Speaker & Audio Structural Components — Frames, Enclosures & Acoustic Subassemblies

We design and manufacture structural and acoustic components for loudspeakers, headphones, microphones and audio systems — combining mechanical precision with acoustic performance. Deliverables include stamped/pressed frames, die‑cast baskets, injection‑molded enclosures, magnet housings, grills, acoustic chambers and full speaker subassemblies with acoustic validation.

- Enclosures, frames, baskets, magnet housings and voice‑coil supports

- Materials and finishes selected for stiffness, mass, thermal and acoustic behavior

- Prototype → NPI → volume with acoustic test validation (impedance, FR, THD)

Magnet Housings

Frames & Baskets

Enclosures & Chambers

What We Make

Stamped & Spun Speaker Frames

High‑precision stamped steel frames and spun aluminum baskets for consistent geometry and mounting. We produce parts that control modal behavior and minimize resonance.

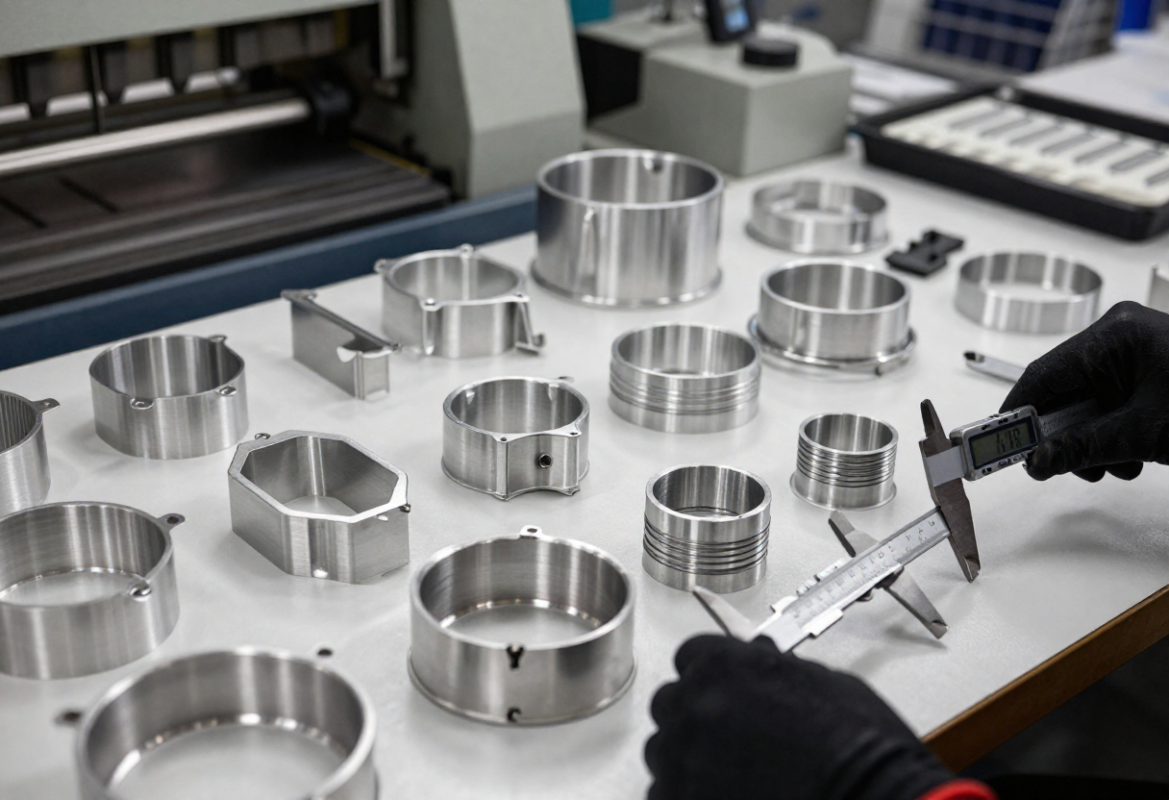

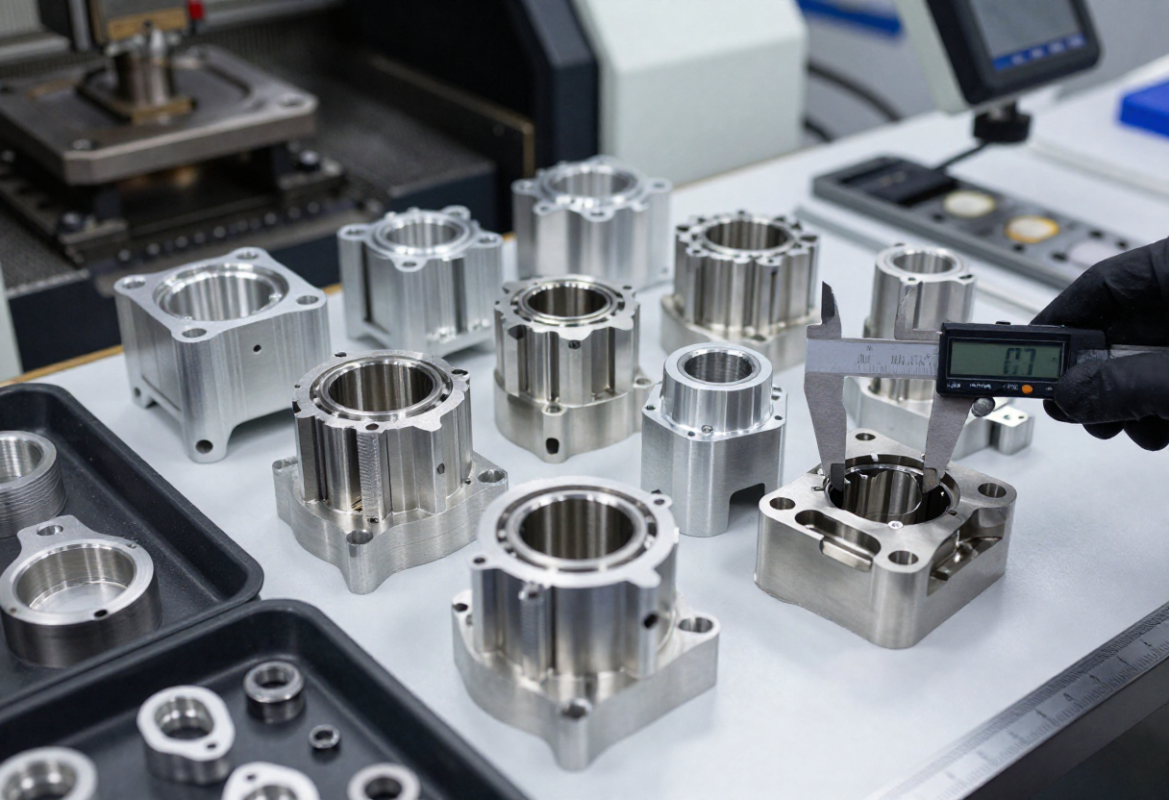

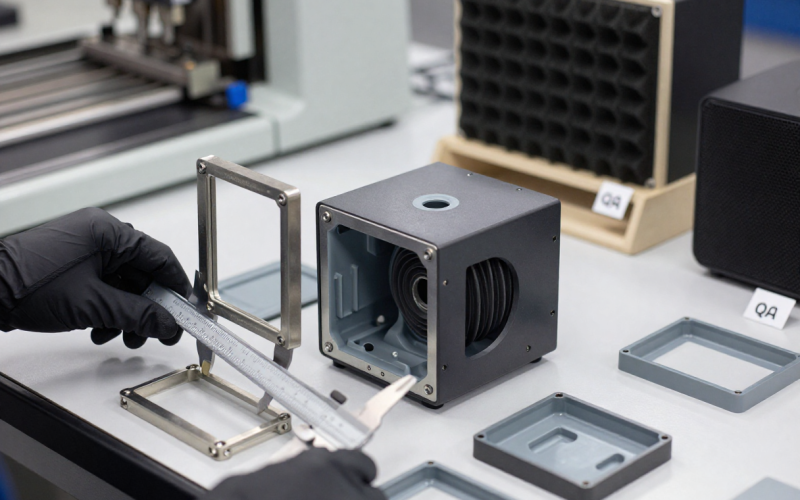

Die Cast & Machined Magnet Housings

Die cast aluminum or CNC‑machined steel housings for magnets and motor assemblies with tight concentricity and thermal path control.

