Tooling & Mold Engineering

Metal Stamping, Deep Draw & Progressive Tooling

Comprehensive sheet metal tooling and production: precision progressive and transfer stamping for high volumes, deep draw forming for seamless housings and spinning for rotational parts. We deliver die design, strip layout, tryout, maintenance and PPAP/FAI support for automotive, industrial, lighting and consumer programs.

- Progressive & transfer dies, deep draw tooling, spinning and welded assemblies

- Die engineering: strip layout, station sequencing, coining, piercing and in‑die features

- Tool lifecycle: maintenance, spare inserts, emergency repair lanes and refurbishment

Progressive Stamping — High‑Volume Multi‑Feature Parts

Deep Draw — Seamless Cups & Housings

Spinning & Forming — Reflectors & Domes

What We Offer

From prototype laser/turret cutting to hardened progressive dies, we cover the whole lifecycle: part DFM, die design, die build, tryout, process validation and long‑term maintenance. Our tooling engineers optimize strip layout, blanking, piercing, forming and in‑die secondary operations to deliver lowest total cost at volume.

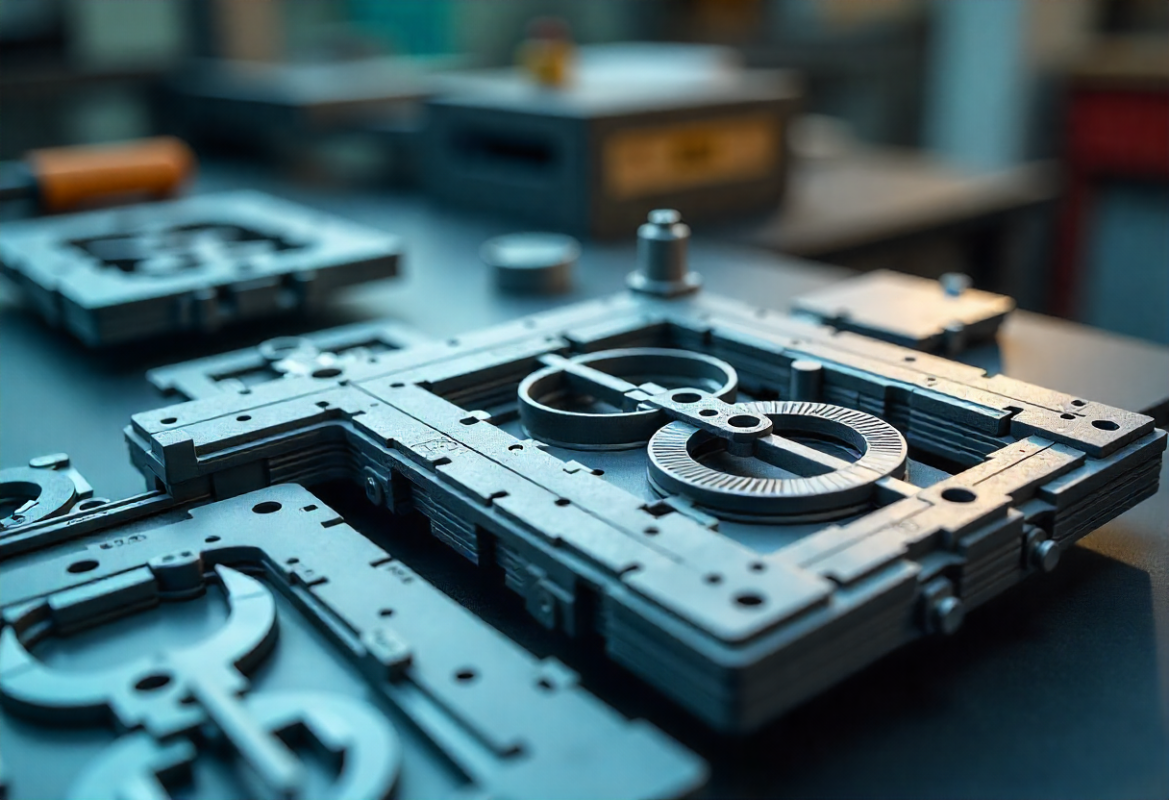

Progressive & Transfer Stamping Tooling

Laser cutting and CNC turret punching deliver fast, tool-free prototypes and low-volume runs. We support quick-turn iterations, sample bending and short-run assemblies to validate fit, form and function before committing to stamping tooling.

