Full Electromechanical Assemblies — Box‑Build, Harnesses & Turnkey Systems

We build complete electromechanical systems: mechanical structure, PCB population, wiring harnesses, cable assemblies, connectors, thermal subassemblies and firmware where required. Our box‑build service covers prototype to high‑volume production, functional testing and global fulfillment with traceability and compliance documentation.

- Box‑build assembly: mechanical + electronic integration, sealing and final enclosure

- Wiring harness & cable assembly production with crimp, overmold and shielding

- Custom test fixtures: ICT, FCT, burn‑in, environmental and functional testing

Aluminum Castings

Vacuum & Low‑Pressure

CNC Finishing

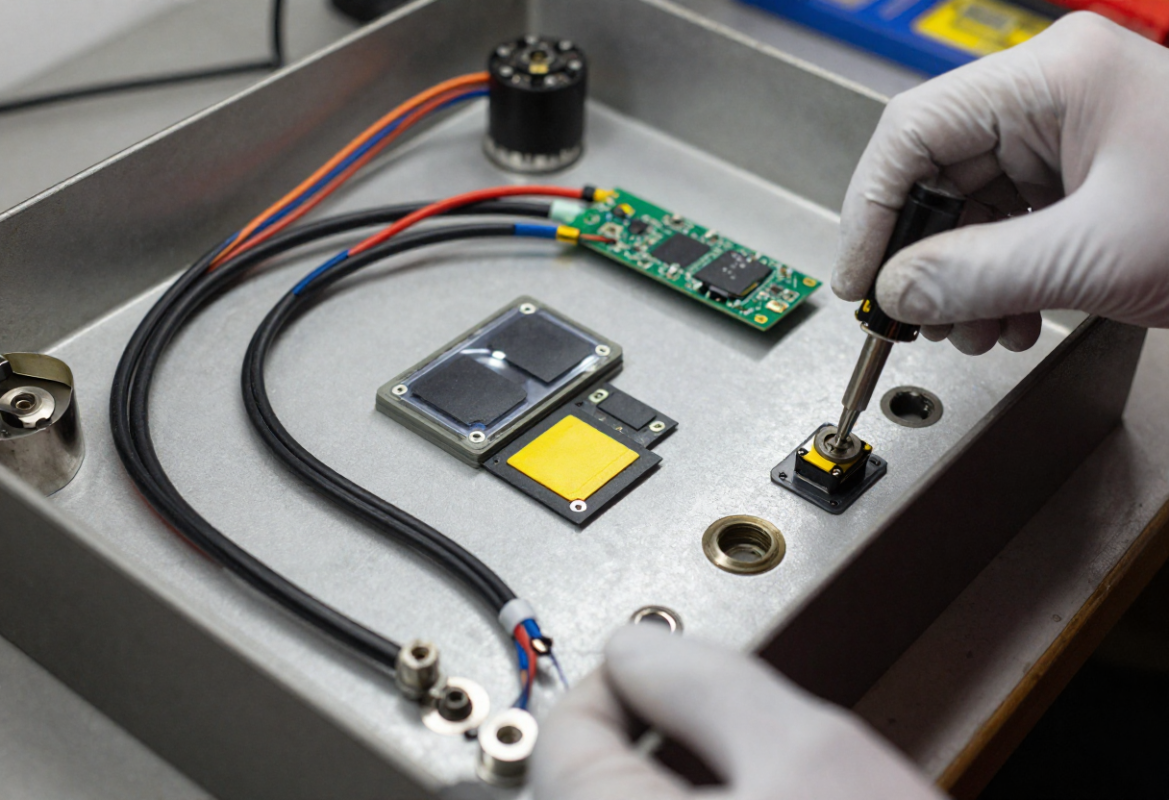

What Is a Full Electromechanical Assembly?

