Automotive • Motorsport • EV Upgrade Components — High‑Performance Parts & Modules

We engineer and manufacture components and assemblies for OEM, motorsport and EV upgrade markets — including structural brackets, lightweight housings, thermal subsystems, electrical enclosures, and turnkey cooling modules. Our design for manufacturability approach ensures parts meet automotive durability, safety and performance targets.

- Lightweight structural parts and thermal management subsystems for EVs and power electronics

- Performance upgrades for motorsport — housings, mounts, brackets and airflow hardware

- Full NPI support: prototype, validation (EVT/DVT/PVT), PPAP/FAI and volume production

EV Thermal Subsystems

Die Cast Housings

Precision Machining

What We Do for Automotive, Motorsport & EV Upgrades

We deliver engineered components and assemblies that address vehicle-specific constraints — weight, thermal limits, vibration, ingress protection and serviceability. Typical deliverables include performance housings, thermal modules, structural brackets, custom connectors, busbars, and full electromechanical assemblies ready for integration into production or aftermarket kits.

Thermal Systems & Cooling Modules

Design and manufacture of liquid cold plates, vapor chambers and integrated cooling modules with pumps, manifolds and leak containment for EV power electronics.

Lightweight Structural Parts

Aluminum extrusions, forged brackets, die cast housings and CNC‑machined components optimized for stiffness‑to‑weight and crash or vibration loads.

Power Distribution & Electrical Components

Busbars, stamped power carriers, insulated housings, overmolded connectors and assemblies validated for current carrying capacity and thermal dissipation.

Finishing & Corrosion Protection

Anodize, powder coat, plating, conformal coatings and sealing to meet automotive environmental requirements (salt spray, humidity, UV).

Prototype → Validation → Production (NPI)

Our NPI flow is tailored for automotive timelines: quick-turn prototypes (CNC, soft tooling), EVT/DVT/PVT validation with test plans, PPAP/FAI packaging and controlled ramp to production. We provide DFMEA/PFMEA collaboration and process window documentation to reduce launch risk.

Typical deliverables

Prototype parts, test reports, material certifications, Cpk & capability studies, PPAP/FAI documentation and production control plans.

Supply Chain & Fulfillment

We support kitting, serialization, DDP shipping, VMI and warehousing options (including Dallas USA hub) for OEM and aftermarket programs to ensure reliable global fulfillment and aftersales support.

Logistics & packaging

Shock‑tested packaging, JIT delivery, customs support and local stocking to meet OEM rollouts and motorsport service needs.