Engineering focus

- Strip layout, blank nest and material utilization analysis

- Station sequencing to balance forming loads and reduce scrap

- In‑die secondary operations to reduce downstream cost

- Die life analysis, material selection and heat treat specifications

Deep Draw Forming

Deep draw creates seamless, formed parts (cups, domes, housings) from sheet metal using multi‑stage drawing operations. We engineer draw sequences, blank size, die and punch geometry, lubrication and anneal schedules to avoid wrinkling and tearing while controlling wall thinning and springback.

Design & process notes

- Controlled draw reduction per stage and optimal die radii

- Blank holder and draw ring design to prevent wrinkling

- Intermediate anneal schedules for deep draws in stainless and high-strength steels

Metal Spinning & Flow Forming

Spinning produces axisymmetric parts with excellent surface finish for reflectors, cones and curved housings. CNC spinning enables consistent replication and rapid iteration with low tooling cost for certain geometries, while flow forming is used for thin‑walled cylinders with superior mechanical properties.

Advantages

- Low tooling cost vs deep draw for some parts

- Smooth cosmetic finish and concentricity for optical and acoustic parts

- Fast iteration and short prototype cycles

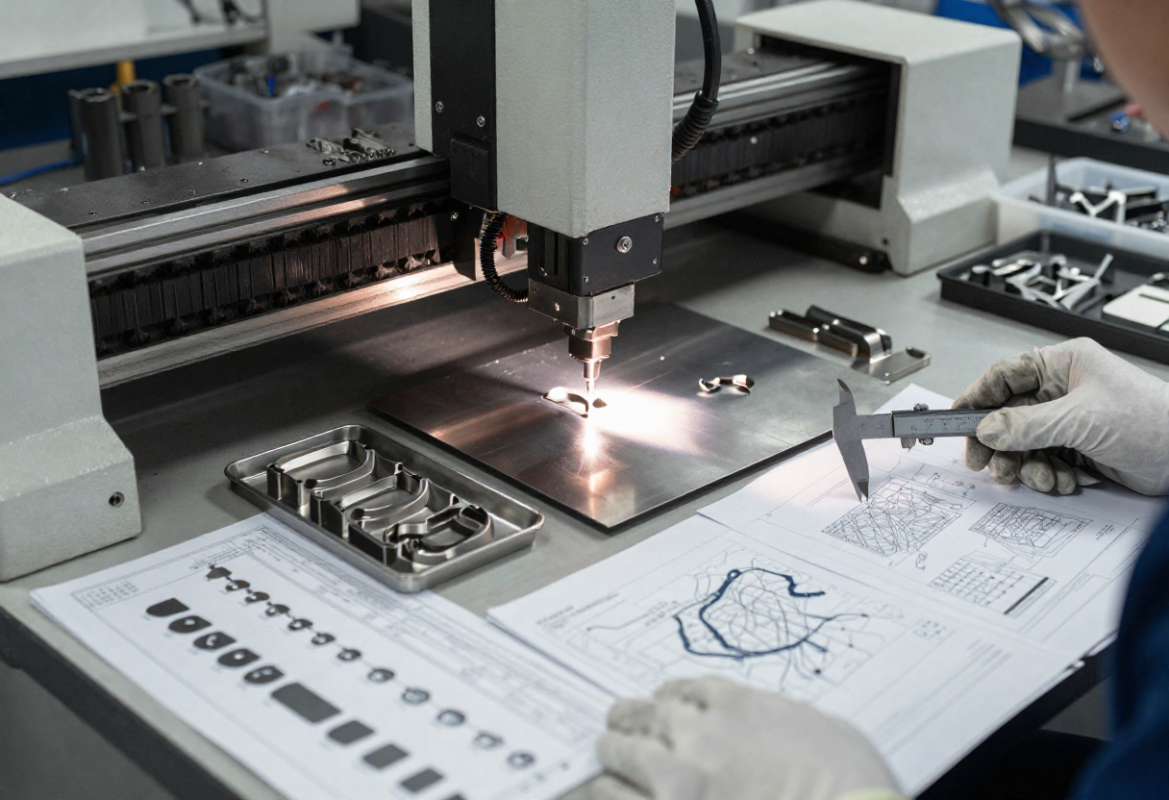

Die Design & Strip Layout

Die design begins with strip layout and blank optimization. We simulate material flow, springback and forming loads, define station functions, and specify die steels and surface treatments. Provisions for quick change inserts and modular stations reduce downtime and cost of future revisions.