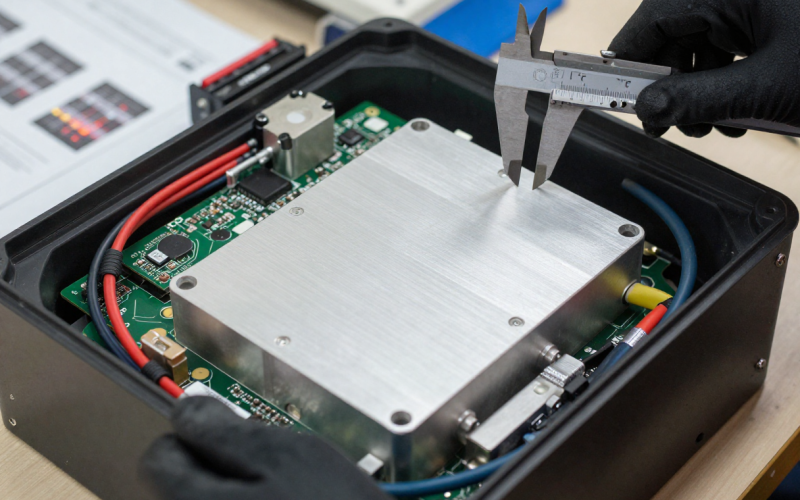

A full electromechanical assembly (box‑build) combines mechanical parts, one or more PCBs, wiring harnesses, connectors, sensors, motors and firmware into a single ready‑to‑install product. We handle all build steps including PCB population, cable assembly, mechanical fitment, sealing, functional test and packaging — delivering a validated system with traceable documentation.

