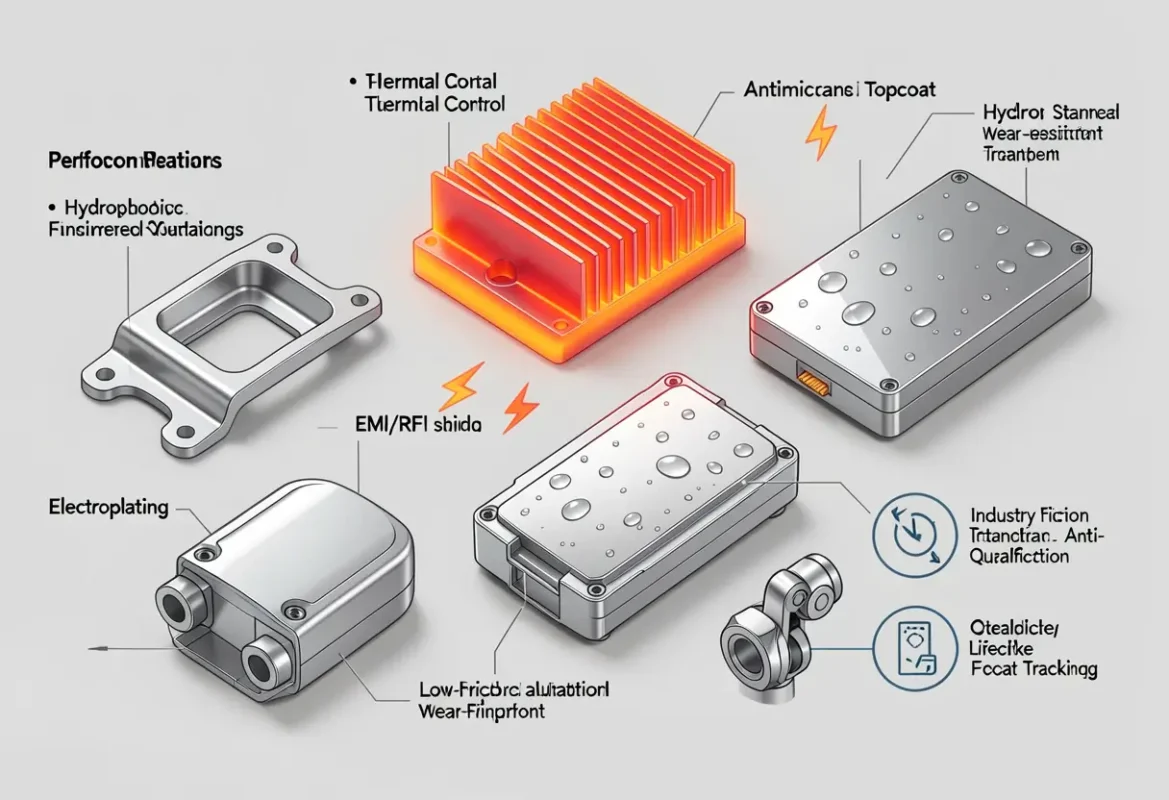

Performance Finishing Functional Coatings for Durability & System Performance

Functional coatings and engineered surface treatments that add measurable system value: corrosion protection, thermal control, EMI/RFI shielding, hydrophobicity, anti‑fingerprint, anti‑microbial action, wear reduction, and low‑friction surfaces. We specify, apply, and validate coatings for demanding environments and regulated industries.

- System‑level finishes selected for measured performance, not just appearance

- Matched application method and substrate: PVD, thermal spray, electro/ electroless plating, powder/wet coatings, plasma treatments

- Tested & qualified per industry standards with lifecycle and recoat strategies

What Is Performance Finishing?

