 🛠️ Skived sinks ♨️ Vapor chambers

🧩 Module integration 🔬 Lab validation

Friction‑Stir Welded Plates

FSW

Laser‑Welded Microchannels

Laser

High Heat‑Flux Architectures

Microchannel

What We Deliver

Turnkey cold plate hardware that meets thermal and system budgets—engineered for manufacturability and reliability. Deliverables include CAD, ΔT–flow–power maps, pressure‑drop curves, leak test data, and PPAP/FAI packages for production release.

When to Choose Each Technology

FSW is preferred for high‑vibration automotive use and robust joints. Laser welding enables tighter channels and complex manifolds for compact systems. Microchannel architectures deliver the highest heat flux handling at the cost of manufacturing complexity and pressure drop.

Capabilities

Channel Architectures

Joining & Sealing

FSW, laser welding, brazing and gasketed options with groove design optimized for life and leak resistance.

Hydraulics & Manifolds

Header sizing, flow balancing, manifolds and quick‑connect options matched to pump budgets and system layouts.

Design Variables & Typical Specifications

Materials & Coatings

Aluminum alloys for weight and cost, copper for local conductivity, selective plating and anodize for corrosion control; mixed‑metal barriers as needed.

Channel & Fin Geometry

Channel widths 0.3–5.0 mm, depths 0.5–6 mm, aspect ratios tuned for pressure drop vs heat transfer; pin‑fin spacing and height optimized for flow regime.

Hydraulic Targets

Designs for flows from 50 L/min and pressure drops from a few 10s of mbar to several bar depending on architecture; pump NPSH considered at system level.

From Requirements To Verified Cold Plate

Requirements & Power Map

Collect power map, target ΔT, envelope, mounting and environmental constraints; set pump & pressure budgets.

Architecture Selection

Choose FSW, laser, brazed or gasketed approach and select channel style based on heat flux and manufacturability.

CFD & Hydraulic Optimization

Simulate temperature fields, pressure drop and flow balance; iterate channel and manifold layout for target performance.