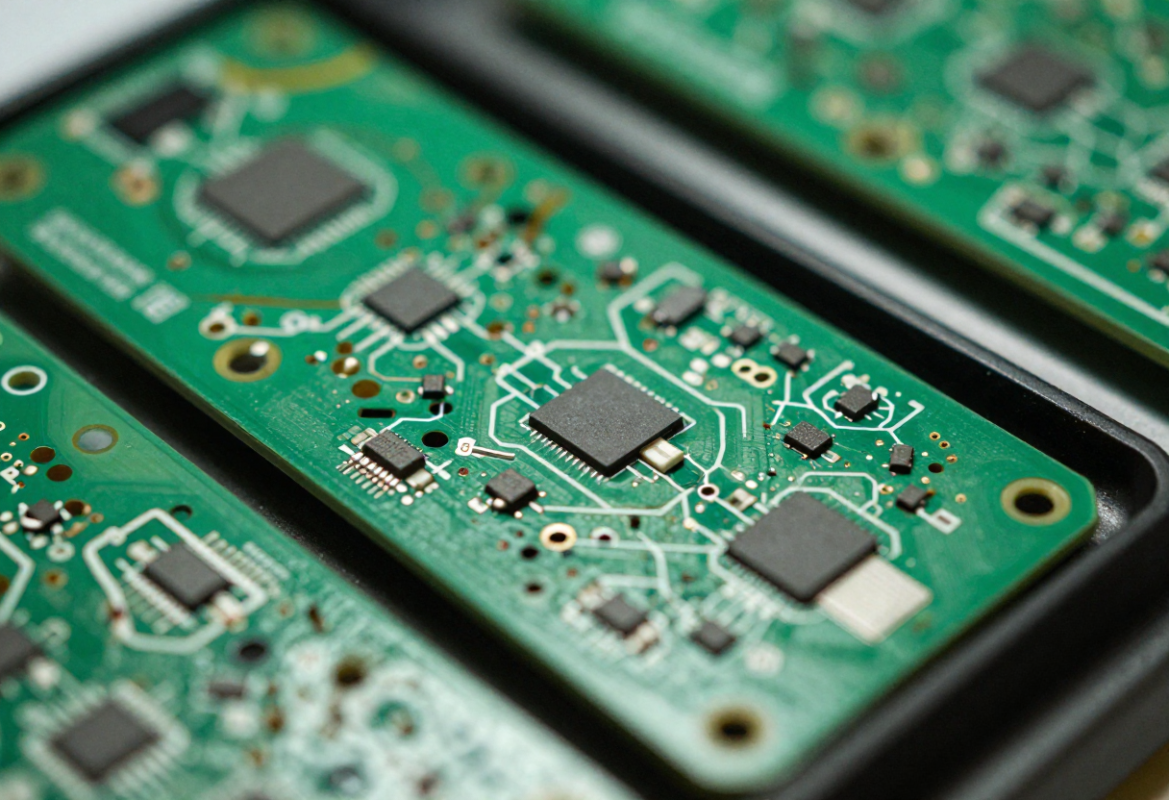

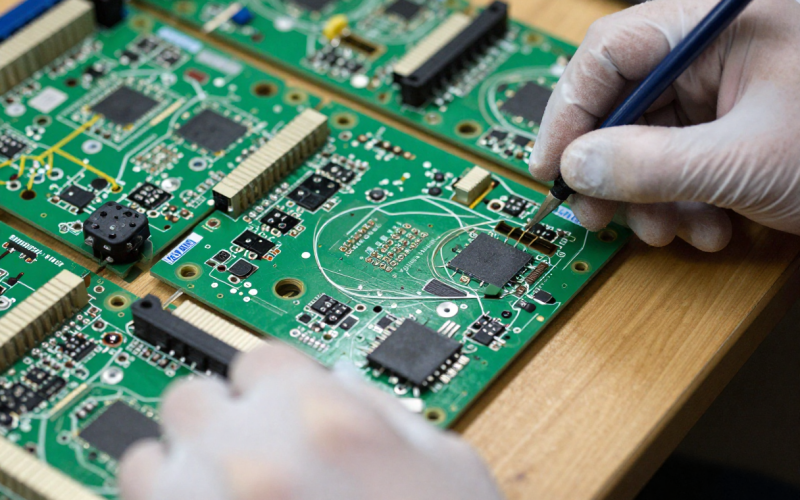

PCB Population & Electronics Integration

SMT & through‑hole assembly, conformal coating, selective soldering, potting and firmware programming. We support small boards through multi‑panel, high‑mix production.

