Surface Finishing Anodize, Plating, Powder Coat, Paint & Functional Coatings

Comprehensive finishing services for metals, plastics and composites. We recommend finishes by function (corrosion resistance, wear, electrical/thermal behavior), appearance, and downstream assembly needs. We also provide testing and validation to prove finish performance under environmental and mechanical stress.

- Anodizing, electroless nickel & electroplating, powder coat, wet paint and e‑coating

- PVD, hard coatings, passivation, polishing and blasting for cosmetic and wear control

- Functional coatings: thermal emissivity, EMI shielding, anti‑fingerprint, anti‑microbial and lubricious coatings

Finishing Categories

Conversion & Electrochemical

Coatings & Paints

Plating & PVD

Electroplating (Ni/Cr/Cu) and PVD for decorative, wear and conductive finishes.

Mechanical Finishes

Functional Coatings

Marking & Identification

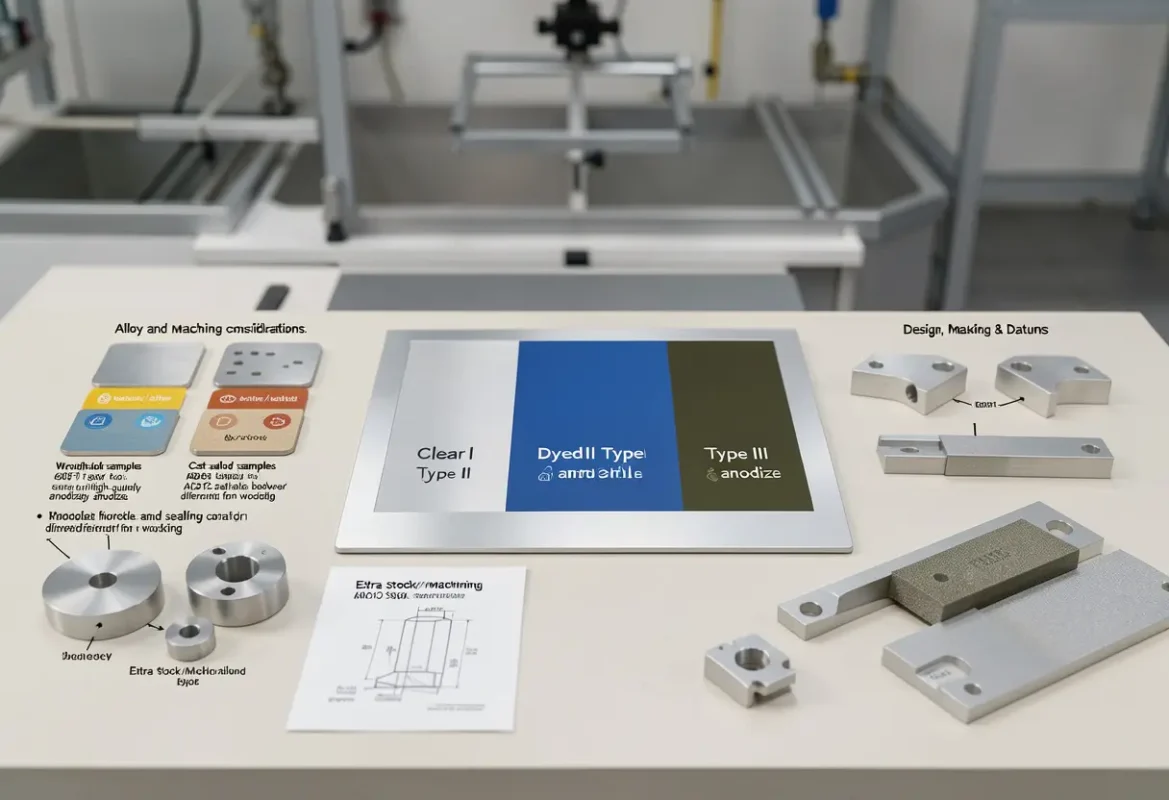

Anodizing & Conversion Coatings (Aluminum)

Anodize creates an oxide layer on aluminum that improves corrosion resistance, wear and dye receptivity. Options include Type II (architectural) and Type III hard anodize for abrasion resistance. Sealing, coloring and clear finishes are available; thickness and sealing method affect corrosion and wear performance.

