Surface Treatment & Special Coatings — Functional & Cosmetic Finishes

We apply and qualify surface treatments ranging from standard anodize and plating to advanced PVD, thermal spray and functional topcoats (EMI, thermal, hydrophobic, anti‑fingerprint, anti‑microbial). Services include pretreat, in‑process controls, test qualification and production scaling with environmental and regulatory compliance.

What we provide

Finish compatibility guidance, sample panels, environmental/abrasion testing, production racks, masking, and post‑finish machining allowances for critical datums.

Finish Categories & Typical Uses

Conversion Coatings

Anodize, chromate conversion, passivation for corrosion protection and paint adhesion (aluminum, steel, zinc).

Plating & Metallization

Electroless nickel, copper, chrome, zinc plating and PVD for aesthetics, wear and conductivity.

Powder & Wet Paint

Durable color/topcoats with texture control; e‑coat for complex coverage prior to topcoat.

PVD & Hard Coatings

Thin, wear‑resistant coatings (TiN, DLC) for sliding surfaces and premium decorative finishes.

Thermal Spray

Ceramic/metal sprays for thermal barriers, high wear and high emissivity applications.

Functional Topcoats

Anti‑fingerprint, oleophobic, antimicrobial, EMI conductive coatings and low‑friction coatings tailored to system needs.

Process Steps & Pretreatment

Proper pretreatment is critical for adhesion and long‑term performance. Our workflow covers cleaning, etch/abrasion, conversion coat, electroless seed layers (for plastics), and controlled bake/seal steps prior to topcoat.

Pretreatment

- Degrease, alkaline clean and micro‑etch

- Conversion coatings (iridite, chromate-free chemistries)

- Electroless nickel seed for non-conductive substrates before plating

Functional & Performance Coatings

Functional coatings are specified by measurable properties — e.g., emissivity, surface resistivity, contact angle, Taber cycles to failure or log reduction for antimicrobial performance. We select and validate coatings to meet quantitative targets and service life.

Thermal Emissivity Coatings

High‑emissivity paints and ceramic sprays to improve heat rejection from housings and heat spreaders.

EMI / Conductive Coatings

Conductive paints and plated housings for shielding; validated attenuation across targeted frequency bands.

Hydrophobic & Anti‑Fingerprint

Oleophobic treatments and hard topcoats to improve perceived quality and reduce cleaning cycles.

Testing, Qualification & Standards

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.We validate finishes using industry standards and custom test cycles. Tests are selected to reflect real use and may include corrosion, abrasion, adhesion, UV/weathering, emissivity, EMI shielding and antimicrobial efficacy testing.

| Test | Purpose | Standard / Method |

|---|---|---|

| Salt Spray | Corrosion resistance | ASTM B117 / cyclic corrosion |

| Adhesion | Coating adhesion | ASTM D3359 (cross‑cut/tape) |

| Abrasion | Wear resistance | Taber ASTM D4060 |

| UV / Weathering | Color & gloss retention | ASTM G154 / G155 |

| EMI Shielding | Shielding attenuation | ISO/IEC EMC test methods |

| Hydrophobicity | Contact angle | Contact angle measurement |

Design for Finishing (DFF) — Practical Guidance

- Identify critical datums and sealing faces to be masked or final machined after finishing

- Specify finish thickness targets and tolerances (anodize µm, powder coat µm, plating µm)

- Group parts with similar chemistry and color to avoid cross‑contamination during production

- Provide sample panels early for color/texture approval and adhesion testing

| Finish | Typical Thickness | Allowance Guidance |

|---|---|---|

| Anodize | 5–25 µm | Allow 0.05–0.2 mm per surface where interference fits exist |

| Powder Coat | 40–120 µm | Allow 0.1–0.3 mm for gasket/fit zones |

| Plating (Ni/Cr) | 5–30 µm | Specify post-plate machining for critical datums |

| PVD / DLC | 0.1–5 µm | Negligible thickness but specify adhesion & scratch requirements |

Environmental, Safety & Regulatory Considerations

Finishing chemistries and waste streams are regulated. We manage RoHS/REACH compliance, hazardous waste treatment, restricted substances, and documentation for supply chains. Options for low‑VOC and greener chemistries are available where feasible.

