Injection Molding — Prototype to High‑Volume Production

A turnkey regional warehouse in Dallas to accelerate delivery across North America, reduce transit damage and support returns, kitting, lig

Comprehensive injection molding services: rapid prototype molds, hardened production tooling, hot runner and valve gate systems, multi‑cavity strategies, insert/overmold capabilities and process validation (FAI/PPAP). We partner early to optimize part design, cycle time and total cost of ownership.

Typical Offerings

Prototype aluminum molds • Hardened steel production molds (P20/H13) • Hot runner & valve gate integration • Multi‑cavity and family molds • Overmold/insert tooling • Tryout & FAI packages

Engineering, Fixturing & DFM for Machining

Prototype Molds (Aluminum / Soft Tooling)

Fast, low‑cost tools for design validation, cosmetic checks and functional testing. Ideal for EVT/DVT phase, short pilot runs and pre‑production samples.

- Lead time: 1–4 weeks

- Lower shot life; cost effective for early validation

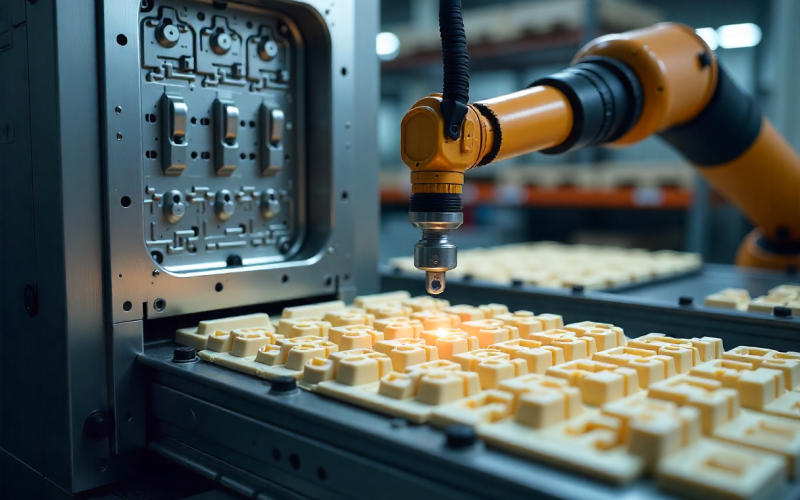

Production Molds (Hardened Steel)

Designed for repeatability, long shot life and tighter cosmetic control. Options include hot runner systems, valve gates and multi‑cavity configurations.

- Lead time: 6–16+ weeks (complex tools may take longer)

- Includes polishing, heat treat, and hot runner commissioning

Hot Runner, Valve Gate & Runner Strategy

We select runner strategies based on part geometry, material and volume economics. Hot runners reduce material waste and cycle time for higher volumes. Valve gates provide precise gate control and cosmetic benefits for family or high‑appearance molds.

Hot Runner

Lower scrap, faster cycles, improved balancing for multi‑cavity parts.Valve Gate

Precise gate control, clean gate vestige, useful in family molds and cosmetic surfaces.

Cold Runner

Lower tool cost for low volumes or highly filled materials where hot runner maintenance is not ideal.Materials & Processing Considerations

We mold a wide range of thermoplastics and elastomers. Material choice affects gate design, cooling, tool wear and finish compatibility.

Practical initiatives

Engineering Plastics

PA, POM, PBT, PC, ABS/PC blends for structural and cosmetic parts.

High‑Performance

PEEK, PEI for high temp and chemical environments; requires hardened tooling and high temp processing.

TPE & Elastomers

TPU, TPE for soft touch; LSR for medical/food contact (see elastomer capabilities).

Notes

- Glass/mineral filled grades increase tool wear and may require coated inserts (TiCN, TiAlN)

- Hygroscopic materials (nylon) require drying before molding to avoid voids

- Flammability and regulatory (UL, FDA) requirements should be specified early

Tool Tryout, First Article & Process Validation

Tryout includes sample runs, dimensional CMM, cosmetic inspection, process window documentation and FAI/PPAP deliverables. We provide SPC plans, recommended checkpoints and operator setup sheets to ensure reproducible production.

Deliverables

- First Article Inspection (FAI) including CMM reports

- Process window (clamp force, temps, cycle time, cooling)

- Sample galleries, cosmetic sign‑off and production setup sheets

Design for Injection Molding (DFM) Guidance

Good DFM reduces cost, cycle time and scrap. Our team provides practical recommendations to improve moldability and reduce downstream operations.

| Item | Recommendation | Notes |

|---|---|---|

| Wall thickness | Uniform where possible | Minimize thick sections to avoid sink; follow resin datasheet |

| Draft | 0.5°–2° | Increase for textured surfaces |

| Ribs & bosses | Use ribs for stiffness; bosses ≤0.6× wall | Include proper radius to avoid stress risers |

| Gate | Locate to balance fill and hide weld lines | CAE moldflow helps optimize |

