Cooling Module Assemblies — Turnkey Liquid Cooling Systems

We design and deliver integrated cooling modules that combine cold plates, pumps, manifolds, sensors and controls into fully tested, production‑ready subsystems. Our modules are optimized for hydraulic balance, thermal performance and serviceability — reducing integration risk and accelerating product launches for EV, datacenter, telecom and industrial applications.

- Complete assemblies: cold plate + manifold + pump + sensors + filtration

- Validated hydraulics and leak containment for field reliability

- Configurable controls, redundancy and serviceable components

Liquid Cold Plates

FSW, laser and microchannel cold plates for high‑flux modules.

Integrated Cooling Modules

Turnkey assemblies with pumps, sensors and leak containment.

Vapor Chambers & Heat Pipes

Thin spreaders and routed heat pipes for hotspots and path routing.

What is a Cooling Module Assembly?

A cooling module assembly is a single, tested unit that integrates thermal interfaces (cold plates or vapor plates), hydraulic plumbing (manifolds, tubing, quick‑connects), pumps, sensors, controllers and containment features. By delivering a single BOM item that is validated for hydraulic and thermal performance, we remove supplier coordination complexity and reduce integration risk for OEMs.

We engineer modules for serviceability (replaceable pump cartridges, filters), leak containment and configurable electrical interfaces to align with customer system requirements.

Turnkey Integration

Reduce procurement complexity and assembly time. Modules arrive functionally validated and ready to install into your system harness and coolant loop.

Optimized Hydraulic Performance

Manifolds and flow paths are modeled and tuned to deliver balanced flow, minimal pressure drop and low parasitic power at the system flow target.

Serviceability & Safety

Designs include serviceable filters, modular pump cartridges and leak detection options to minimize downtime and ease field service.

Design & Engineering Capabilities

We deliver system‑level engineering that covers CAD integration, 3D CFD and hydraulic network modeling, pump selection, control logic, and electrical integration. Our focus is on balancing thermal targets, acoustic limits and lifecycle requirements.

Typical engineering scope

- CFD & hydraulic simulation (steady & transient)

- Pump & controller selection and firmware integration

- Manifold balancing and quick‑disconnect design

- Serviceability and safety architecture (leak sensors, containment)

Manufacturing & Assembly

Modules are assembled in controlled environments with defined torque, harness routing and traceable documentation. Production includes cold plate join (brazing or mechanical), manifold assembly, pump mounting, sensor wiring and a staged test flow (electrical, leak, hydraulic, thermal).

Quality gates

We assess coolant chemistry, ambient exposure and galvanic concerns to recommend barrier coatings or mixed‑metal mitigation strategies.

Materials, Pumps & Components

We qualify and source components to meet environment and lifetime expectations. Typical choices: copper/aluminum cold plates, stainless/plated manifolds, PTFE/EPDM tubing and industrial quick‑connects. Pump options include BLDC, canned rotor and redundant pump architectures for critical systems.

Serviceability considerations

Field replaceable pump cartridges, accessible filters and designed drain paths reduce mean time to repair and simplify maintenance procedures.

Representative Module Specifications

Representative ranges. Final specification is defined during engineering based on power map, ΔT targets and system constraints.

Flow Rate

0.5 — 10 L/min per cold plate (varies by module)

Pressure Drop

0.1 — 1.5 bar across module at design flow

Pump Power

5 — 60 W depending on head and redundancy

Thermal Resistance

0.02 — 0.4 °C/W (module-level, application dependent)

| Parameter | Typical Range | Notes |

|---|---|---|

| Coolant | Water/Glycol, Dielectric fluids | Selected for conductivity, freeze point and electrical safety |

| Pump type | BLDC, canned rotor, redundant | Redundancy for fail-safe configurations |

| Leak rate (post-assembly) | <1e-6 mbar·L/s typical | Helium or vacuum decay tests per customer spec |

| Operating temp | -40 °C to +85 °C (typical) | Extended ranges available on request |

| Lead time | Prototypes: 3–6 weeks • NPI: 8–16 weeks | Depends on custom electronics and approvals |

