Lighting & Mechanical Enclosures — Weatherproof, Thermally Integrated, Production‑Ready

We design and manufacture lighting and mechanical enclosures that combine structural integrity, environmental protection and integrated thermal/optical features. Metal, plastic and composite enclosures are developed for outdoor, architectural, industrial and consumer lighting markets with IP, IK, EMC and finish options.

- Die cast, extruded, fabricated and injection molded enclosures

- Integrated heatsinks, lens retention, gaskets and mounting interfaces

- IP65–IP69K sealing, IK impact protection and EMC management for electronic assemblies

EV Thermal Subsystems

Die Cast Housings

Precision Machining

What We Make

We produce complete enclosures and subassemblies for lighting and mechanical systems: die cast housings with integrated fins, extruded thermal profiles and lenses, injection molded bezels, stamped and welded chassis, sealed junctions, and complete luminaire assemblies with drivers and harnessing. Each design is evaluated for thermal, optical, mechanical and serviceability requirements.

Design & Engineering

Our enclosure engineering balances mechanical stiffness, thermal dissipation, optical mounting and manufacturability. We run CAD for fit and tolerance, FEA for stress and modal behavior, CFD and thermal simulations for LED arrays, and optical alignment studies to ensure lens and reflector interfaces are repeatable.

Key deliverables

CAD models, thermal maps, assembly drawings, tolerance stack analysis, and DFM reports with material and finish recommendations.

Optical & Mechanical Integration

We design lens retention features, baffle systems, reflector seats and gasket bosses to ensure optical alignment and luminous efficacy. Mechanical features include mounting bosses, snap fits, captive fasteners and service access for driver maintenance.

Serviceability

Modular driver bays, quick‑disconnects, removable optics and replaceable gaskets reduce field service time and extend product life.

Materials & Finishes

Material selection is driven by thermal requirements, appearance and environment: die cast or extruded aluminum for thermal mass and conduction; stainless or coated steel for rugged enclosures; PC/ABS blends for impact resistance; and composite housings for corrosion resistance and weight savings.

Surface finishes

Anodize (clear & color), powder coat, wet paint, electroplating, PVD, texturing, and soft‑touch coatings. Optical surfaces are precision machined or polished for glare control and aesthetics.

Die Casting & CNC Finishing

Die casting produces complex housings with integrated fins and bosses. We offer vacuum/low‑porosity processes plus CNC finishing for critical sealing surfaces and mounting faces.

Advantages

High thermal conductivity, integrated geometry, tight tolerance after machining and consistent cosmetic finish after plating or coating.

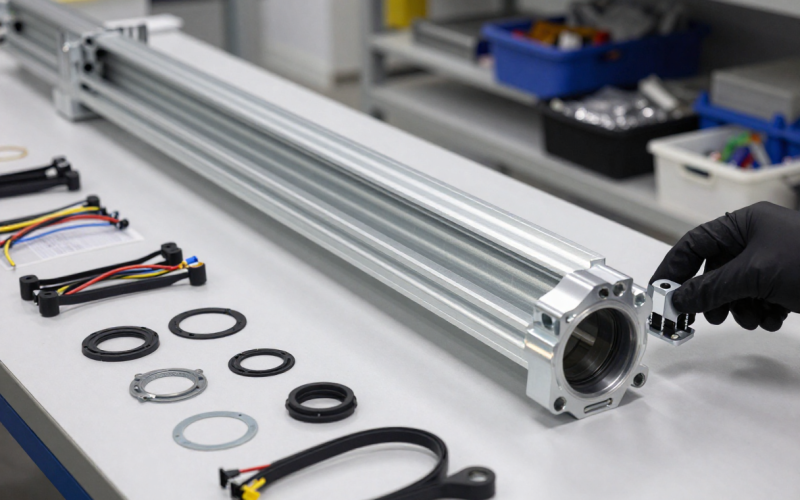

Extrusion & Fabrication

Extruded aluminum profiles are used for linear fixtures and rails with engineered fin patterns. Fabricated sheet metal enclosures are laser cut, bent and welded for cost‑effective housings and reflectors.

Secondary ops

Cut‑to‑length, CNC machining, tapping, powder coat, and assembly into finished luminaire modules.