Key Coating Families & Typical Uses

Corrosion‑Resistant Systems

Thermal Control Coatings

EMI / Conductive Coatings

Anti‑Fingerprint / Oleophobic

Anti‑Microbial & Hygiene

Wear & Low‑Friction Coatings

Application Methods & When To Use Them

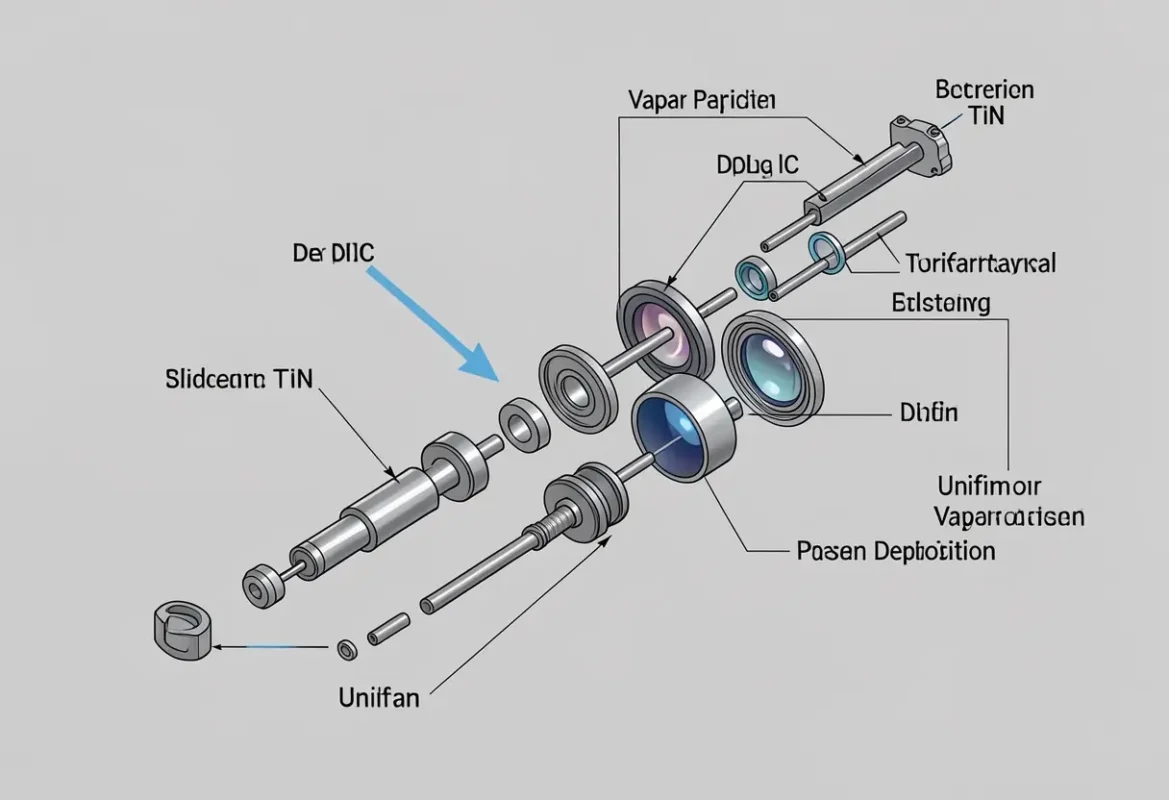

PVD / CVD / DLC

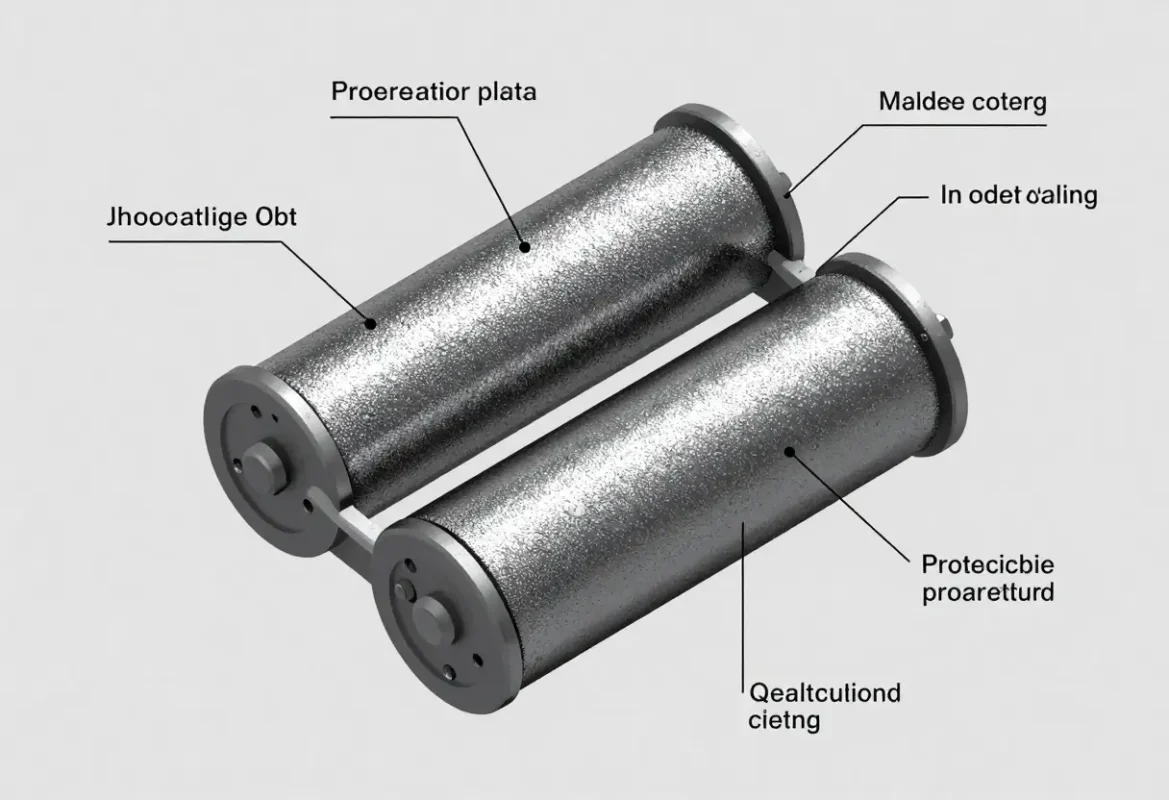

Thermal Spray & Plasma Spray

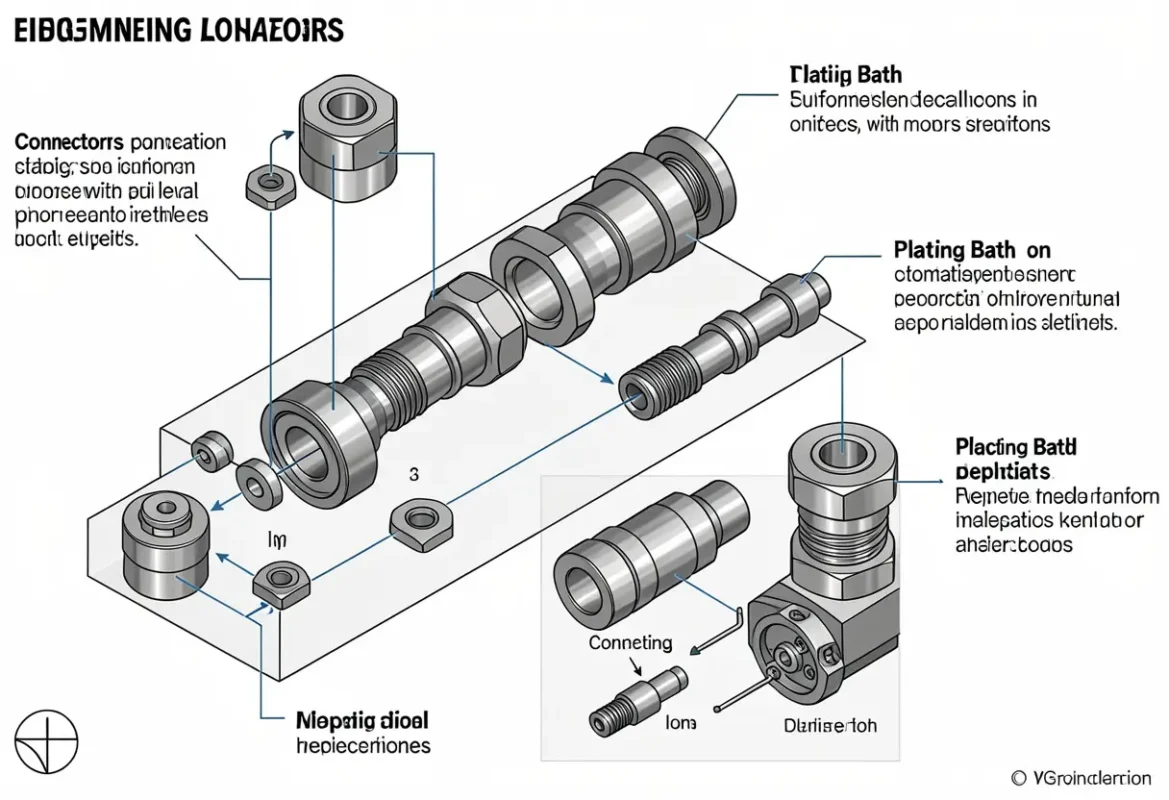

