Assembly & System Integration — Box‑Build, Test & Turnkey Delivery

We provide end‑to‑end assembly and system integration services: PCB kitting and insertion, wiring harness and cable assemblies, enclosure assembly, mechanical integration, firmware/software provisioning, automated test development and final box‑build with serialization and global fulfillment.

Typical Offerings

PCB kitting & placement • Harness & cable assembly • Functional & environmental test • Firmware flashing • Burn‑in racks • Serialization & final packaging.

What We Do

We combine manufacturing, electrical engineering and test development to deliver validated systems ready for field deployment. Our services are optimized for reliability, testability and serviceability to lower lifecycle cost and speed time to market.

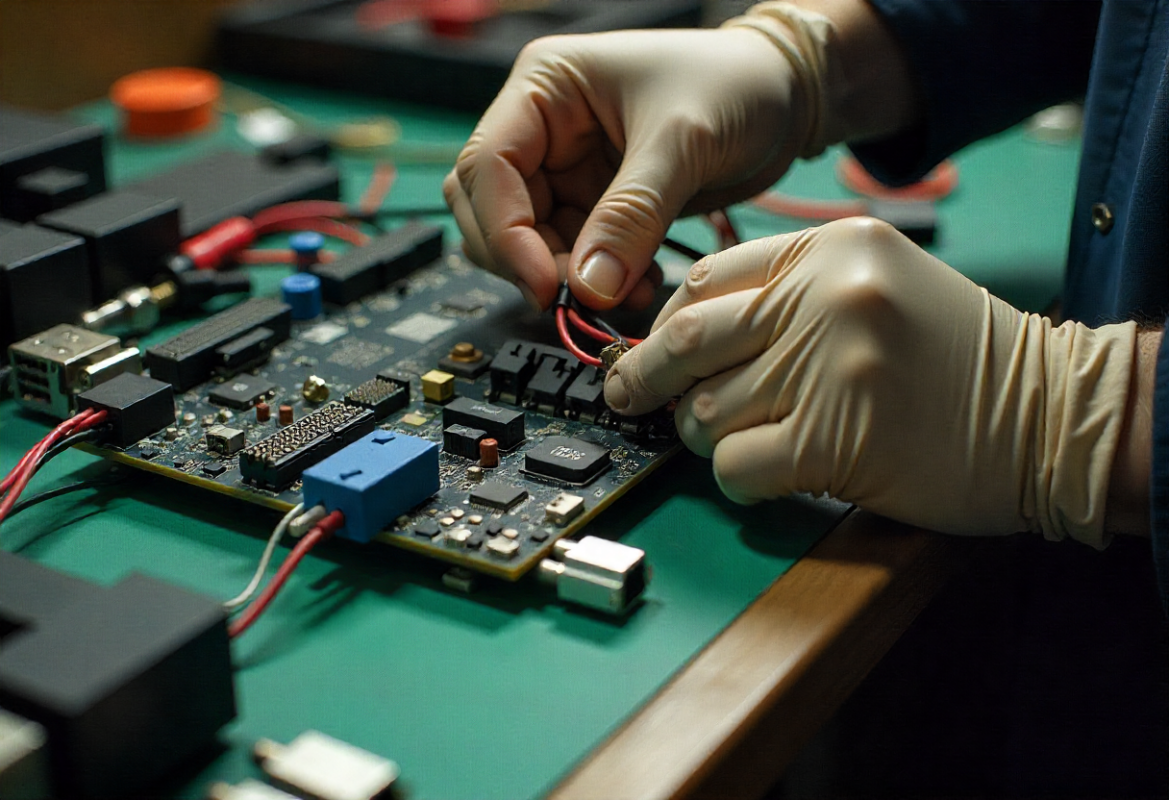

Box‑Build & Mechanical Assembly

From small enclosures to large cabinets: torque control, sealing, gasketing, thermal interface installation and final assembly to drawings.

