Die Casting Aluminum & Zinc Pressure Die Casting

High‑volume die casting capabilities for aluminum and zinc alloys: cold‑chamber aluminum, hot‑chamber zinc, vacuum/low‑pressure options, tooling design, machining and finish integration. We support programs from prototype castings through full production, with robust inspection and NPI controls for critical applications.

Quick alloy map

- A356 — heat‑treatable aluminum for structural castings

- ADC12 / A380 — common die casting alloys with good fluidity and cosmetic finish

- Zamak — high detail zinc die cast for decorative and plated parts

Die Casting Processes & Technology

Cold‑Chamber Aluminum Die Casting

Used for aluminum alloys due to higher melt temperatures. Molten metal is ladled into the injection chamber and shot into the die. Suitable for structural parts, housings and thermal components where aluminum’s strength and thermal conductivity are beneficial.

Hot‑Chamber Zinc Die Casting

Hot‑chamber machines have the injection mechanism submerged in molten zinc — fast cycle times and excellent dimensional control. Zinc offers superior fluidity and is ideal for thin‑wall, high‑detail parts and plated decorative trims.

Vacuum / Low‑Pressure & Squeeze Casting

Vacuum-assisted and low‑pressure die casting reduce entrapped gases and shrink porosity in critical parts. Squeeze casting combines pressure die casting with applied counterpressure during solidification to improve density and mechanical properties for structural applications.

Tooling & Design Considerations

Elastomer tooling focuses on cavity finish, venting and thermal control. LSR cavities are typically stainless with mirror polish where optics or cosmetics are required. HCR (solid) silicone and rubber tooling uses tool steel inserts with proper vent/runner design and heaters.

Cavity Finish

Mirror polish for optical/cosmetic zones; textured finishes for grip areas.Venting & Gas Traps

Micro‑venting design to avoid pinholes and air entrapment; gas trap placement critical for LSR.

Heaters & Thermocouple Control

Multiple zones and precise control for uniform cure and repeatability.Alloy Guidance & Typical Applications

Heat‑treatable, good fatigue & thermal properties — common in structural castings and housings requiring post‑machining.

ADC12 / A380

Excellent fluidity & surface finish for high‑volume die casting; commonly used for consumer and industrial housings.

Zamak (Zinc)

Superior detail & plating base — ideal for decorative trim, connectors and complex geometry with thin walls.

Material considerations

- Aluminum alloys may require vacuum casting and heat treatment for high‑integrity parts.

- Zinc excels at thin walls and fine details but has lower high‑temperature strength than aluminum.

- Specify mechanical property targets (yield, tensile, elongation) and we’ll recommend alloy/process to meet them.

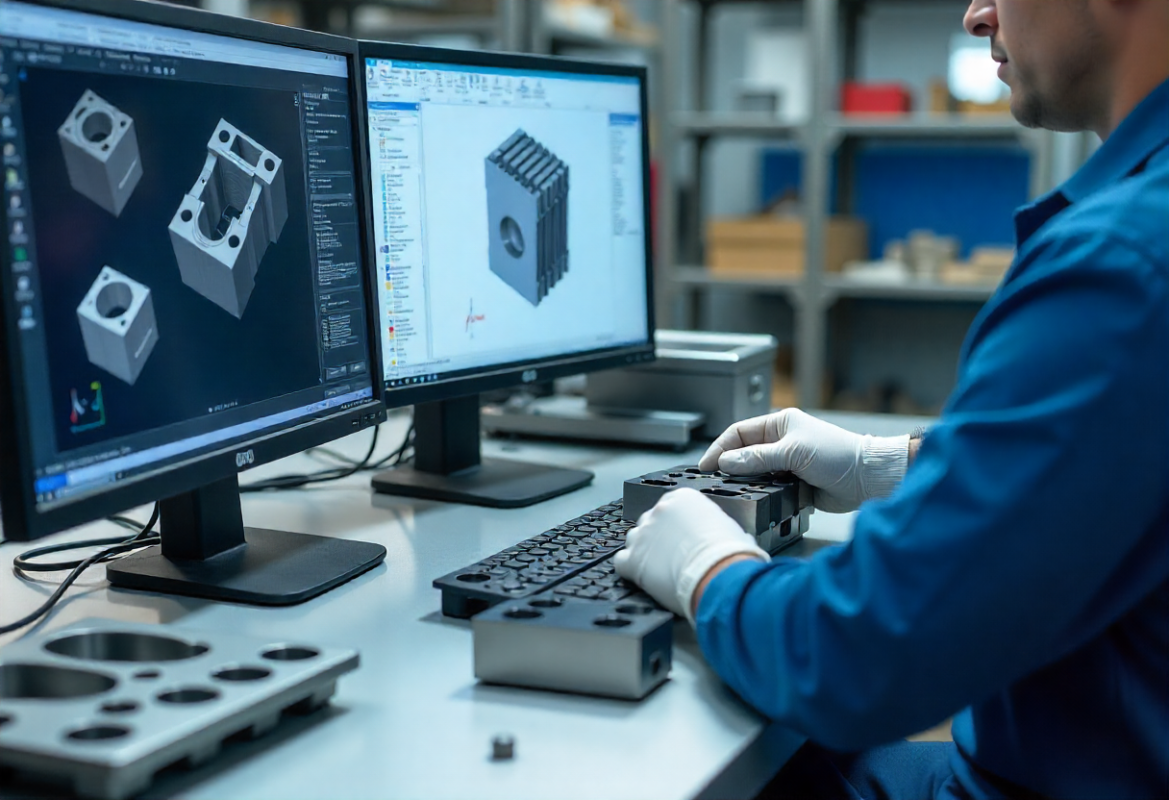

Tooling Design, Tryout & Maintenance

Die design balances fill, solidification, venting and ejection. We design with corrosion‑resistant steel, replaceable inserts, conformal cooling where applicable, and provisions for venting and vacuum ports. Tool tryout includes sample casting runs, die adjustments and documented process windows.