Electroless / Electro Plating

Spray / Dip / E‑Coat & Powder

Liquid & Sol‑Gel Hydrophobic / Oleophobic Treatments

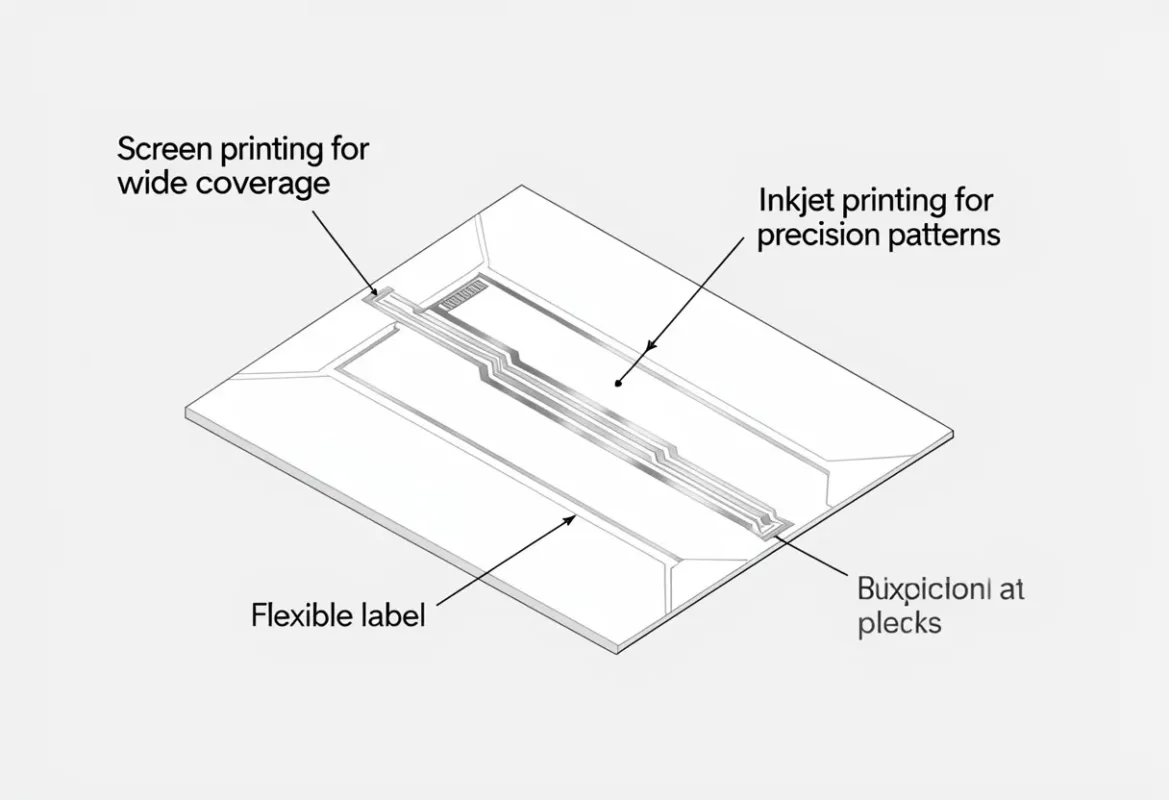

Conductive Inks & Printed Coatings

Substrate Compatibility & Pre‑Treatment

Performance coatings require appropriate substrate prep: conversion coats for aluminum, phosphate/electrocleaning for steels, plasma/etch for plastics, or conductive seed layers for plating plastics. Adhesion, thermal expansion and galvanic compatibility must be validated.

Aluminum

Anodize or conversion + suitable primers before topcoat; PVD possible on plated or conductive underlayers.

Steel

E‑coat or galvanize + topcoat recommended for severe corrosion; plating requires pretreat.

Plastics

Require etch/primer and often electroless nickel for plating or functional metal layers.