Design & process notes

- Specify alloy compatibility — some cast alloys (e.g., ADC12) behave differently vs wrought alloys

- Include machining allowance for material removed during finishing or sealing

- Texturing and masking are possible — plan datums that must remain post‑finish

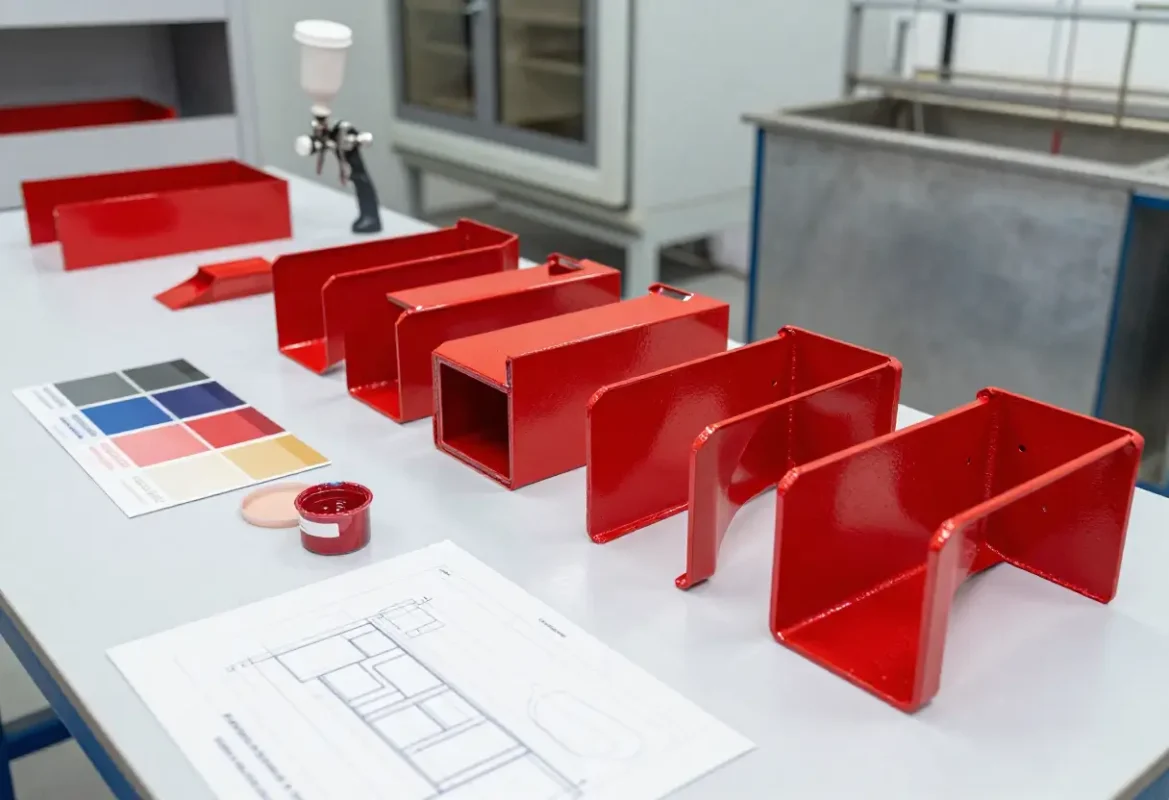

Powder Coating, Wet Paint & E‑Coating

Powder coating provides durable, uniform finishes with good corrosion resistance; wet paint allows fine color matching and specialty coatings. E‑coating (electrophoretic) provides excellent substrate coverage for complex parts and is often used as a pre‑coat prior to powder or topcoat finish for superior corrosion protection.

Notes & tolerances

- Coating thickness affects fit — specify chromatic allowance and final critical datums

- Surface preparation (pretreat, conversion) is critical for adhesion and corrosion performance

- Color matching: use Pantone/RAL and provide samples for approval

Electroplating, Electroless Nickel & PVD

Plating systems (copper, nickel, chrome, gold) provide decorative and functional layers. Electroless nickel offers uniform coverage for complex geometries and wear/corrosion resistance. PVD achieves thin, hard decorative layers without electrolytic chemistry and is suitable for premium finishes.

Considerations

- Substrate compatibility and conductive underlayers may be required for non-metal parts (plastics)

- Plating thickness, adhesion tests and post‑plate machining should be planned into tolerances

- Environmental & RoHS compliance for plating chemistries

Mechanical Finishes Polishing, Blasting & Textures

Mechanical finishes tune appearance and tactile feel: bead blasting for matte finish, brushed finishes for directional texture, polishing for mirror finishes, and tumbling for edge rounding. Texturing affects gloss and perceived quality; factor texture into optical/assembly requirements.