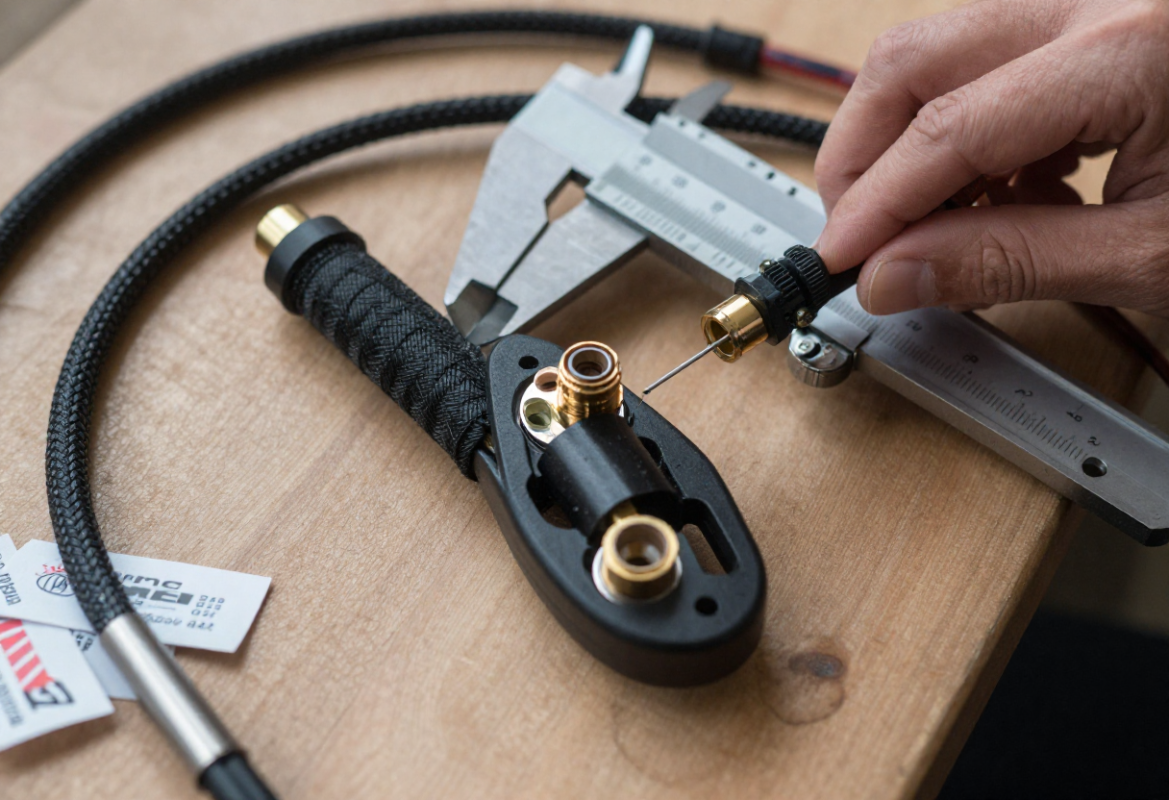

Cable & Harness Assembly

Full harness design support, crimping, overmolding, potting, EMI shielding, and automated test of continuity/insulation.