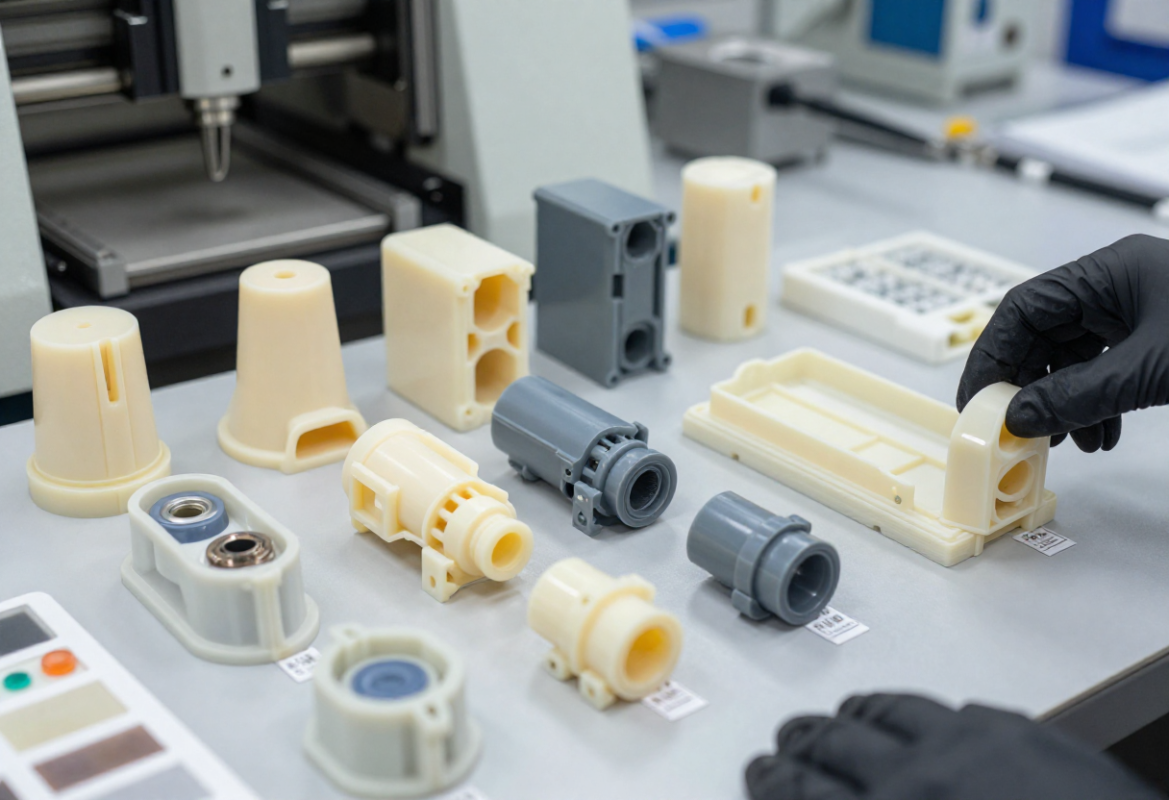

Injection Molding & Composites

Injection molding for bezels, end caps and optical mounts allows complex internal features and snap fits. Composite housings provide corrosion resistance and weight reduction for marine or harsh outdoor environments.

Overmolding & inserts

Overmolded seals and captive inserts simplify assembly and improve sealing without extra hardware.