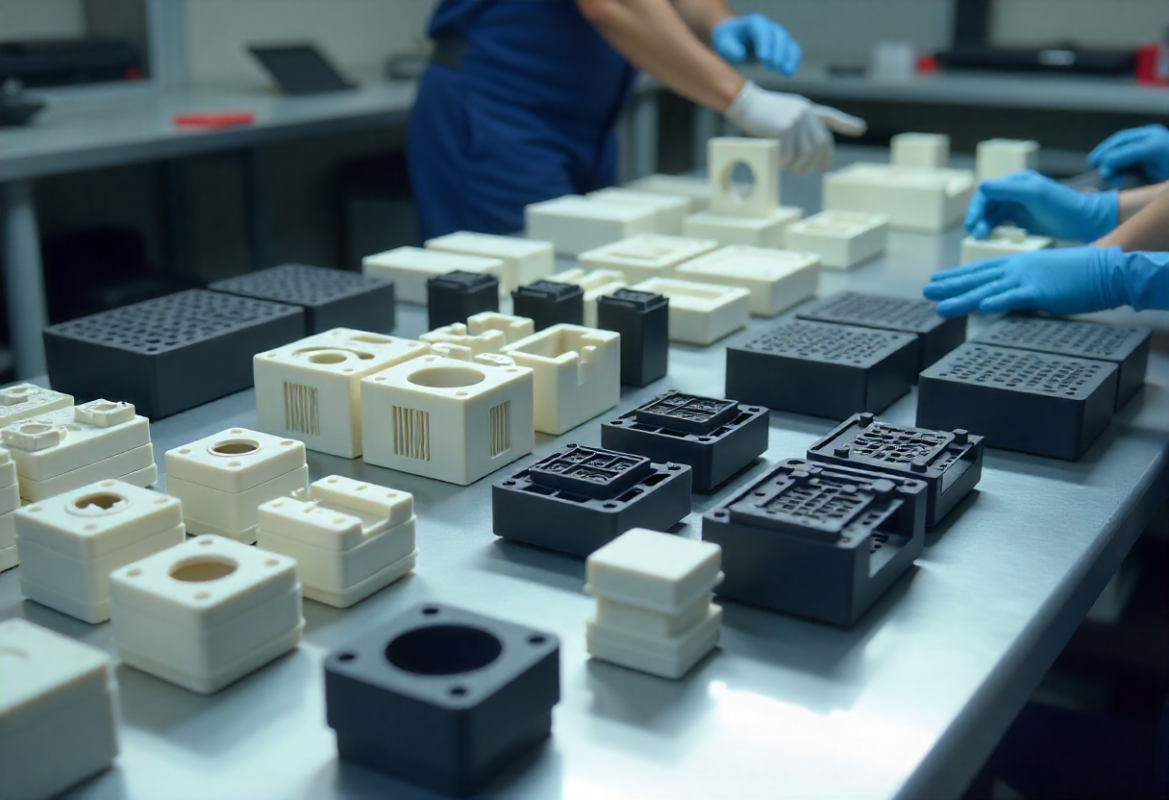

Injection Molded Enclosures & Grills

Plastic enclosures, passive radiator chambers and acoustic grills with integrated ribs and mounting features for ease of assembly and acoustic tuning.

Design & Acoustic Engineering

We partner with acoustical engineers to align mechanical design with target frequency response, sensitivity and distortion. Services include modal analysis, vibro‑acoustic FEA, enclosure tuning (ported vs sealed), and mechanical DFM to minimize assembly variance that affects acoustics.

Deliverables

CAD models, FEA modal reports, enclosure tuning notes, BOM for subassemblies, and recommended manufacturing tolerances for consistent acoustic outcomes.