Tool life & maintenance

- High‑volume steel dies with replaceable wear inserts extend service life

- Regular die maintenance: polishing, vent rework, ejector/bushing replacement and shot count tracking

- Emergency lanes for rapid insert repair and EDM rework reduce downtime

Filling, Porosity Control & Quality Assurance

Porosity control is key for structural die castings. Techniques: optimized gating, controlled fill speed, vacuum/low‑pressure casting, melt degassing, and thermal controls. Qualification uses CT/X‑ray, ultrasonic and mechanical testing to ensure internal integrity and fatigue performance.

NDT & Inspection

- X‑ray / CT for porosity mapping and internal defects

- Ultrasonic flaw detection for thicker sections

- CMM and optical scanning for dimensional verification

Process controls

- Melt chemistry monitoring and MTR linkage

- Shot‑by‑shot data logging, SPC and capability studies (Cpk)

- FAI/PPAP packages for production release

Post‑Cast CNC Finishing & Secondary Operations

Die castings frequently require machining of sealing faces, threaded holes, and critical datums. We provide fixture design for machining, CNC finishing, tapping, surface treatment preparation, heat treatment (T6 aging for some alloys) and assembly operations.

Typical secondary ops

- CNC finish machining of critical datums and sealing faces

- Heat treatment and solution aging (where applicable)

- Plating, painting, anodize conversion (for aluminum‑machined surfaces) and assembly

Finishing Options & Decorative Treatments

We integrate finishing workflows to meet cosmetic and corrosion requirements: electroless nickel, chrome plating (on appropriate substrates), powder/wet painting, powder coat over pre‑treat, and mechanical polishing. Zinc is an excellent plating base for decorative chrome‑like finishes.

Aluminum finishing

Cast aluminum may be machined then anodized (where alloy compatibility allows) or painted with appropriate pre‑treat. Consult early for anodize compatibility with die‑cast alloys.

Zinc finishing

Zinc die castings plate exceptionally well (Ni/Cu/Cr sequences) and support high‑quality decorative trims and corrosion resistance with lower cost.

Representative Lead Times & Tooling

Lead times depend on tooling type and material. Prototype compression/transfer molds: 2–4 weeks. Hardened LSR production molds: 6–12+ weeks. Specialty medical compounds may have longer lead times and MOQs — plan accordingly during NPI.

| Item | Typical Lead Time | Notes |

|---|---|---|

| Prototype castings (soft tool / EDM insert) | 2–6 weeks | Validation parts for fit/function |

| Hardened production die (steel) | 8–20+ weeks | Depends on cavities, inserts & heat treat |

| Tool refurb / insert fabrication | 1–4 weeks | EDM, replating and polishing scope dependent |

| Initial production run & validation | 2–6 weeks after tool ready | Includes NDT, FAI and process window |

Representative Projects

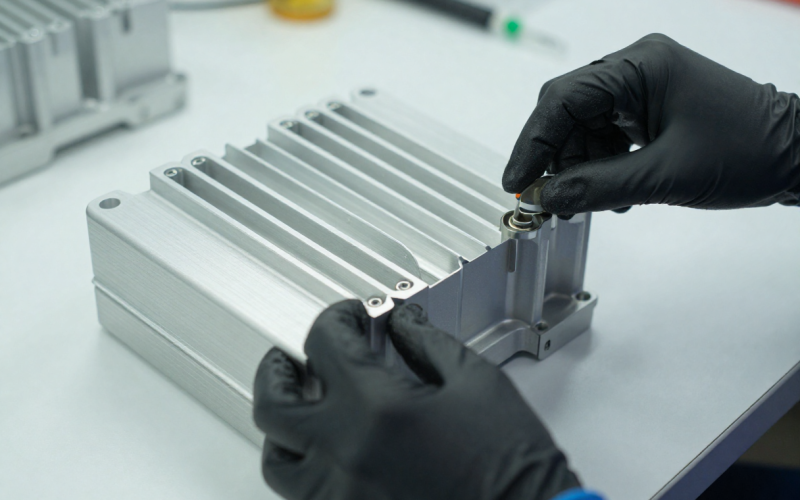

Aluminum Inverter Housing (Vacuum Die Cast)

Vacuum-assisted cold‑chamber casting with A356 alloy, CT verification for porosity, CNC finish of sealing faces and T6 aging for improved mechanical properties.

Zinc Decorative Trim (Plated)

Hot‑chamber zinc die cast trim with electroless nickel and PVD finish for premium appearance and durability at scale.

Frequently Asked Questions

How do you handle thin‑wall designs?

Die casting excels at thin walls; we optimize gate location, flow and fill velocity to avoid cold‑shuts. Zinc is particularly good for very thin walls due to high fluidity; aluminum thin‑wall parts may require vacuum/optimized venting.

Can cast parts be heat treated?

Yes — certain aluminum alloys (like A356) can be solution treated and aged (T6) to achieve improved strength. Heat treatment is planned for distortion control and machining allowances.

What quality documentation do you provide?

MTRs, FAI/PPAP packages, CMM reports, NDT (X‑ray/CT) reports, SPC data and process window documentation are provided for production release and traceability.

Start Your Die Casting Project

Upload part CAD, target volumes, mechanical requirements and preferred alloy. We will return a recommended casting process, tooling concept, expected lead times and a porosity mitigation plan — typically within 24 business hours.