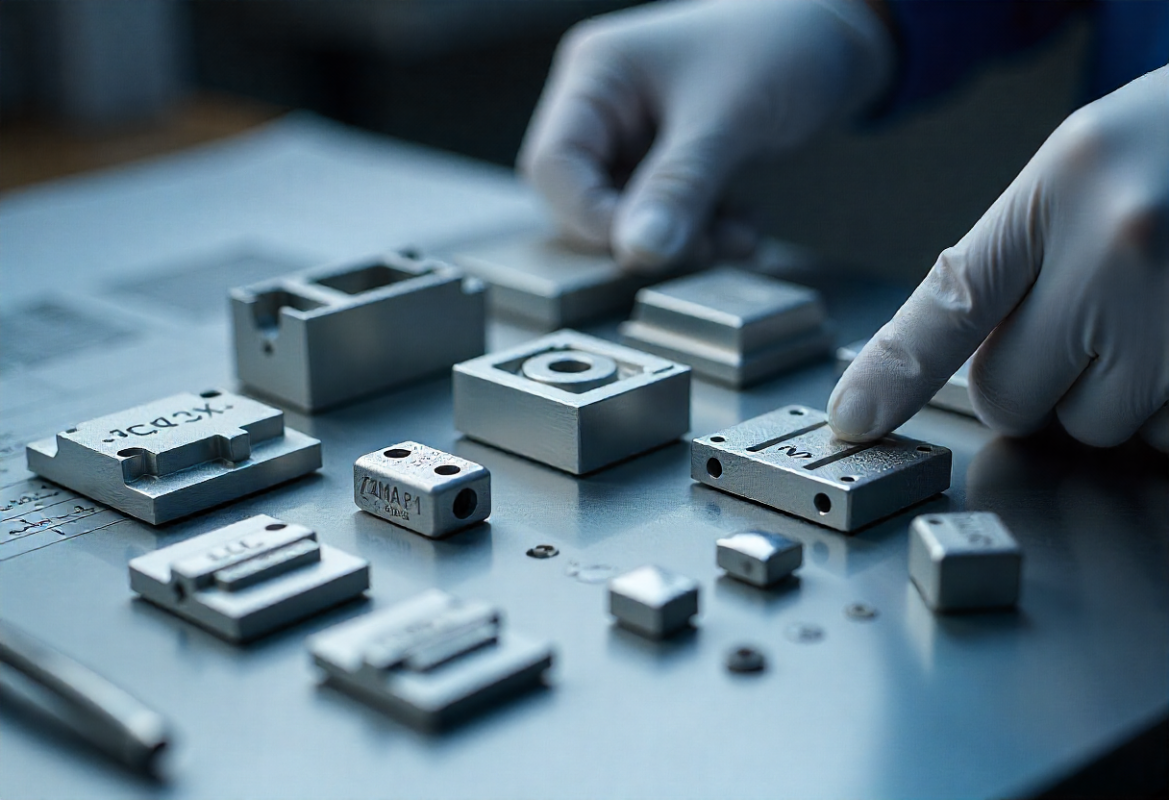

Die Casting Parts (Aluminum & Zinc) Precision Castings with CNC Finish

We produce high‑quality aluminum and zinc die cast components engineered for strength, dimensional accuracy and surface finish. Our services include die design, vacuum and pressure casting, porosity reduction, secondary CNC machining, and full finishing — ideal for automotive, power electronics, lighting, and industrial hardware.

- Aluminum (ADC12, A380, A356) and Zinc (Zamak 3/5/8) alloys

- Vacuum/low‑pressure casting for low porosity and high integrity

- Tooling, secondary CNC machining, plating, anodize, and assembly

Aluminum Castings

Vacuum & Low‑Pressure

CNC Finishing

What We Make

Aluminum Die Cast Housings & Enclosures

Zinc Die Cast Components

Custom Pressure‑Bearing & Structural Parts

Alloys & Material Selection

Material guidance

Die Casting Processes

Process options

- High‑pressure cold‑chamber die casting (aluminum)

- Hot‑chamber die casting (zinc alloys)

- Vacuum/low‑pressure casting to reduce trapped gas

- Controlled fill and controlled solidification for directional feed

Tooling & Die Engineering

Tool life & cavities

Secondary Machining & Assembly

Assembly services

Surface Finishing & Coatings

Functional coatings

Typical Specifications & Design Guidelines

Design guidance to reduce porosity, facilitate fill and minimize shrink: uniform wall thickness, proper rib/ boss design, and adequate gating/venting strategies.

Wall Thickness

1.5 — 6.0 mm typical (dependent on part size & alloy)

Draft Angles

0.5° — 2.0° recommended for vertical faces

Shrink

Aluminum: ~1.2% — 1.5%; Zinc: ~0.4% — 0.6% (design for shrink during tooling)

Size Range

Small precision parts to large housings; press size and shot weight determine part max envelope

| Parameter | Range | Notes |

|---|---|---|

| Alloys | ADC12, A380, A356 (Al); Zamak 3/5/8 (Zn) | Selected by strength, thermal, and finishing needs |

| Typical tolerances | ±0.15 mm — ±0.5 mm (post-cast); ±0.02 mm — ±0.05 mm (after CNC finishing) | Tolerances depend on feature and secondary machining |

| Porosity control | Vacuum/low-pressure casting | Recommended for pressure bearings and structural parts |

| Lead time | Tooling 6–14 weeks; prototypes shorter with soft tooling | Depends on complexity & cavity count |

Quality, Inspection & Traceability

Non‑destructive testing

Applications

Automotive & EV

Powertrain housings, gearbox covers, sensor mounts and structural brackets with automotive quality controls.

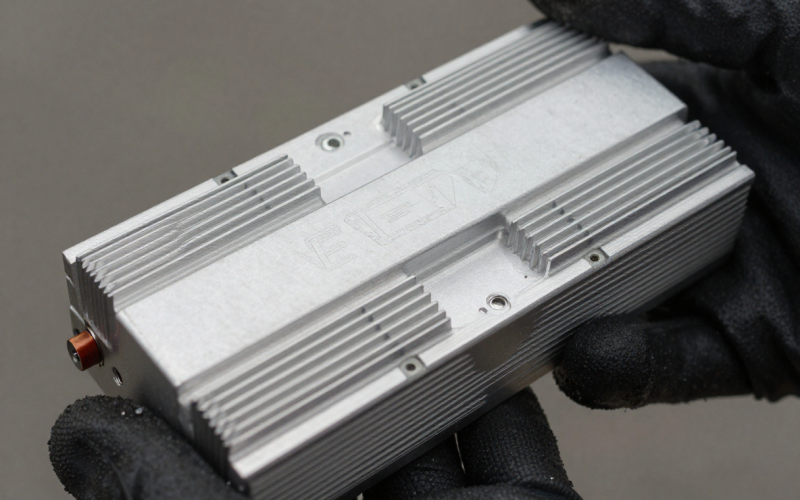

Power Electronics & Inverters

Thermal enclosures, busbar supports and conductive housings for heat dissipation and EMI control.

Lighting & Consumer Hardware

Die cast light housings, heatsink‑integrated parts and plated cosmetic trims.

Representative Projects

Aluminum Housing for EV Inverter