Extruded Components Aluminum Profiles & Rubber/Silicone Extrusions

We design and produce custom extruded profiles for structural frames, thermal rails, seals, gaskets and decorative trims. Capacities include aluminum extrusion, rubber and silicone extrusion, co‑extrusion and post‑process machining and finishing to deliver production‑ready parts for demanding industries.

- Custom die design and prototype profile validation

- Aluminum structural & thermal profiles, elastomer seals and silicone extrusions

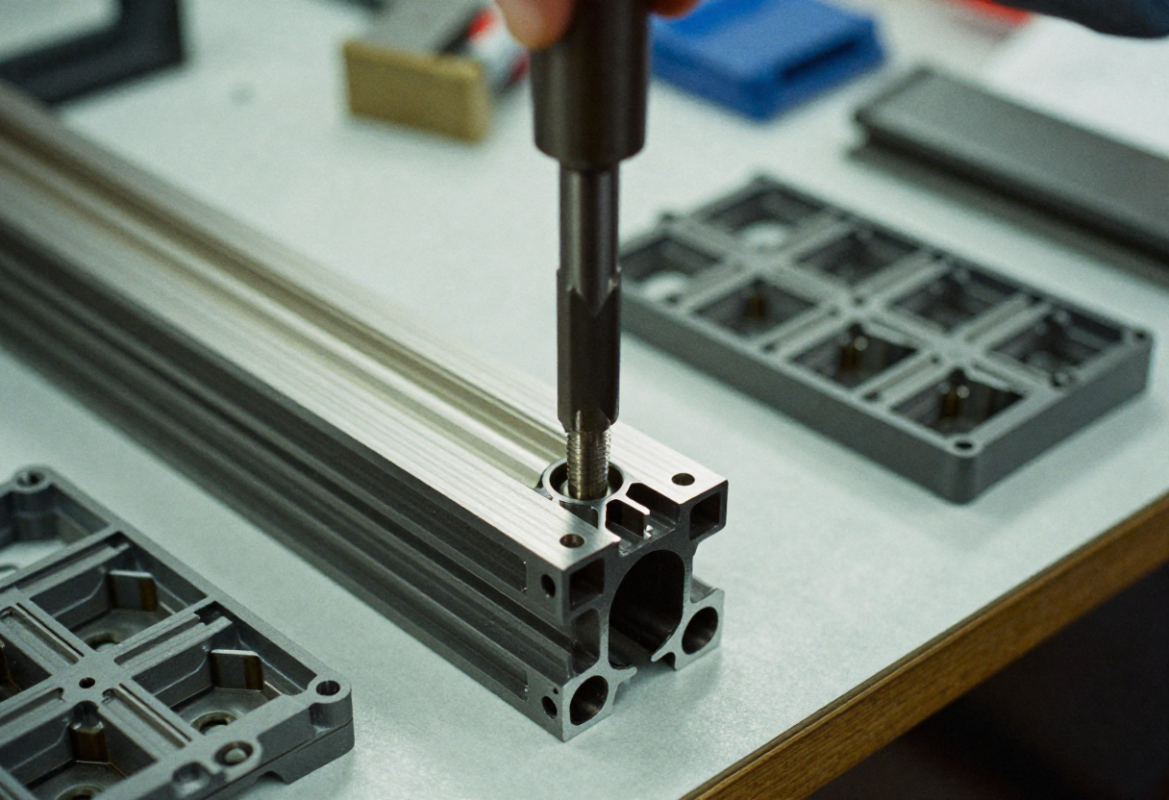

- Secondary operations: cut‑to‑length, CNC machining, drilling, anodize and assembly

Aluminum Profiles

Rubber & Silicone

Secondary Operations

What is an Extruded Component?

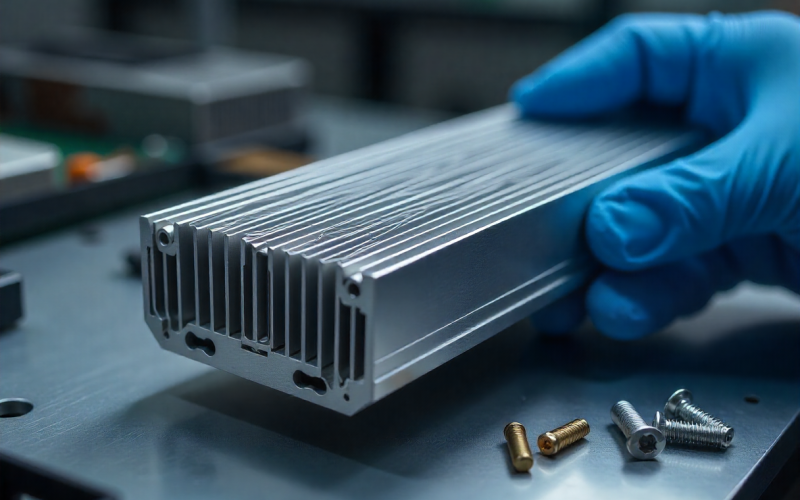

Aluminum Extrusions — Structural & Thermal Profiles

We extrude 6061 and 6063 alloys into complex profiles used for housings, frames, rails and thermal fins. Profiles can be designed with integrated mounting features, internal channels for coolant, and thermal fin geometries for passive heat dissipation.