DFM tips

- Specify finish zones and critical datums to avoid unnecessary rework

- High polish surfaces may increase tooling/processing cost — reserve for visible areas

- Blasting media selection affects surface profile and adhesion for subsequent coatings

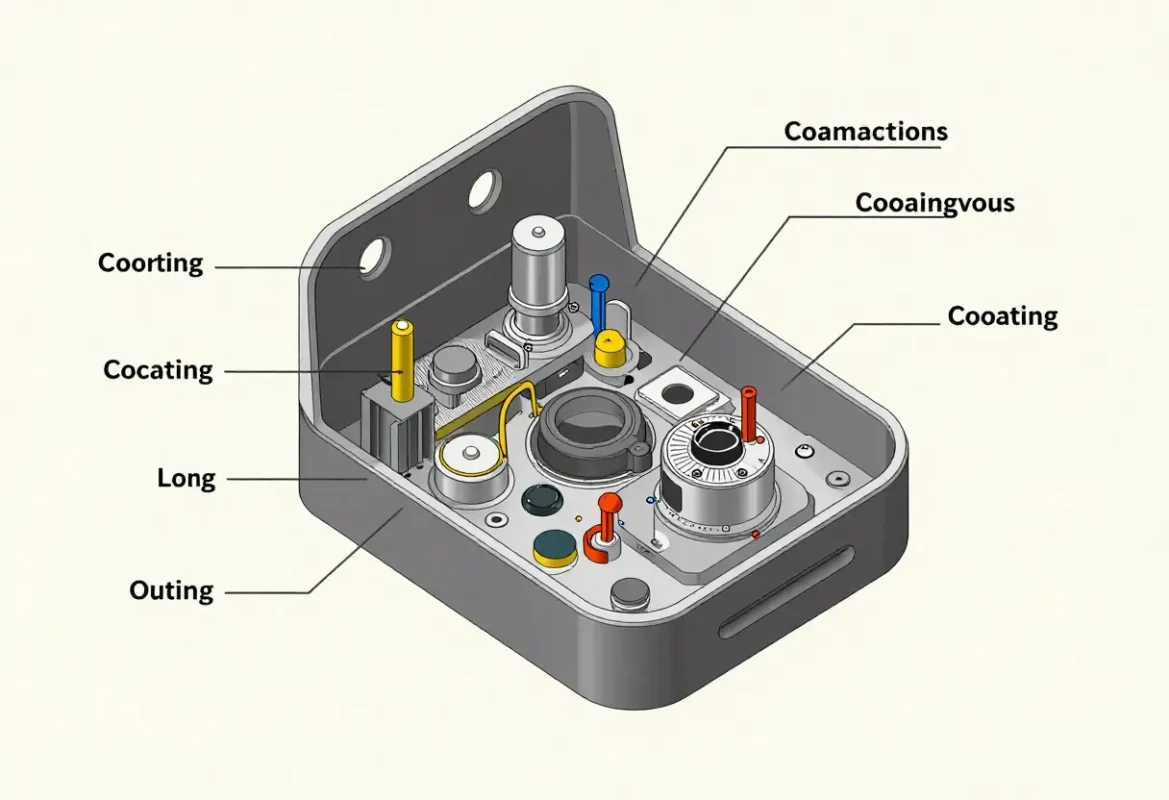

Functional Coatings Thermal, EMI, Anti‑Fingerprint & More

Functional coatings add system performance: thermal emissivity coatings improve heat rejection, EMI conductive coatings or plating provide shielding, anti‑fingerprint and anti‑microbial coatings improve usability and hygiene, and lubricious coatings reduce friction and wear.