Key deliverables

- Strip & nest drawings, 2D/3D die models and station sequence

- Material recommendations and blank size optimization

- Die maintenance plan, spare parts list and operator setup sheets

Tool Materials, Heat Treatment & Coatings

Tool steels selected for stamping and deep draw include S7, H13, D2 and other impact- and wear‑resistant grades. Heat treatment and surface treatments (Nitriding, TiN/DLC coatings) extend die life and reduce galling. We specify maintenance of critical surfaces and recommend spare inserts for high‑wear stations.

Tryout, First Article & Process Validation

Die tryout validates part form, dimensional accuracy, burrs, tool life and cycle stability. Deliverables include FAI/PPAP packages, CMM inspection reports, strip samples, scrap analysis and SPC plans. We establish machine settings, lubrication, coil handling and operator instructions during tryout.

Typical tryout outputs

- Sample strip and part gallery with dimensional data

- Die acceptance checklist and process window

- SPC and inspection frequency recommendations

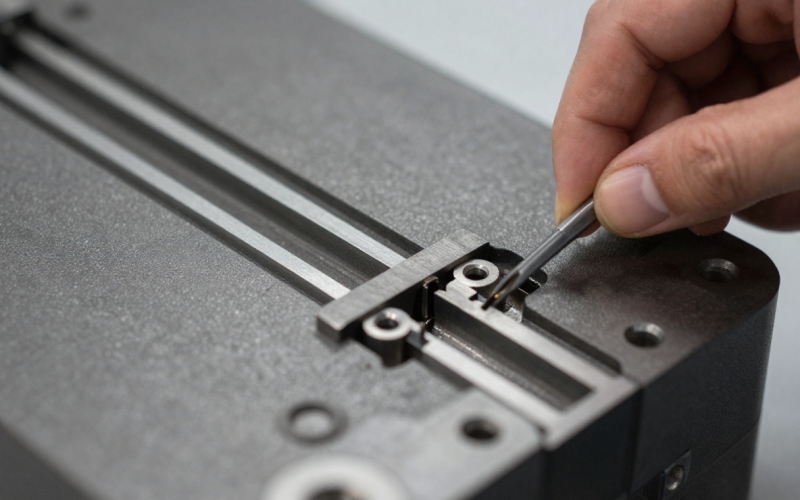

Die Life, Maintenance & Refurbishment

Preventative maintenance, spare station components and timely refurbishment minimize downtime. Our services include die inspection, polishing, EDM rework, re‑hardening, slide rebuilds and spare station provisioning. Emergency repair lanes keep critical lines moving if unplanned issues arise.

Secondary Operations & Assembly Integration

We integrate post‑stamp secondary operations such as tapping, clinching, riveting, welding (MIG/TIG/laser), hemming, bending and forming. In‑die tapping / clinching reduce operations and handling. Final assemblies can include coatings, plating, and controlled finishing prior to kitting and shipment.

Representative Specs & Lead Times

| Tool Type | Typical Lead Time | Notes |

|---|---|---|

| Prototype (laser/turret) validation | Days–2 weeks | No die cost, fast iteration |

| Progressive stamping die | 8–20+ weeks | Station count, hardening and EDM drive schedule |

| Transfer die | 10–22 weeks | Complex multi-stage forming for large blanks |

| Deep draw tool & draw sequence | 8–18 weeks | May require trial anneal steps and iterative tryouts |

Representative Projects

Progressive Bracket Die for EV Inverter

Multi‑station progressive die produced integrated bracket with formed tabs, pierced holes and in‑die clinching, reducing assembly cost and improving dimensional repeatability at 100k pcs/year.

Deep Draw Housing for LED Reflector

Multi‑stage deep draw with intermediate anneal produced seamless reflector with controlled wall thickness and high cosmetic finish; supplied with post‑form machining and plating.

Frequently Asked Questions

How do I decide progressive die vs transfer die?

Choose progressive for small-to-medium sized blanks with many features produced in continuous strip. Choose transfer when blanks are large, heavy, require complex forming sequences or need separate handling between stations. We provide cost/volume analysis to advise.

Can you design in‑die tapping or riveting?

Yes — in‑die tapping, clinching, staking and riveting are integrated where it reduces downstream operations and cost. We evaluate tool sequencing to avoid interference and control tool life.

What tolerances are achievable on stamped parts?

Typical stamping tolerances vary ±0.05–0.25 mm depending on feature, material and secondary machining. Progressive dies with hardened tooling and in‑die control produce the tightest repeatable tolerances at volume.

Start Your Stamping or Deep Draw Project

Upload your flat pattern or 3D model, specify material grade and target volumes. We’ll return process recommendations, tooling options, lead times and an estimated amortization model — typically within 24 business hours.