- RoHS/REACH declarations and material certificates

- Wastewater treatment and solvent recovery for plating/paint lines

- Substance screening and supplier attestations for regulated sectors

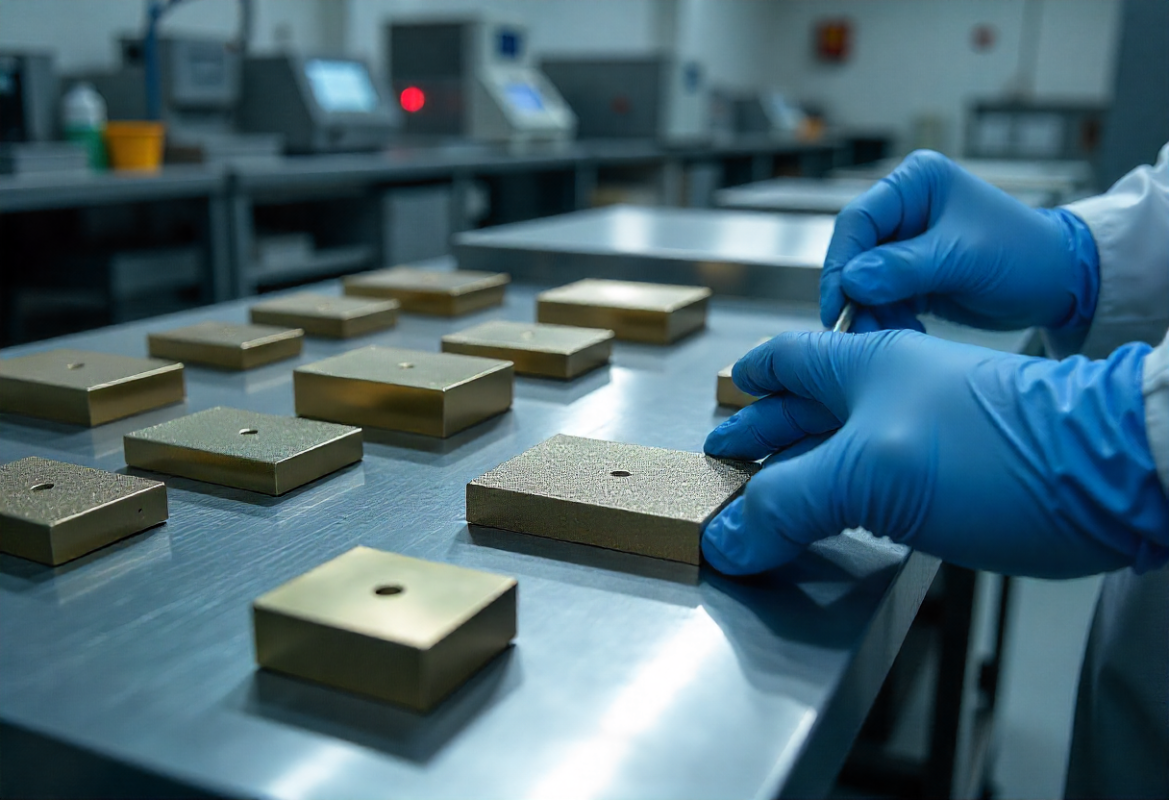

Sample Panels, Color Matching & Production Scaling

We produce finish sample panels and lab reports for customer sign‑off prior to scaling. Pilot racks and production run validations ensure process repeatability and color/texture consistency across batches.

Deliverables

- Sample panels with gloss & color metrics

- Qualification report with test data and process window

- Production ramp plan and SPC control charts

Representative Projects

Electroless Nickel + PVD for Consumer Trim

Electroless nickel undercoat with PVD topcoat delivered premium chrome‑like finish with superior scratch resistance and controlled corrosion performance.

High‑Emissivity Ceramic Coating for Power Modules

Thermal spray ceramic applied to heat spreaders increased emissivity and reduced operating junction temperatures; qualified with thermal mapping and 1000‑hour thermal cycling

Frequently Asked Questions

Can you plate plastic parts?

Yes — many plastics can be plated after etch and conductive seed layers (electroless nickel). Confirm polymer grade and necessary pre‑treatment early; some resins require specialty chemistries.

How do finishes affect recycling?

Heavy multi‑layer finishes can complicate recycling. Where recyclability matters, prefer finishes that are compatible with metal recycling (e.g., anodize) and document material/finish composition for downstream processors.

What finish is best for marine environments?

Duplex systems (e‑coat + powder/topcoat) or electroless nickel with appropriate sealants are commonly used. Extended cyclic corrosion testing and sacrificial coating strategies are recommended for maritime use.

Specify Your Finish

Upload part CAD, substrate, exposure environment and cosmetic goals. We’ll recommend finishes, process windows, sample panels and a test plan — typically within 24 business hours.