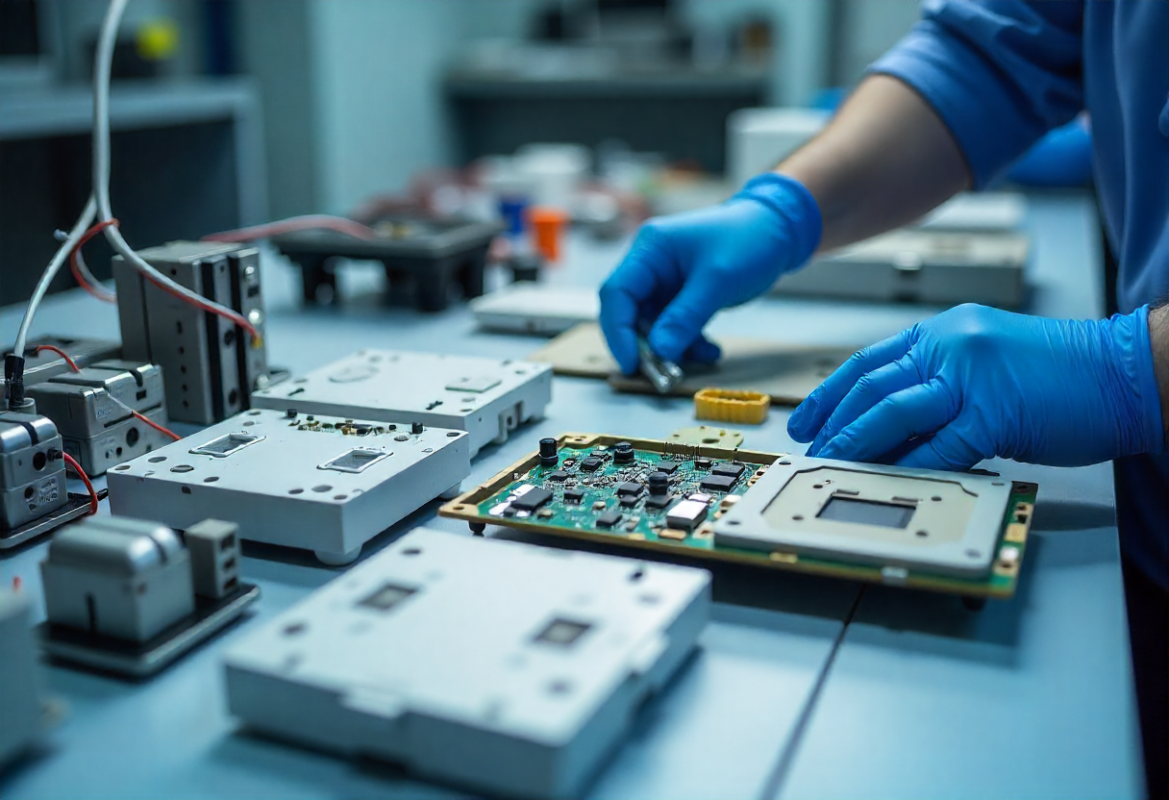

Assembly & Final Test

We provide full assembly with driver installation, harnessing, potting or conformal coating, performance burn‑in, photometric testing and IP/IK validation prior to packaging and shipment.

Test capabilities

Photometric integrator sphere, thermal chambers, salt spray, UV aging, vibration and ingress tests to customer or industry standards.

Sealing, IP & Impact Protection

We design gasket bosses, drainage channels, cable gland interfaces and interactive seals to achieve IP65–IP69K ratings. IK impact protection is achieved through material choice, reinforcement ribs and protective lens designs. We verify through standardized testing and provide recommendations for installation orientation and maintenance access.

Gasket & sealing options

Compression gaskets, overmolded seals, silicone O‑rings, double‑seal construction and controlled torque patterns for uniform compression and long seal life.