Typical aluminum capabilities

- Profile cross‑section complexity up to 200–300 mm wide (depending on press)

- Wall thickness control, tight tolerances on critical features

- Post‑extrusion stretching, straightening and aging for mechanical properties

Secondary machining & finishing Cut‑to‑length, CNC

Cut‑to‑length, CNC milling/drilling/tapping, surface treatments (anodize, powder coat), thermal anodize for improved heat transfer and mechanical fastening integration.

Rubber & Silicone Extrusions — Seals, Gaskets & Flexible Profiles

We extrude EPDM, NBR, FKM (Viton), silicone (VMQ/LSR-compatible compounds) and TPE/TPU for seals, cable gaskets, edge trims and vibration isolators. Co‑extrusion and overmolding are available to combine different durometers or materials in a single profile.

Design considerations

We recommend consistent wall thickness, controlled radii and draft-friendly features to avoid die swell and ensure dimensional stability. Tooling includes mandrels and vacuum sizing for tight tolerances.

Post‑process & vulcanization

Die Design & Tooling

Tooling lifecycle

Secondary Operations & Assembly

Co‑extrusion & overmolding

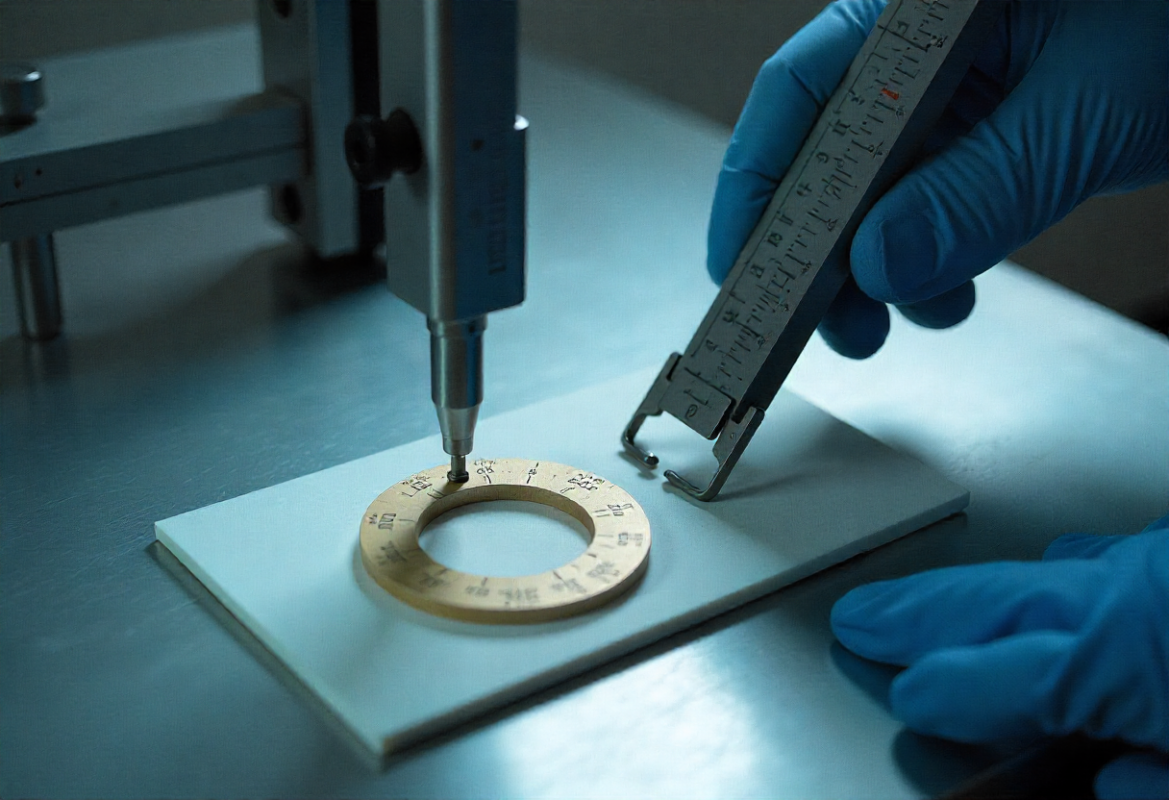

Tolerances, Sizes & Typical Specifications

Profile Width

From a few millimeters to several hundred millimeters depending on press capacity

Wall Thickness

As thin as 0.8 mm for aluminum/metal ribs; elastomers typical 1.0 mm and up

Length

Continuous coils or cut‑to‑length up to specified lengths; tight length tolerance for assemblies

Tolerances

Aluminum: ±0.1–0.5 mm post‑extrusion; tightened after machining. Elastomers: ±0.2–1.0 mm depending on feature.

| Parameter | Range | Notes |

|---|---|---|

| Materials | Aluminum 6061/6063; EPDM, Silicone, NBR, FKM, TPU | Select for mechanical, thermal and chemical environment |

| Surface finish | Anodize, powder coat, mill finish | Anodize recommended for corrosion resistance and aesthetics |

| Co-extrusion | Yes | Soft + rigid combinations for integrated seals and carriers |

| Prototype lead time | 2–4 weeks | Dependent on die complexity and material |

Quality, Inspection & Traceability

Environmental & mechanical testing

Applications

Thermal Rails & Heatsink Profiles

Aluminum extrusions with integrated fins and mounting features for passive cooling and thermal management.

Seals, Gaskets & Weatherstrips

Elastomer extrusions for doors, enclosures, and exposed outdoor equipment with UV and ozone resistance.

Architectural & Trim

Decorative aluminum trims, window frames and custom channel profiles with anodize/color finishes.

Representative Projects

Aluminum Thermal Rail for Power Module