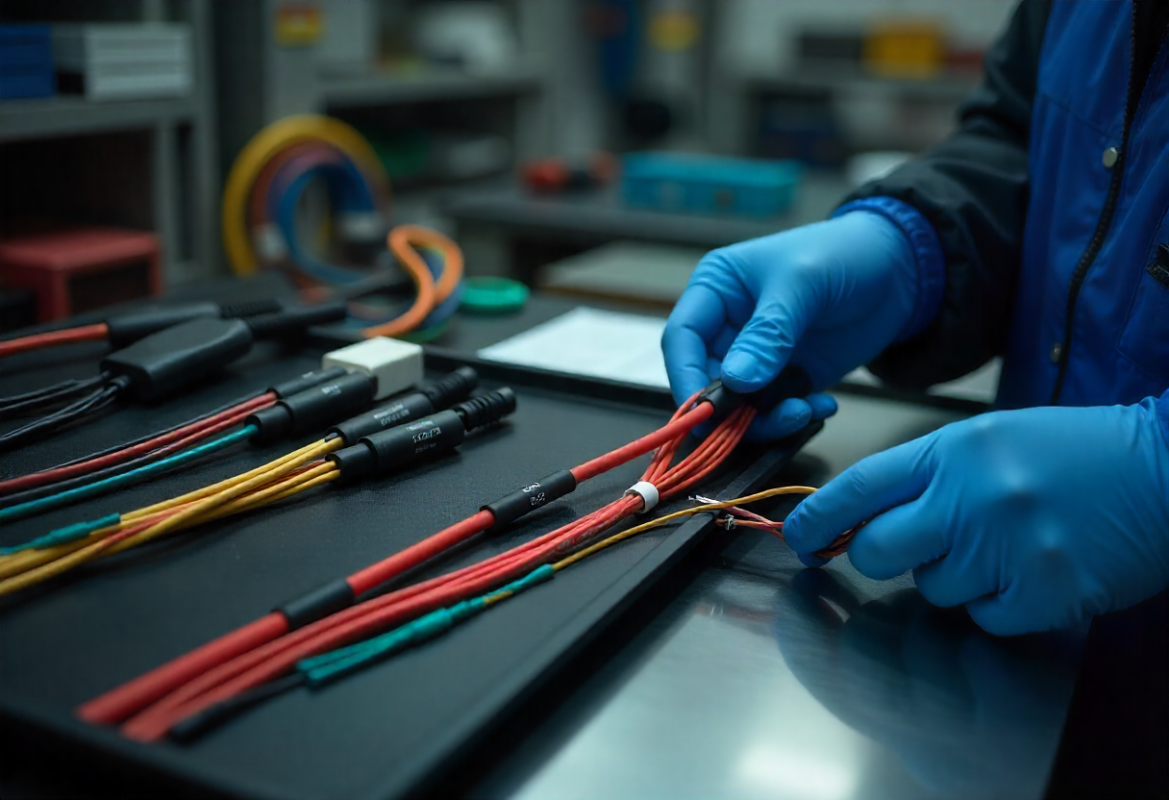

Wiring Harnesses & Cable Assemblies

Crimp terminals, IDC, solder terminations, overmolding, shielded assemblies, braided sleeves and harness routing to meet electrical, EMC and environmental requirements.

Mechanical Assembly & Enclosures

Box build integration including fasteners, adhesives, gasketing, seals, thermal interfaces, and final mechanical alignment within tolerance budgets.

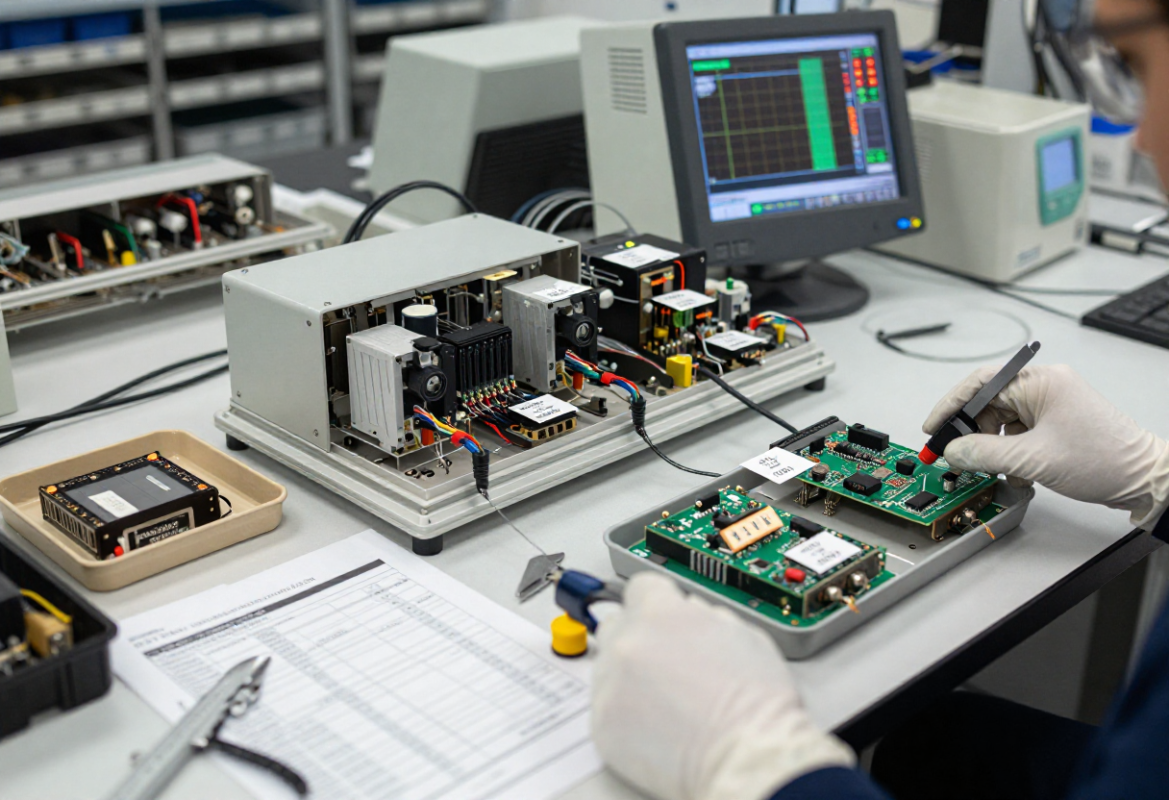

Functional Test & Burn‑In

Custom test fixtures, ICT/FCT protocols, automated burn‑in racks, calibration and certificate generation to validate electrical and mechanical performance prior to shipment.