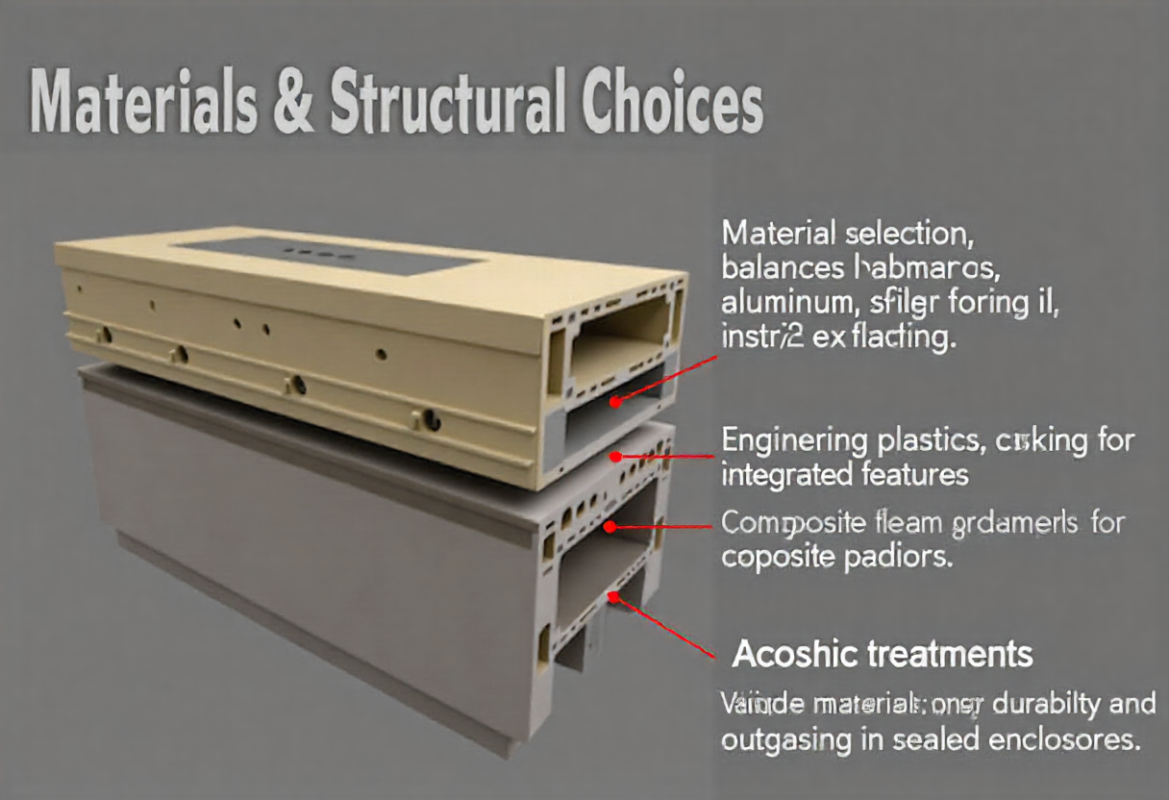

Materials & Structural Choices

Material selection balances stiffness, mass and damping. Options: stamped steel (stiff, economical), aluminum (lightweight, thermally conductive), magnesium (stiff & light), engineering plastics for integrated features, and composite laminates for premium acoustic panels.

Acoustic treatments

Integrate acoustic foams, resonant chambers, damping pads, and tuned passive radiators. We validate materials for durability and outgassing in sealed enclosures.

Manufacturing Processes

Stamping & Spinning

Progressive stamping for frames and brackets; metal spinning for seamless reflectors and cones with excellent surface finish and concentricity.

Die Casting & CNC Finishing

Die casting for complex magnet housings and bosses; CNC finishing to control mating surfaces, bosses and concentricity for voice‑coil alignment.

Injection Molding & Overmolding

Injection molding for enclosures, grills and integrated features; overmolding for soft touch surfaces and integrated seals. Molded ribs and baffles simplify assembly and acoustic tuning.

Adhesive Bonding & Final Assembly

Controlled adhesives for diaphragm bonding, gasketing, potting and vibration isolation. We provide automated assembly, adhesive dispensing and curing lines to maintain acoustic consistency.