Examples

- High emissivity black thermal paints for heat sinks and enclosures

- Conductive paints and plating for EMI/RFI shielding and grounding

- Hydrophobic, anti‑fingerprint or oleophobic topcoats for consumer devices

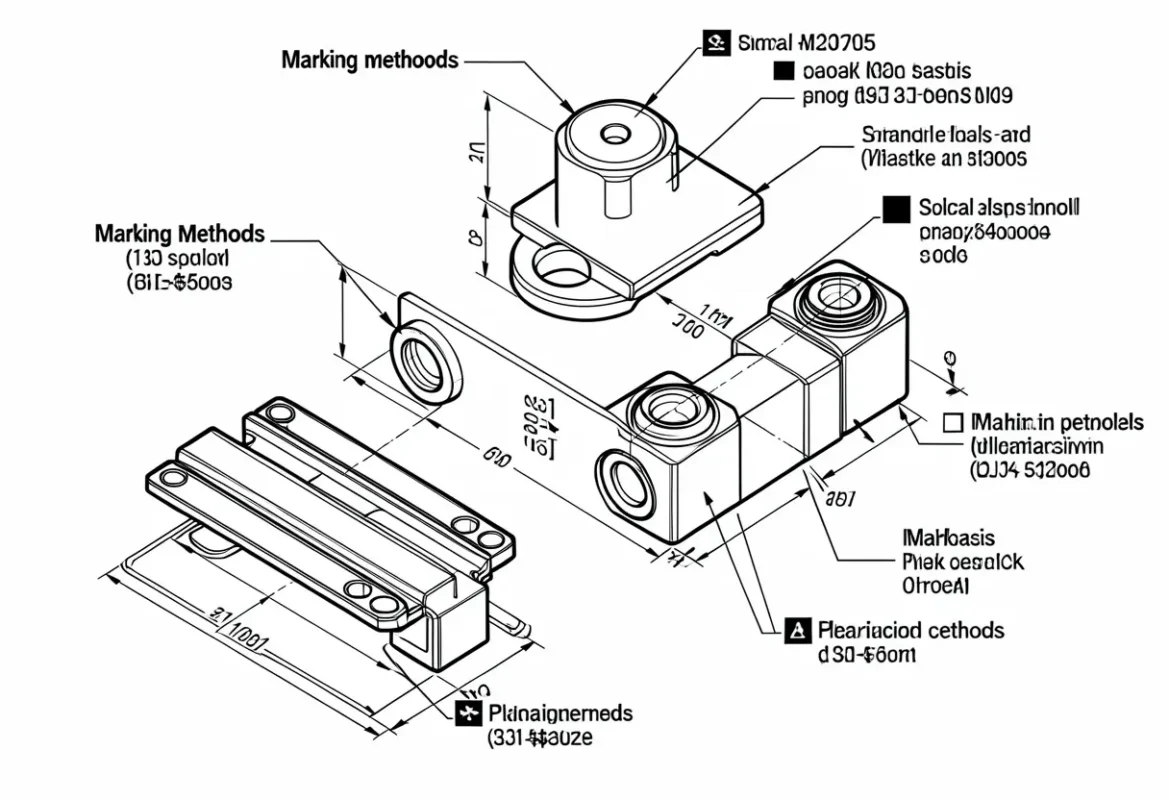

Marking, Identification & Traceability

Permanent marking options include laser engraving, anodized engraving, pad printing, silk screen and dot peen. Select methods based on substrate, required permanence, contrast and cosmetic needs. We also support serialized marking and UID/2D codes for traceability.

Consider

- Contrast and readability over the chosen finish

- Location and tolerance control for readable marks after finishing

- Data matrix or QR for per‑unit traceability and MES integration

Testing, Qualification & Environmental Validation

Finish testing is essential for regulated and outdoor applications. Common tests include salt spray (ASTM B117), cyclic corrosion, humidity, UV exposure, adhesion (cross‑cut/tape), abrasion and Taber wear tests, and color/ gloss measurement. We provide test reports and can build qualification plans for automotive, marine and outdoor specifications.

| Test | Purpose | Typical Standard |

|---|---|---|

| Salt spray | Corrosion resistance | ASTM B117 |

| Adhesion | Coating adhesion | ASTM D3359 (cross‑cut / tape) |

| UV / Weathering | Color and gloss retention | ASTM G154 / G155 |

| Abrasion | Wear resistance | Taber Abraser ASTM D4060 |

Design for Finishing (DFF) Practical Guidance

- Communicate critical datums and tolerances that must remain after finishing

- Specify necessary machining allowances for plating/anodizing/powder coat

- Define masked areas or temporary plugs for threads, holes and sealing faces

- Group parts by finish and color to reduce setup and waste

Typical allowances

| Finish | Typical Thickness | Allowance Guidance |

|---|---|---|

| Anodize | 5–25 µm | Allow 0.05–0.2 mm per surface where tight fit |

| Powder coat | 40–120 µm | Allow 0.1–0.3 mm depending on fit/gasket zones |

| Plating (Ni/Cr) | 5–30 µm | Specify plating thickness and post‑plate machining where needed |