Performance Metrics, Testing & Qualification

We validate functional coatings with quantitative tests tied to requirements. Typical acceptance criteria are specified up front and included in FAI/PPAP packages for production release.

| Property | Test / Standard | Typical Metric |

|---|---|---|

| Corrosion resistance | Salt spray ASTM B117, cyclic corrosion | Hours to substrate attack / blistering |

| Wear resistance | Taber abrasion ASTM D4060, reciprocating wear | Cycles to coating failure / mg loss |

| Adhesion | Cross‑cut/tape ASTM D3359, pull‑off ASTM D4541 | Rating or minimum peel strength |

| Hydrophobicity | Contact angle measurement | Water contact angle ° (e.g., >100°) |

| Surface resistivity / EMI | Surface resistivity ASTM D257, shielding attenuation | Surface Ω/sq; dB attenuation at freq. |

| Antimicrobial efficacy | ISO 22196 / ASTM E2180 | Log reduction vs control |

Design for Performance Finishing (DFP)

- Define functional targets (metric + acceptance criteria) up front — e.g., contact angle, Taber cycles, hours salt spray

- Specify masking zones (threads, sealing faces) and include assembly/fit allowances for coating thickness

- Group parts by finish to minimize rework and batch variability — avoid mixing incompatible chemistries in one line

- Consider reworkability and recoating strategies for service & repair

Allowance guidance

Account for coating thickness in tolerances: thin PVD/DLC (µm scale) vs powder/e‑coat (tens to hundreds µm). Specify post‑finish critical datums where necessary.

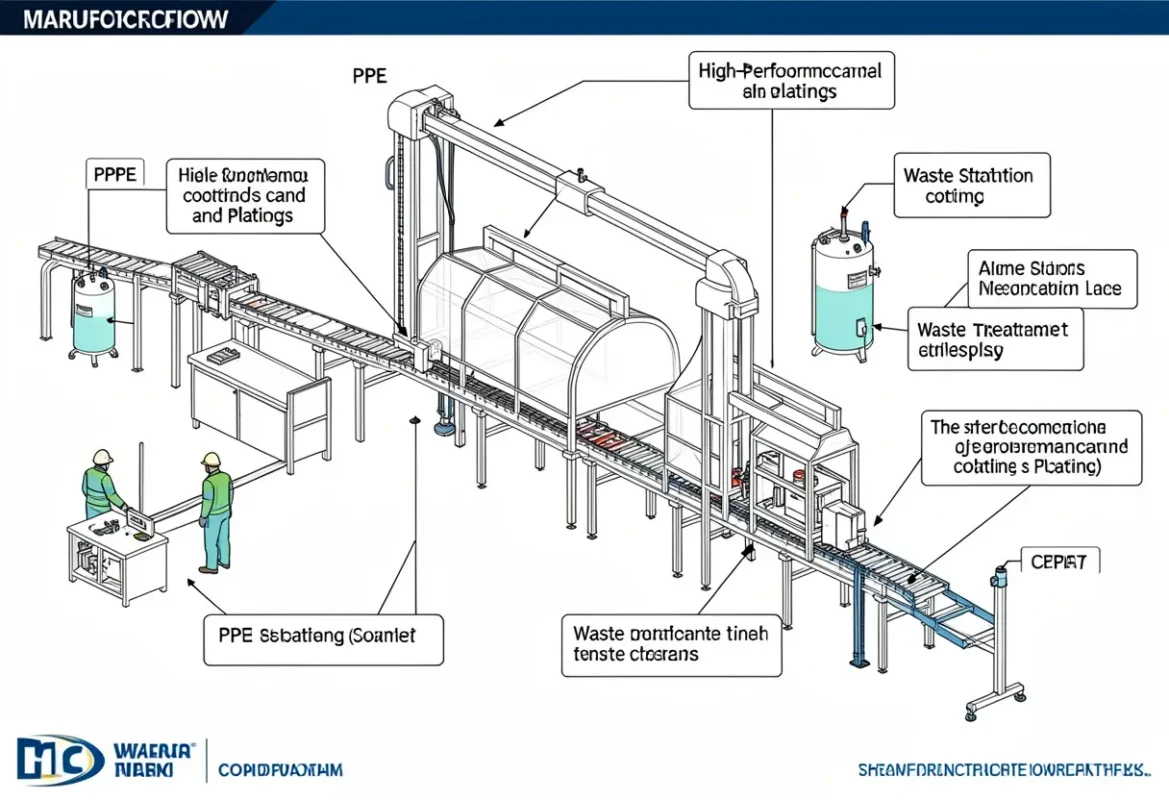

Environmental, Health & Regulatory Considerations

Many high‑performance chemistries and plating processes involve regulated substances and waste streams. We manage RoHS/REACH compliance, hazardous materials handling, and environmental controls for plating and solvent‑based coatings. Choose greener chemistries where possible and document compliance for each production lot.