Prototype & Characterization

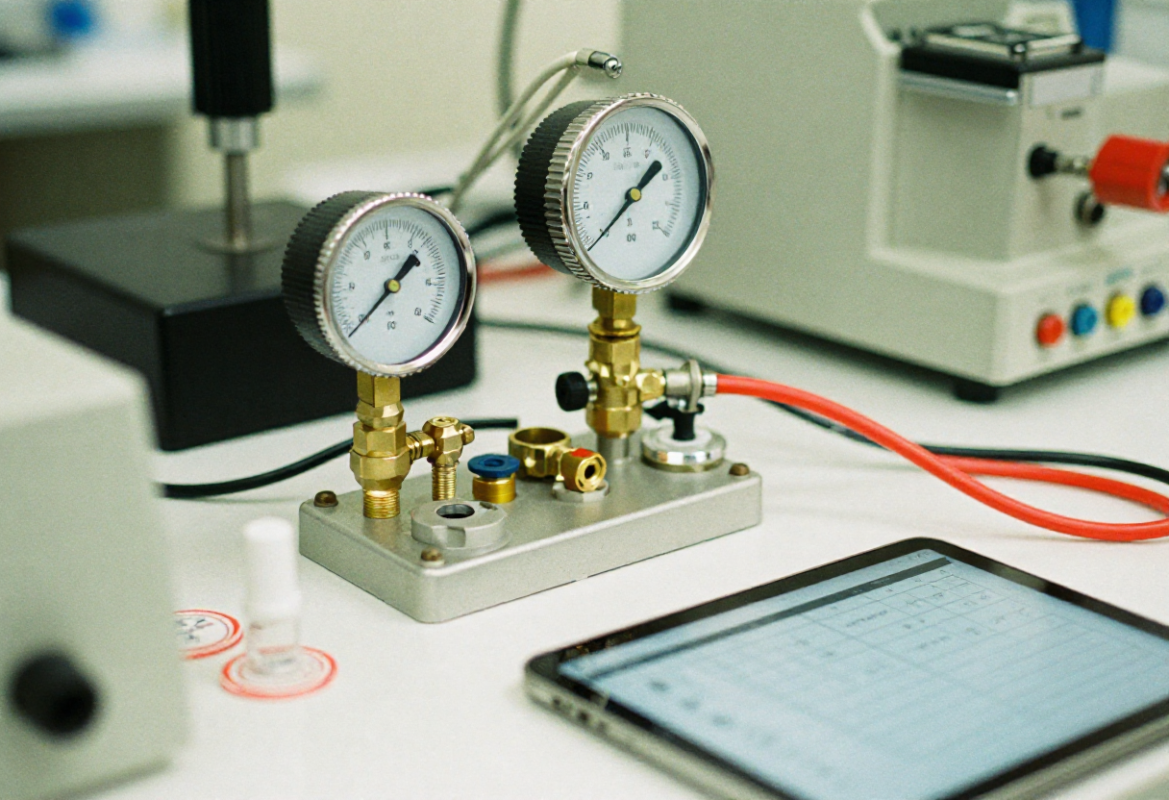

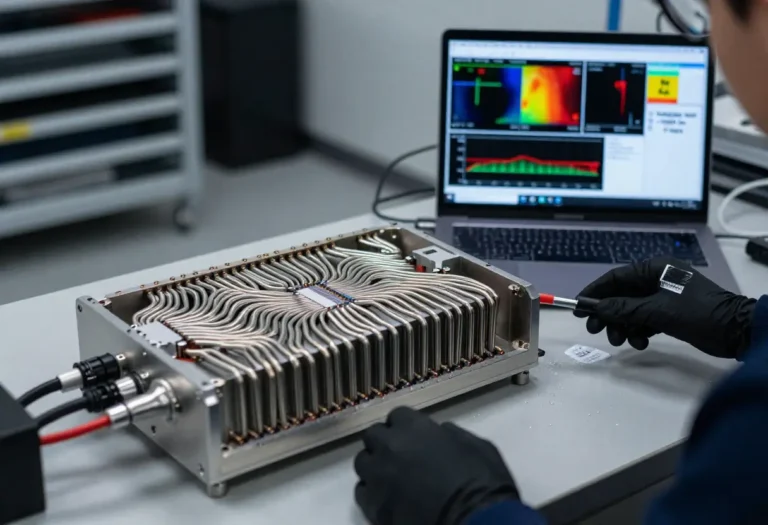

Prototype builds, ΔT–flow–power mapping, pressure‑drop curves and pump point determination; leak checks and burst tests.

Validation & Production

Environmental testing, vibration, PPAP/FAI package and process window setup for scale production.

Performance Mapping & Reliability Testing

We validate thermal performance across flow rates: steady‑state ΔT mapping (power vs ΔT vs flow), transient response, pressure‑drop curves, leak detection (pressure decay, helium), vibration, shock and thermal cycle testing to confirm life and sealing integrity.

Technology Selection Guidance

| Technology | Best For | Tradeoffs |

|---|---|---|

| FSW Cold Plates | Automotive, high vibration; robust, low leak risk | Moderate channel complexity; tooling investment for FSW |

| Laser‑Welded Plates | Complex manifolds, fine channels, compact layouts | Higher precision welding, cleanliness controls, potential for higher NRE |

| Microchannel Plates | Very high heat flux, hotspot control | Higher pressure drop; manufacturing tolerance & fouling risk |

| Gasketed / CNC | Rapid prototyping, serviceable designs | Gasket life & maintenance; not always suitable for high vibration |

Typical Applications & Industries

Automotive & EV

Inverter cold plates, OBC thermal modules, battery cooling integration with vibration and life targets.

Power Electronics

Converters, rectifiers, UPS and Fortune power modules where thermal control drives reliability.

High‑Performance & Industrial

Dense compute, telecom power modules, laser diodes and industrial drives with compact envelopes.

From Prototypes to Volume Key Services

- CAD / drawing package, GD&T and BOM

- ΔT–flow–power maps and pressure‑drop curves

- Leak test results (pressure‑decay and helium) and burst test data

- Environmental & vibration test reports and PPAP/FAI package

Artifacts

Table showing artifacts and their contents

| Artifact | Contents |

|---|---|

| Thermal Map | Power levels, flow rates, ΔT results, sensor locations |

| Hydraulic Curve | Flow vs Pressure; pump operating point recommendations |

| Leak & Burst Report | Pressure decay, helium leak rates, safety margins |

Example: EV Inverter Cold Plate

Project: high‑power inverter with localized hotspots. Approach: microchannel sections under hottest MOSFET clusters, serpentine parallel branches elsewhere, laser‑welded manifolds for complex routing. Result: ΔT reduced 20–35% over baseline, pressure drop within pump budget, and validated vibration life >1000 hours with no leaks.

Get Started with a Cold Plate Design

Upload your power map, CAD models and pump/flow constraints. We will respond within 24 business hours with feasibility comments, recommended architecture (FSW, laser or microchannel), and indicative ΔT–flow–power targets and next steps.