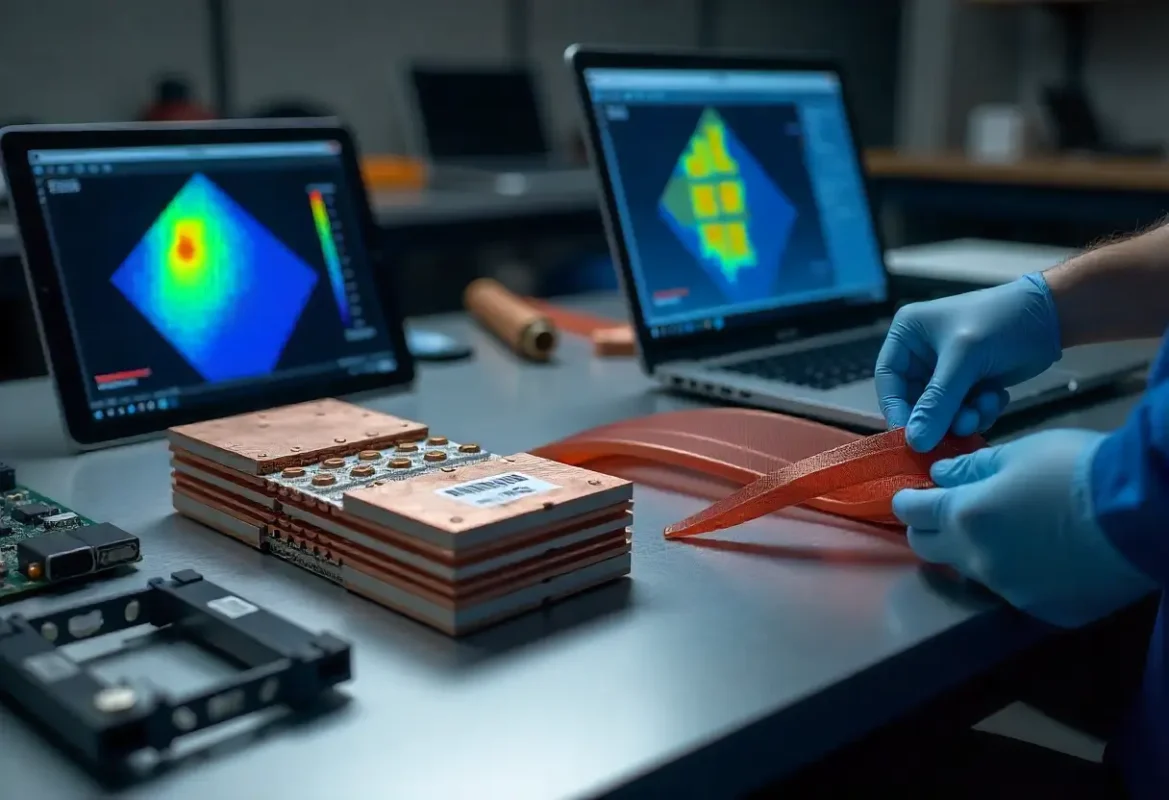

Thermal & Hydraulic Validation

Validation deliverables

Flow/pressure curves, ΔT vs flow charts, IR thermal maps, transient response plots and recommended adjustments for production readiness.

Leak, Vibration & Environmental Testing

Leak testing (helium/vacuum), vibration, thermal cycling and shock are performed to represent anticipated field conditions. EMI and ingress tests are added when modules include electronics that must meet compliance or ruggedization requirements.

Safety & compliance

Leak containment design, interlocks, over‑current protections and selectable fail‑safe modes are part of high‑reliability module designs.

Applications

EV Power Electronics & Inverters

Automotive-grade modules with redundancy, leak containment and rugged connectors.

Datacenter & HPC

Rack and blade modules supporting high-power accelerators with minimal rack cooling cost.

Telecom & Networking

Shelf-level modules with hot-swap serviceability and monitored flow control for 24/7 operation.

Representative Projects

Redundant EV Charger Module

Dual pump architecture with automatic failover and leak detection reduced downtime risk and met automotive lifecycle targets.

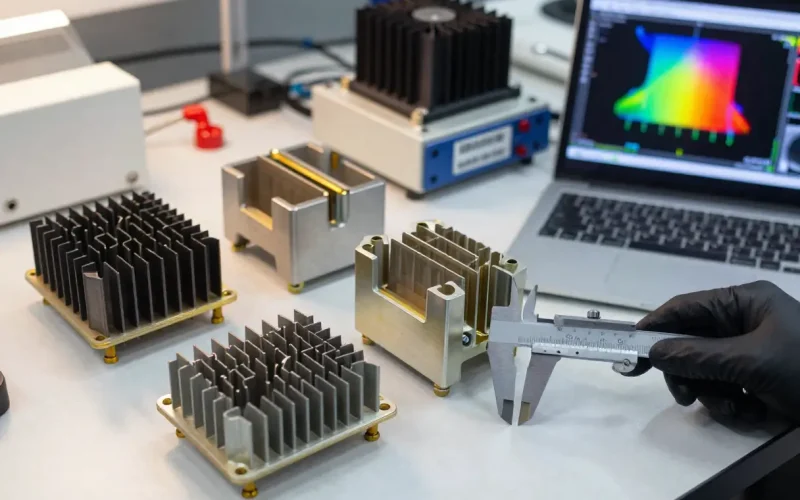

Skived Heat Sinks

High‑performance skived fins for compact form factors and optimized spreader coupling. Available bonded, extruded or skived, tuned for airflow, acoustic and thermal budgets.

Frequently Asked Questions

Can you integrate customer-specified pumps or controllers?

Yes — we validate electrical interfaces, integrate and test customer-specified pumps or recommend industry‑proven alternatives for life and compatibility.

What leak containment strategies are available?

Options include drip trays, leak sensors, routed drainage, shut‑off quick‑connects and service access panels to minimize risk and simplify maintenance.

Do you support certification documentation?

We provide documentation packages and can support coordination of third‑party testing required for regulatory or industry certifications as part of NPI.

Ready to Integrate a Cooling Module?

Share your power map, coolant preference and service model. We’ll return feasibility notes, recommended architectures and a prototype plan — typically within 24 business hours.