Recommendations

- Early specification of restricted substances and finish approvals

- Plan waste treatment for electroplating & solvent processes

- Consider life‑cycle costs: recoat intervals, serviceability and environmental disposal

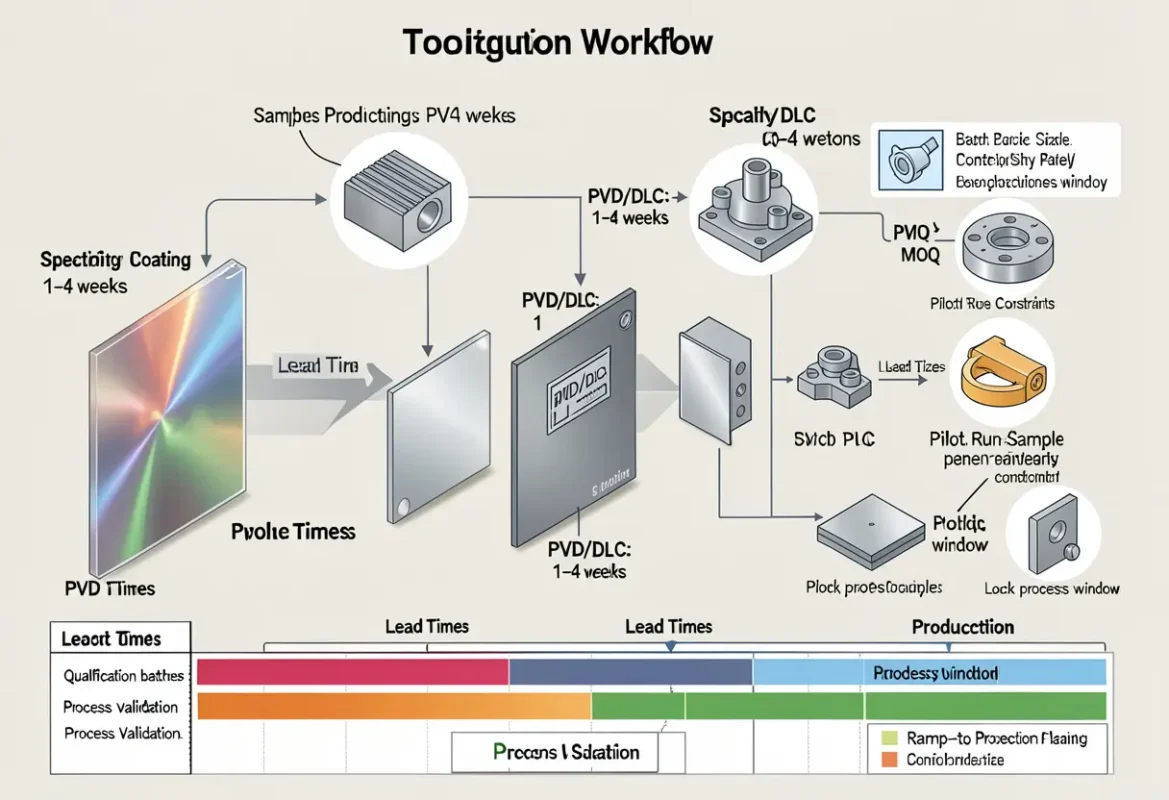

Sourcing, Lead Times & Production Scaling

Representative Projects

High‑Emissivity Coating for Power Module

Applied high‑emissivity black ceramic coating to die‑cast heat spreader, validated with thermal mapping showing 10% lower junction temperature under equivalent power; qualified for 1000 hour thermal cycling.

DLC Coating on Sliding Contact

DLC applied to bearing surfaces reduced friction coefficient by 40% and extended part life >3x in accelerated wear testing; integrated with post‑coat dimensional control for press fit parts.