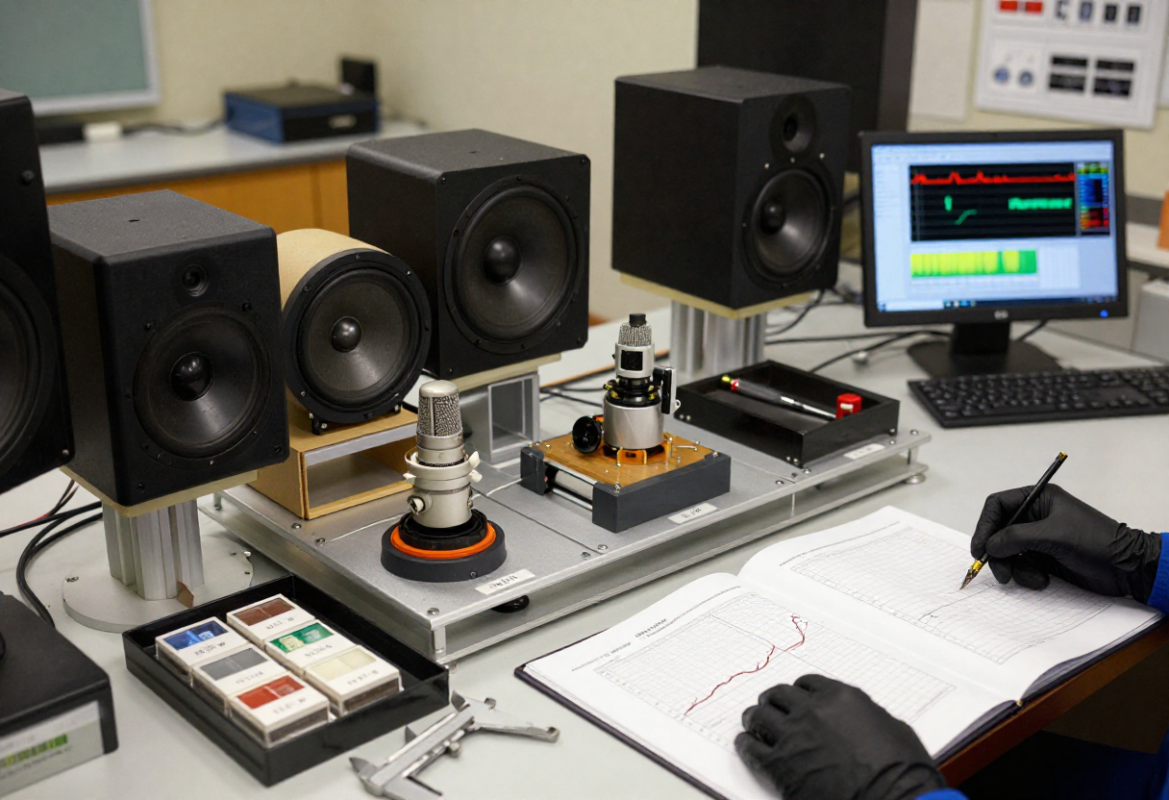

Acoustic & Mechanical Validation

We run acoustic test benches for impedance measurement, frequency response (FR), total harmonic distortion (THD), sensitivity, and waterfall plots. Mechanical testing includes drop, vibration, thermal cycling and assembly torque repeatability checks.

Typical lab deliverables

Impedance sweeps, FR curves, THD vs SPL, burst/step response, and assembly variance reports tied to acoustic performance.

Reliability & Environmental Testing

Safety & regulatory

Typical Specifications & Design Guidance

Below are representative design guidelines to help estimate manufacturability, part cost and acoustic impact. Final specs should be refined with prototypes and acoustic testing.

Frame Concentricity

Concentricity within 0.05–0.2 mm for voice‑coil alignment (post‑machining achievable tighter).

Basket Flatness

Flatness zones ≤ 0.1–0.5 mm depending on mounting interface and tolerance.

Material Mass Targets

Enclosure mass tuned to resonance targets — heavier shells lower panel resonances; lightweight baskets for sensitivity.

Surface Finish

Powder coat, anodize, soft‑touch paint, PVD or chrome plating for grills and trim.

| Parameter | Typical Range | Notes |

|---|---|---|

| Frame materials | Steel, Al, Mg, die cast alloys, plastics | Select for stiffness, cost and thermal behavior |

| Diaphragm mounting | Press fit / adhesive / rivet | Adhesive bonding for consistent centering & damping |

| Grill perforation | Pattern & open area optimized for acoustics | Balance protection vs transmission loss |

| Lead time (prototype) | 1–6 weeks | Depends on process (stamped / molded / cast) |

Applications

Consumer & Smart Speakers

Integrated enclosures and tuned chambers for small form factor speakers and smart devices.

Automotive Sound Systems

Vehicle‑grade frames, magnet housings and sealed enclosures for door, dash and subwoofer installations.

Pro Audio & Studio Monitors

High‑rigidity baskets, machined magnet assemblies and tuned ported enclosures for accurate reproduction.

Representative Projects

Die‑Cast Magnet Assembly for Car Subwoofer

Die cast mag housing with post‑machined flange and integrated thermal venting reduced voice coil temperature rise and improved long‑term power handling.

Stamped Frame & Injection Enclosure for Smart Speaker

Stamped frame combined with injection molded enclosure and tuned internal chamber produced a cost‑efficient assembly that met FR and sensitivity targets at scale.

Frequently Asked Questions

How do structural tolerances affect acoustics?

Mechanical tolerances (concentricity, flatness and mounting repeatability) directly influence voice‑coil centering and suspension behavior — small deviations can raise distortion or alter frequency response. We advise tolerance budgets tied to acoustic goals.

Can you help with acoustic tuning and enclosure design?

Yes — we collaborate on enclosure volume, port tuning, passive radiator sizing, and recommend damping materials. We provide prototype testing to validate tuning choices.

Do you handle full speaker subassembly and testing?

Yes — we provide subassembly (diaphragm bonding, voice coil insertion), electrical testing (impedance, polarity), acoustic bench testing, final assembly and packaging for distribution.

Start Your Speaker or Audio Component Project

Upload your CAD, power & SPL targets, enclosure preferences and target volumes. We will return manufacturability feedback, acoustic integration recommendations and a prototype plan — typically within 24 business hours.