Wiring Harness & Cable Assembly Services

Our harness capabilities include automated crimping, 100% pull‑test, inline inspection, overmolding for strain relief, integrated shielding and custom connector termination. We provide harness design for manufacturability and can supply BOM‑level kitting for on‑line assembly or ship harnesses separately.

Quality & inspections

Electrical continuity, hipot/insulation test, tape & tie routing, length verification and visual inspection per IPC/WHMA standards.

Box‑Build Assembly & Mechanical Integration

We assemble mechanical enclosures, fit and route harnesses, install PCBs, subassemblies, thermal components and perform sealing and final fastening. We provide controlled torque, adhesive dispensing, press‑fit insertion, adhesive curing and final cosmetic inspection.

Service models

Kitted build: customer supplies components; turnkey: we source and manage BOM; hybrid: we manage long‑lead components while customer supplies critical parts.

Testing & Verification

We create custom test fixtures for ICT, FCT, power up checks, sensor calibration and communications validation. Environmental testing includes thermal cycling, humidity soak, vibration, shock and ingress testing for sealed assemblies.

Burn‑in & reliability

Burn‑in racks with controlled power profiles and temperature to detect infant mortality. Failure analysis and corrective action for any detected defects are part of our NPI loop.

Test Data & Traceability

Each unit can be serialized with test certificates, measurement logs, firmware version, assembly operator records and lot traceability. Reports are provided as part of FAI/PPAP or per customer format.

Reporting options

Per‑unit test records (CSV/PDF), SPC dashboards, long‑term burn‑in logs and consolidated lot certificates for regulatory or warranty requirements.

Component Sourcing & Supply Chain

We manage long‑lead procurement, BOM consolidation, component obsolescence mitigation and ESD/temperature‑controlled logistics. Options include vendor qualification, dual‑sourcing, consigned stock, VMI and US warehousing to support just‑in‑time deliveries.

Vendor compliance

RoHS/REACH compliance, material certificates (MTR), traceable lots and secure sourcing for regulated industries such as medical and automotive.

Packaging, Kitting & Global Fulfillment

Custom packaging for transit (shock, vibration, humidity control), kitting for assembly lines, serialized packing lists and global DDP/EXW shipping. We support aftermarket spares, service kits and US warehouse fulfillment for fast delivery.

After‑sales & repair

Return merchandise authorization (RMA) workflows, repair & refurbishment lines, spares management and technical support handoffs to OEMs or service partners.

Applications

Medical Devices & Diagnostics

Functionally tested assemblies with cleanroom options, traceable components and firmware control for clinical use.

Telecom & Networking

Rack modules, line cards, power shelves and sealed outdoor units with harness harnesses and thermal management.

Industrial Controls & Automation

HMI enclosures, motor controllers, valve controls and integrated sensor assemblies with rugged environmental protection.

Representative Projects

Thermal Power Module Box‑Build

Integrated cold plate, populated PCBs, harness, and sealed enclosure with FCT and 48‑hour burn‑in. Delivered serialized units with FAI and thermal maps for automotive supplier release.

Telecom Line Card Assembly & Test

High‑mix SMT population, custom harness routing, ICT and FCT fixtures—scaled to volume with automated optical inspection and per‑unit test reports.

Frequently Asked Questions

What documentation is provided with assembled units?

Typical deliverables: FAI/PPAP, per‑unit test certificates, serial numbers, firmware version logs, material certificates and assembly traveler records.

Can you support small NPI pilot runs before volume?

Yes — we do pilot builds with controlled yields, detailed process setup, capability studies and pre‑production validation to ensure smooth ramp to volume.

How are obsolescence and BOM changes handled?

We maintain component lifecycle monitoring, propose drop‑in substitutes where possible, run engineering change orders (ECO) and maintain revision traceability in BOM management systems.

Ready to Build Your Electromechanical Assembly?

Upload your assembly drawing, BOM and target volumes. We’ll return manufacturability feedback, recommended test plans and a NPI path — typically within 24 business hours.