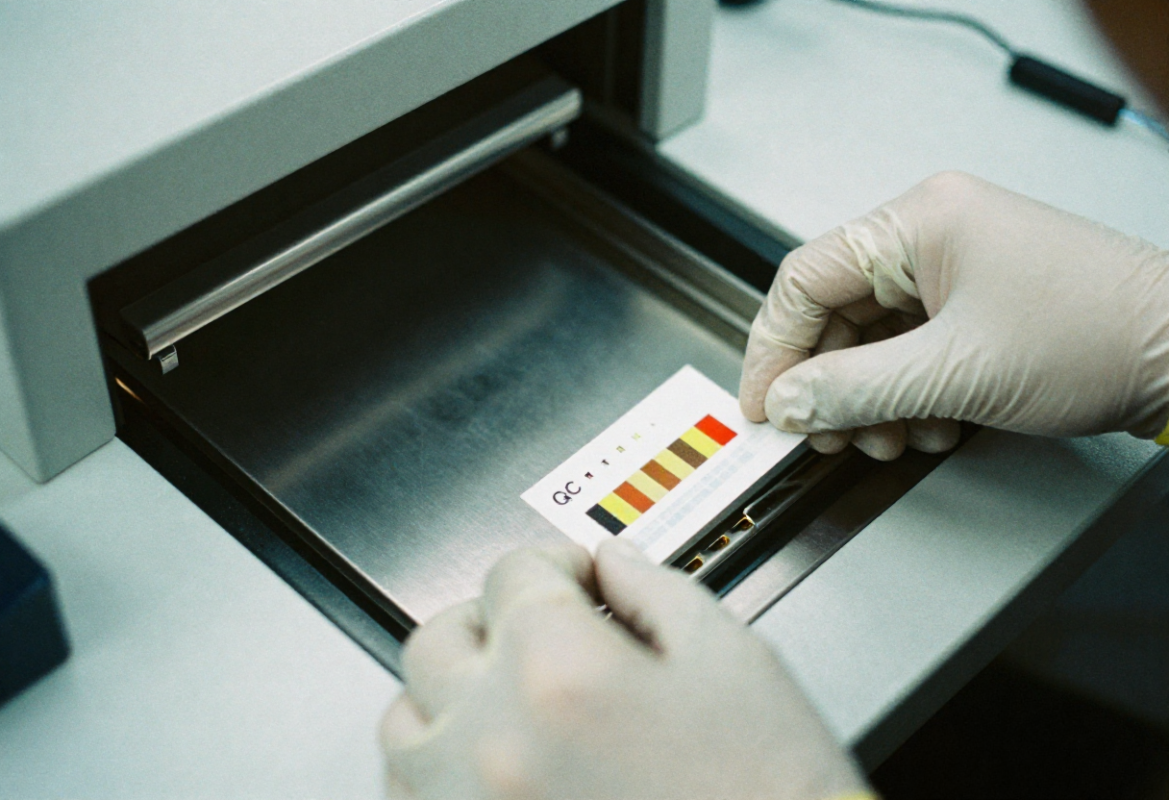

Materials, Validation & Regulatory

Materials chosen for crashworthiness, corrosion resistance and thermal conduction. We validate parts for vibration, thermal cycling, salt spray, ingress protection (IP), and EMI/EMC as applicable for modules containing electronics.

Testing & quality

CMM, dynamic vibration, environmental chambers, thermal cycling, leak testing for fluid systems, and electrical safety/EMC testing for modules with electronics.

Representative Specifications

Representative ranges — we tailor exact specifications during engineering based on vehicle integration, power budgets and lifecycle expectations.

Operating Temp

-40 °C to +125 °C typical; extended ranges for power electronics.

IP Rating

IP54 — IP69K options depending on enclosure sealing and connector choice.

Vibration

Random vibration per target vehicle spec (e.g., 8–2000 Hz) and shock per OEM test profiles.

Thermal Resistance

Module-level Rθ dependent on cooling architecture; we supply CFD and measured ΔT maps.

| Parameter | Typical Range | Notes |

|---|---|---|

| Materials | Aluminum, HS steel, stainless, titanium, engineering plastics | Select per strength, weight and thermal needs |

| Fasteners & sealing | IP-rated connectors, O-rings, RTV, structural adhesives | Serviceability vs permanent sealing tradeoffs |

| Lead times | Prototype: days–3 weeks • NPI: 6–16+ weeks | Depends on tooling, validation and certification needs |

| Quality & compliance | ISO 9001; PPAP/FAI, material MTRs, traceability | Industry-specific documentation available |

Applications

EV Inverters & Power Electronics

Cold plates, vapor chambers, die cast housings and integrated cooling modules for inverter and DC‑DC systems.

Battery Thermal Management

Cooling plates, manifolds and leak‑managed assemblies for module and pack thermal control.

Motorsport & Performance Upgrades

Lightweight brackets, airflow components, heat shields and ruggedized housings for track environments.

Representative Projects

EV Inverter Cooling Module

Integrated liquid cooling module with FSW cold plate, embedded vapor chamber and redundant pump architecture — passed thermal, leak and vibration qualification for automotive release.

Lightweight Forged Bracket for Suspension

Closed‑die forged aluminum bracket with CNC finish and surface treatment that reduced weight by 18% while meeting fatigue life targets for motorsport use.

Frequently Asked Questions

Can you support PPAP and automotive supplier audits?

Yes — we prepare PPAP/FAI packages, capability studies, material certifications and support supplier audits to meet OEM procurement requirements.

How do you validate thermal solutions for EVs?

We use CFD correlation, prototype thermal mapping, transient tests and system-level integration tests to validate Rθ, transient response and coolant/pressure behavior under vehicle conditions.

Do you offer on‑vehicle installation & service kits for aftermarket upgrades?

Yes — we provide installation kits with harnesses, mounting brackets and serviceable connectors, plus repair/spare part programs for aftermarket dealers and motorsport teams.

Start Your Automotive or EV Project

Upload your CAD, power and integration targets and tell us vehicle constraints. We’ll return manufacturability & thermal feasibility feedback, recommended architectures and a prototype plan — typically within 24 business hours.