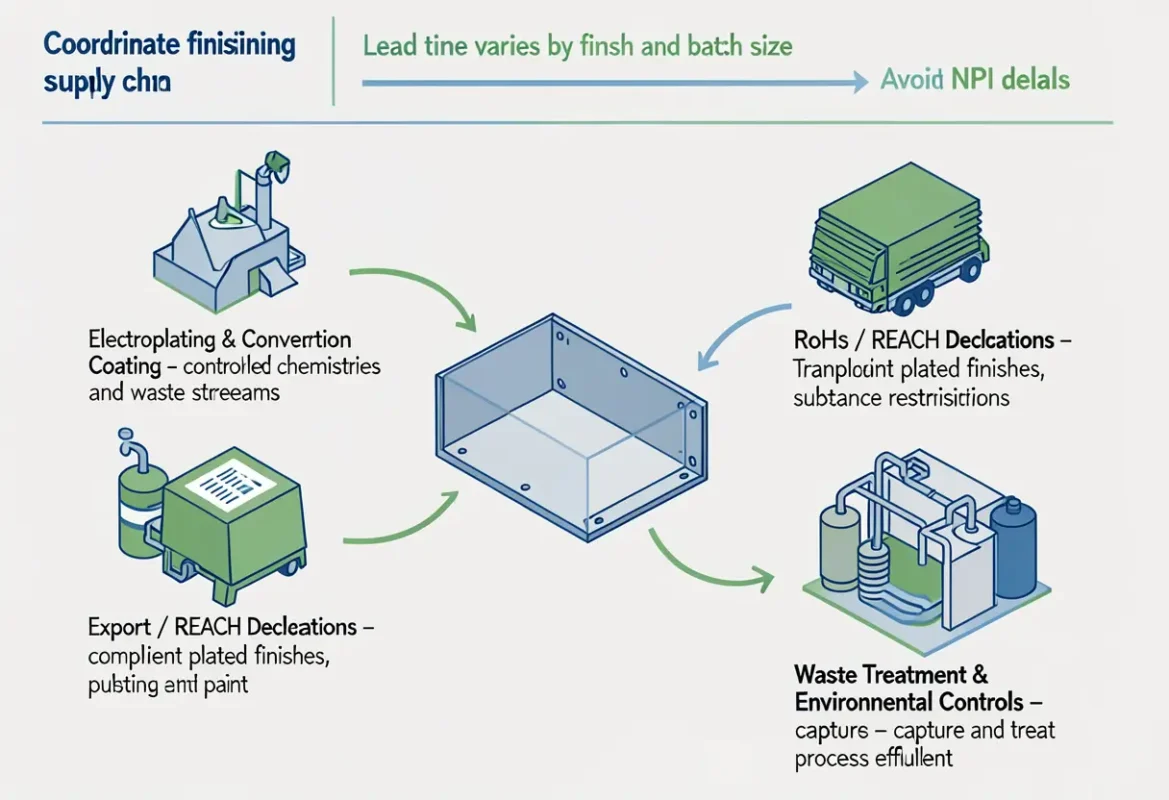

Sourcing, Compliance & Environmental Considerations

Chemistries and waste streams for plating and conversion processes require environmental controls. We manage RoHS/REACH compliance, advise on substance restrictions, and handle pre‑treat and waste management. Lead times vary by finish and batch size — coordinate finishing early to avoid NPI delays.

Regulatory notes

- RoHS/REACH declarations and documentation for plated finishes

- Plating/paint chemistries may have export or hazardous transport constraints

- Waste treatment and environmental controls required for electroplating operations

Representative Projects

Architectural Anodized Lighting Rail

Custom anodize color matched across multiple batches, sealed for coastal installations; delivered color reports and gloss metrics for acceptance.

Die Cast Trim Electroless Nickel + PVD

Electroless nickel underlayer with PVD topcoat achieved durable decorative chrome‑like finish with improved scratch resistance and reduced corrosion in salt spray test.

Specify the Right Finish

Upload your part CAD, substrate, exposure environment and target aesthetic. We’ll recommend finishes, tolerance allowances and a test/qualification plan typically within 24 business hours.