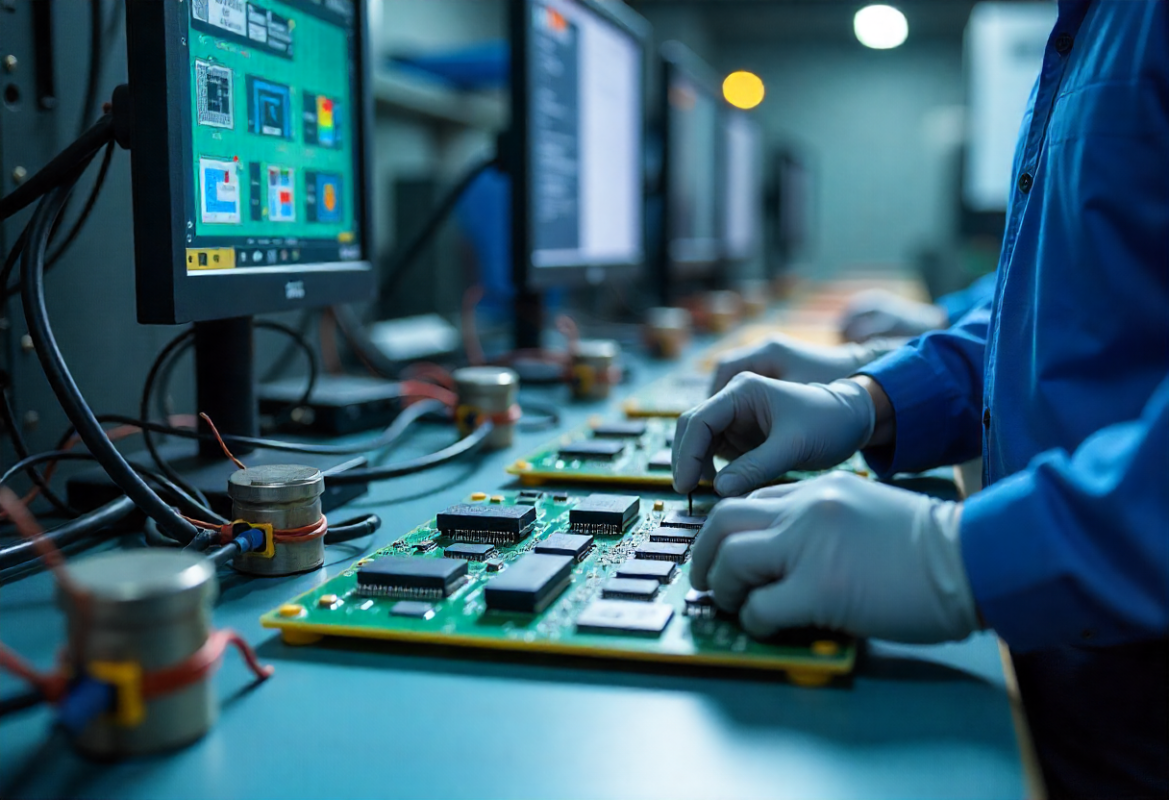

PCB Integration

Complete mill‑turn cellular machining to reduce setups and improve concenKitting, insertion, guided placement, conformal coating, threaded inserts, and mechanical retention for robust assembly.tric tolerances.

Test Development & Validation

We design test fixtures and software to validate electrical and functional performance at scale. Development includes ICT, flying probe, fixturebed/bed‑of‑nails, functional test (FCT), environmental test, automated ATE and burn‑in systems with failure logging and root cause capture.

Test capabilities

- ICT / flying probe for board‑level faults and shorts

- Custom FCT & ATE with DUT interfaces, sensors and fixture control

- Burn‑in racks, thermal cycling, vibration & environmental chambers for reliability validation

- Automated test logging, failure analysis, and actionable repair workflows

Firmware, Software & Configuration

We provision firmware, configure bootloaders, perform secure flashing and support calibration & final acceptance scripts. Options include golden image programming, secure element provisioning, per‑unit keys/credentials and OTA test sequences for communications modules.

Provisioning services

- Firmware flashing and verification

- Calibration & sensor offset programming

- Device provisioning with serialized IDs and cryptographic keys

Wiring Harnesses, Cable Assemblies & Connectivity

We produce harnesses from single‑cable assemblies to complex harnesses with multiple branches, overmolding, shielding and connectors. Processes include automated crimping, optical inspection, Hi‑Pot / continuity testing and assembly into final systems.

Quality controls

- Automated crimp force monitoring and crimp‑pull testing

- Continuity, insulation resistance and Hi‑Pot testing

- Connector retention and mating cycle testing where required

Quality Assurance, Traceability & Documentation

We implement ISO‑grade QA processes with incoming inspection, first article, SPC, and per‑lot/per‑unit reporting. Serialization, UID/2D codes, and MES capture allow full traceability of materials, test records and operator actions.

| Capability | Deliverable | Notes |

|---|---|---|

| FAI / PPAP | First article reports, CMM/ICT/FCT records | Customized to customer and industry (automotive, medical) |

| Serialization | 2D / UID / barcode marking and database linkage | Supports warranty and field service |

| Trace records | Per-unit test logs and operator ID | Stored and exportable via MES |

Supplier Kitting, BOM Management & Fulfillment

We receive, inspect and kit components to BOM for assembly. Services include consigned inventory (VMI), bonded storage, customs handling and global DDP fulfillment. Kitting reduces line downtime and supports JIT production.

Logistics features

- Serialized kitting and barcode scanning at assembly

- VMI and consignment programs to reduce customer inventory burden

- DDP, customs paperwork and Dallas / regional warehousing options

Representative Projects

EV Inverter Box‑Build & Test

Full box‑build: PCBA integration, cold plate installation, harness routing, functional power test & thermal cycling, serialization and final DDP delivery to automotive tier‑1.

Consumer Electronics Assembly & Burn‑In

High‑volume assembly with automated test rigs, burn‑in, cosmetic inspection, customized packaging and direct fulfillment to e‑commerce channels.

Frequently Asked Questions

What input files help you quote an assembly?

Provide BOM with part numbers, CAD assembly (STEP), PCB Gerbers or ODB++, test requirements, expected volumes, and any regulatory constraints. Photographs or reference units speed assessment.

Can you develop custom test fixtures and software?

Yes — we develop mechanical fixtures, electrical fixtures and test software (LabVIEW, Python, C# or custom ATE) and provide maintenance packages for test hardware and SW.

How do you handle ESD sensitive assemblies?

We use ESD workstations, ionizers, wrist/foot straps, ESD packaging, static-safe kitting and trained operators in ESD-controlled areas or cleanrooms as required by product sensitivity.

Plan Your Assembly & Integration

Upload your BOM, assembly drawings and test requirements. We’ll return a recommended assembly flow, test strategy, fixturing concept and quote — typically within 24 business hours.