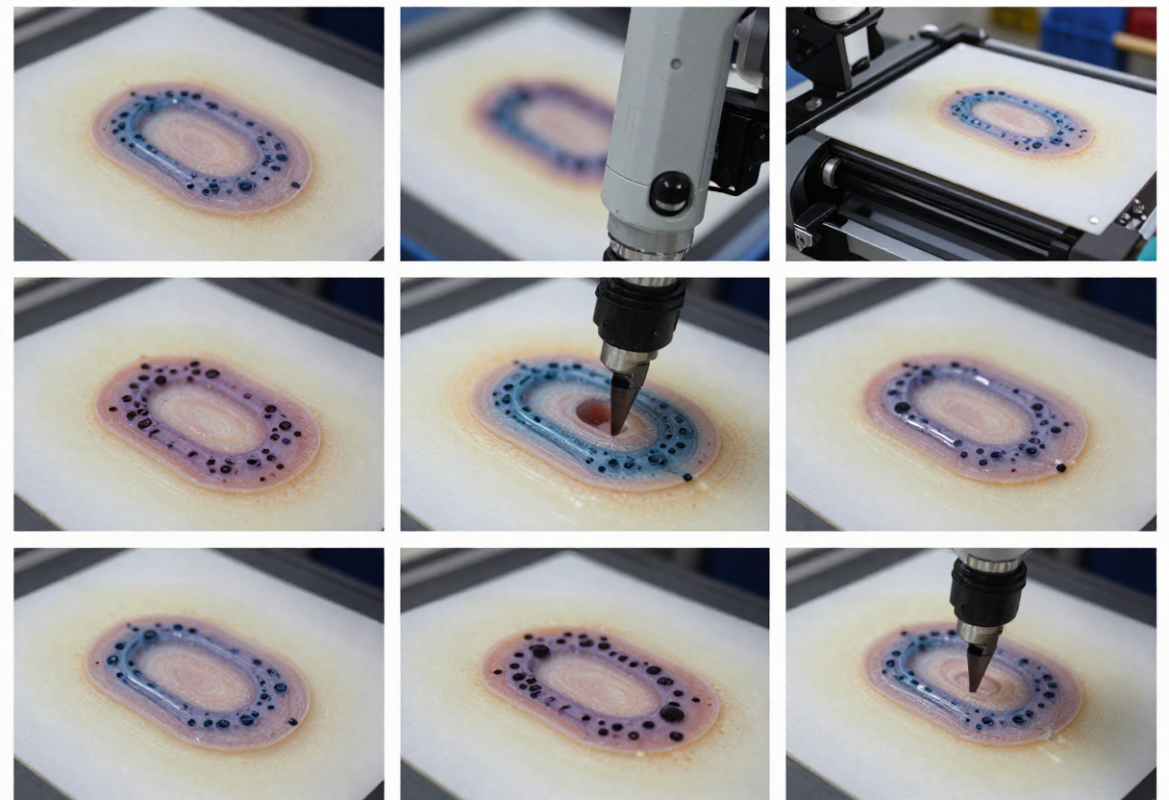

Overmolding, Insert Molding & Multi‑Shot

We design tools for insert molding, two‑shot and multi‑material molding to integrate seals, soft grips and overmolded features. Tooling includes insert stations, robotic transfer or indexed platens for synchronizing shots.

- Insert retention features and fixturing to prevent movement during molding

- Material compatibility checks and adhesion strategies (primers or mechanical interlocks)

- Automation for insert placement reduces cycle time and rejects

Tool Maintenance & Lifecycle Support

Planned PM, spare cores/inserts, EDM rework, recoating and emergency repair lanes protect production uptime. We track shot counts and recommend PM intervals tied to material abrasiveness and process demands.

Services

- PM schedules, polish cycles and dimensional checks

- EDM rework, insert fabrication and recoating (TiN/TiCN)

- On‑site support during ramp and spare tooling strategies

Representative Specs & Lead Times

| Item | Typical Lead Time | Notes |

|---|---|---|

| Aluminum prototype mold | 1–4 weeks | Quick samples, limited shot life |

| Hardened steel production mold | 6–16+ weeks | Heat treat, EDM and polishing add time |

| Multi‑cavity hot runner mold | 8–18 weeks | Hot runner balancing and commissioning required |

| Two‑shot / overmold tooling | 8–20 weeks | Complex synchronization and robotic transfer may be needed |

Secondary Operations & Assembly

We provide trimming, ultrasonic welding, heat staking, ultrasonic welding, pad/silk printing, plating preparation, adhesive bonding, subassembly, and final box‑build with testing. We also support ganging/fixturing for efficient post‑process operations.

Testing, Validation & Compliance

We support dimensional CMM, cosmetic inspection, mechanical testing, flammability, UL/IEC coordination, and FAI/PPAP documentation for production release. For regulated markets we provide material traceability and certificates of conformity.

Representative Projects

High‑Volume Consumer Housing

Multi‑cavity hot runner mold with overmolded soft grips, integrated inserts and automated pick‑and‑place — scaled to 500k+ units/year.

Medical LSR Port with Overmold

Two‑shot overmold combining rigid PC carrier and LSR sealing feature produced in cleanroom cells with full lot traceability.

Frequently Asked Questions

How do I decide between prototype and production tooling?

Use prototype tooling for early validation and low‑volume needs. Move to hardened production tooling when expected annual volumes justify the higher upfront cost and you need repeatability and long shot life.

Can you handle overmolding and insert molding in the same tool?

Yes — we design and build overmold and insert stations into tools and provide robotic automation or indexed platens for precise multi‑shot sequences.

What documentation is provided after tryout?

We deliver FAI/PPAP packages, process windows, clamp/cycle records, sample galleries, SPC checkpoints and recommended PM schedules for the tool.

Start Your Injection Mold Project

Upload CAD, material selection, expected volumes and cosmetic requirements. We’ll return a tooling recommendation, estimated lead time and cost amortization model — typically within 24 business hours.