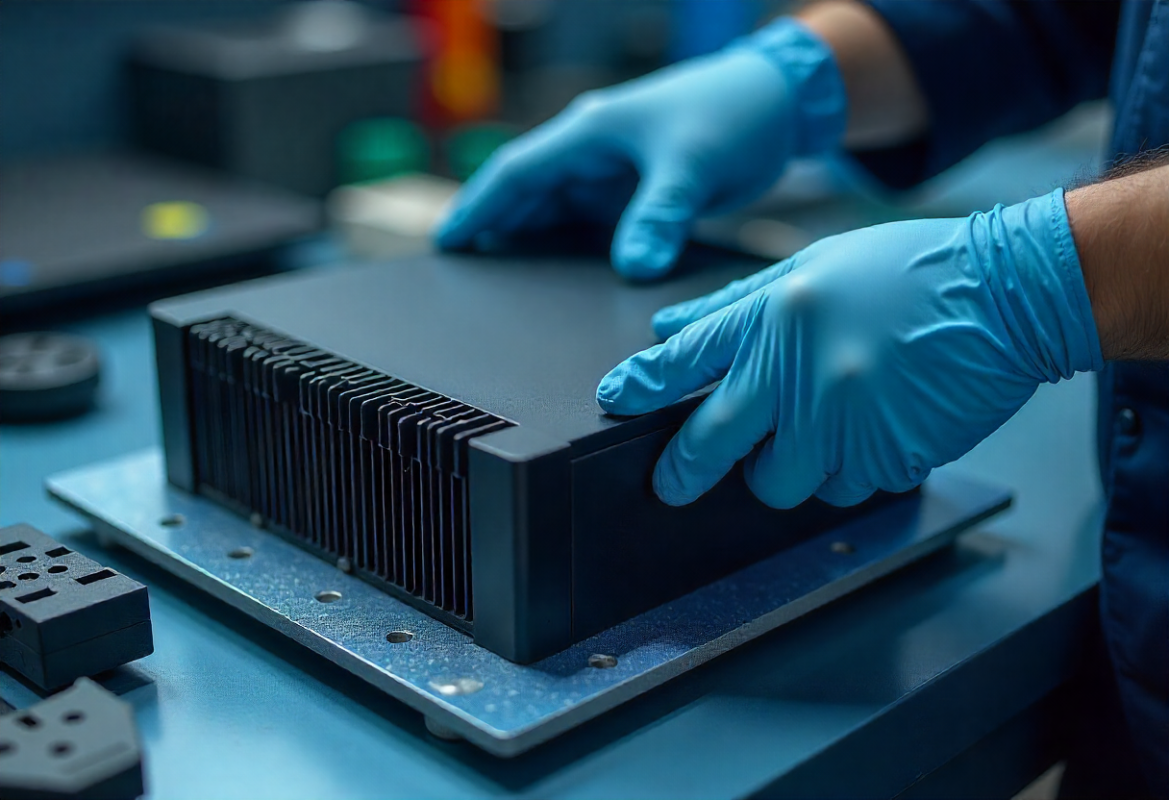

Integrated Thermal Management

Enclosures often double as heatsinks. We design integrated fin geometry, thermal vias, vapor chambers, and cold plate interfaces. CFD and prototype thermal mapping ensure LED arrays and drivers meet junction temperature and lifetime targets.

Thermal features

Integrated fins, thermal pads, bonded cold plates, conduction paths and optional active cooling interfaces for high‑power luminaires or electronics enclosures.

Representative Specifications

Typical design ranges and targets used during initial scoping. Final requirements are set during engineering and prototyping.

IP Rating

IP54 — IP69K depending on sealing strategy

IK Impact

IK05 — IK10 for impact zones; reinforced lenses for IK ratings

Operating Temp

-40 °C to +85 °C typical; extended ranges with specific materials

Thermal Path

Integrated fins and conduction paths; Rθ targets defined per LED package and array

| Parameter | Typical Range | Notes |

|---|---|---|

| Materials | Die cast/extruded Al, steel, PC/ABS, composites | Choose for thermal, mechanical and corrosion needs |

| Finish | Anodize, powder coat, wet paint, plating | Specify color/texture and UV resistance |

| Lens & optic options | Glass, PMMA, PC; opal or clear | Specify transmission, UV resistance, and impact |

| Prototype lead time | Days–4 weeks | Depends on process (fab, cast, mold) |

Applications

Architectural & Street Lighting

Robust housings, glare control optics, thermal rails and serviceable driver bays for long life in outdoor environments.

Industrial & Hazardous Area

Explosion‑proof options, sealed junctions and corrosion resistant finishes for harsh environments.

Retail & Display

Aesthetic finishes, thin bezels and integrated mounts for consumer-facing fixtures.

Representative Projects

Die Cast Outdoor Floodlight

Integrated thermally‑active housing with cast fins, silicone gasket, IP66 rating and modular driver compartment for field service. Passed salt spray and UV tests for coastal installations.

Extruded Linear Architectural Rail

Extrusion with integrated fins, lens channel and CNC machined end caps; anodized finish and supplied as kitted, pre‑wired assemblies.

Frequently Asked Questions

How do you ensure IP ratings on assembled luminaires?

We design for uniform gasket compression, controlled torque patterns, appropriate drain/weep channels, and validate through ASTM/IEC ingress testing. We also advise on field installation orientation to preserve rating.

Can you integrate optics and thermal management in the same housing?

Yes — we co‑design lens retention, light engine mounting and conduction paths (fins, thermal pads, cold plates) so the enclosure serves both optical alignment and heat dissipation roles.

Do you provide UL/CE documentation for lighting enclosures with electronics?

We support documentation packages for CE/EMC and can coordinate UL/EN safety testing with certified partners. We provide mechanical and thermal test reports required for certification submissions.

Start Your Enclosure Project

Upload your CAD, target IP/IK ratings and expected volumes. We’ll return DFM feedback, material and sealing recommendations and a prototype plan — typically within 24 business hours.