Casting Components — Sand, Gravity, Investment & Forging

We deliver cast and forged components engineered for structural strength, complex geometry and production scale. Our services include pattern and die engineering, sand & gravity casting, precision investment casting, closed‑die forging, secondary CNC finishing, heat treatment and comprehensive NDT & quality documentation.

- Process matching: sand casting, gravity cast, investment (lost‑wax), and closed‑die forging

- Tooling & pattern design, gating/riser optimization and pilot runs

- Secondary finishing: CNC machining, heat treat, shot peen, plating and NDT

Investment Casting

Closed‑Die Forging

Superior mechanical properties and fatigue performance for critical parts.

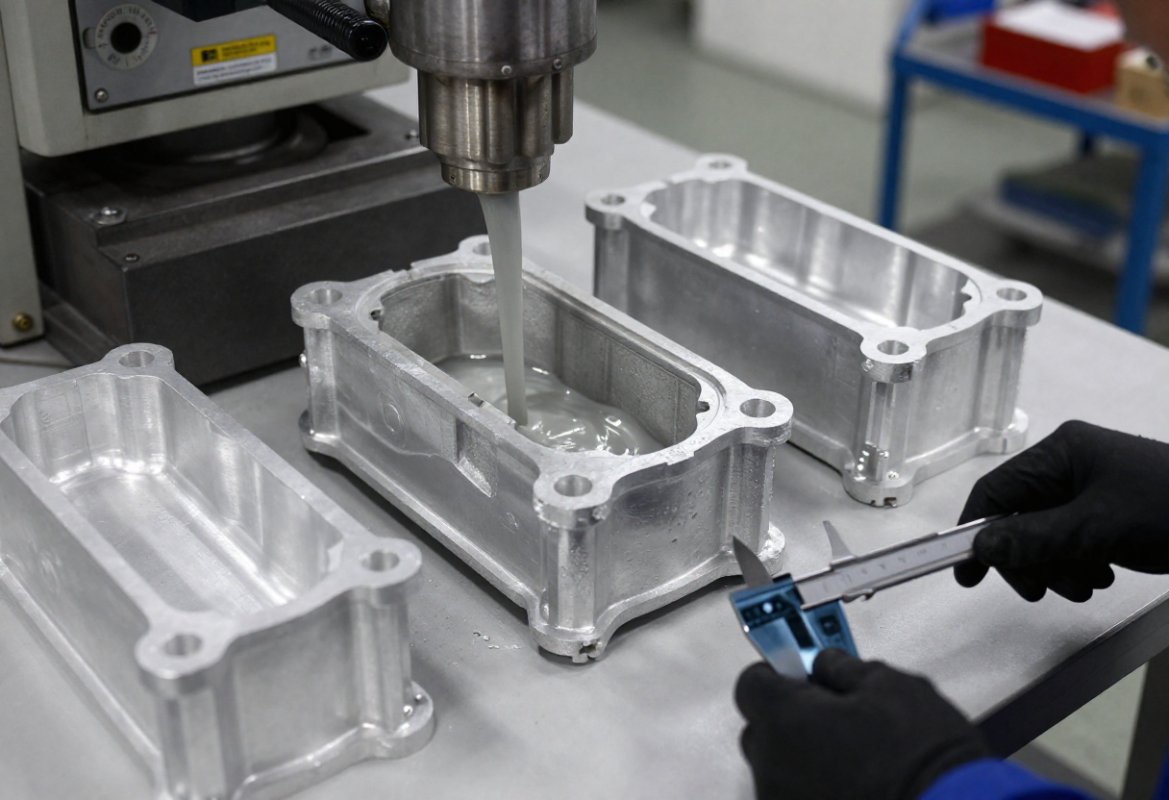

Sand & Gravity Casting

What We Make

Investment Castings

Precision lost‑wax castings for aerospace, medical and power components that require fine geometry, thin walls and excellent surface finish.

Sand & Gravity Castings

Large structure castings, pump housings, engine blocks and heavy‑section parts where tooling flexibility and cost are primary drivers.

Closed‑Die Forgings

Forged components offering superior grain flow, fatigue strength and mechanical performance for critical load‑bearing parts.

Investment Casting (Lost‑Wax)

Ideal for complex geometries and thin‑wall features, investment casting creates repeatable, high‑quality parts with minimal finish machining. We control wax tooling, ceramic shell build, burnout cycles and controlled melt chemistry to meet tight tolerances.

Use cases

Turbine blades, precision pump components, intricate housings and medical implants.

Sand & Gravity Casting

Flexible for large and medium parts, sand casting uses expendable sand molds for quick iterations. Gravity casting is used for controlled fill of moderate complexity parts with good surface finish and predictable mechanical properties.

Advantages

Lower tooling cost, quick turnaround for prototypes and ability to cast large sections not suitable for investment methods.

Closed‑Die Forging

Forging produces parts with optimized grain structure and superior mechanical properties. We provide hot and warm forging, flash trimming, precision forging dies and downstream heat treatment for strength and toughness requirements.

Typical forged parts

Connecting rods, flanges, shafts, high‑load brackets and structural forgings for automotive, aerospace and heavy equipment.

Gravity & Low‑Pressure Die Casting

Low‑pressure and gravity fill techniques reduce turbulence and porosity for castings requiring better internal integrity than typical high‑pressure casting, particularly for aluminum structural housings.

When to use

When reduced porosity and improved mechanical performance are needed without the expense of investment tooling for large parts.

Alloys, Metallurgy & Material Guidance

We work with cast irons, ductile iron, aluminum alloys (A356, ADC12), stainless steels, carbon steels, cobalt/ni-based alloys and special alloys per customer requirements. Metallurgical oversight includes melt chemistry control, inoculation, and heat treatment strategies to achieve mechanical and fatigue targets.

Quality metallurgy

Microstructure analysis, hardness testing, tensile testing and metallurgical reporting are provided as part of qualification when required.

Tooling, Patterns & Die Engineering

Tooling services include pattern making (wood, epoxy, 3D printed patterns), investment wax tool sets, sand pattern masters, and forged die design. We simulate gating and riser systems, perform fill/solidification simulation and iterate tooling during prototype runs to ensure consistent casting quality.

Tool lifecycle

Tool maintenance plans, spare cores and refurbishment strategies to preserve lead times and part consistency across production runs.

Secondary Machining, Heat Treat & Surface Finish

After casting or forging we offer CNC machining, EDM, grinding, hole finishing, tapping, and precision face milling. Heat treatment, stress relieving, shot peen, shot blasting and surface coatings (paint, powder, plating, anodize where applicable) are available to prepare parts for assembly.

Production readiness

We deliver finished parts with FAI, material certificates, dimensional inspection and assembly-ready features to minimize downstream integration work.

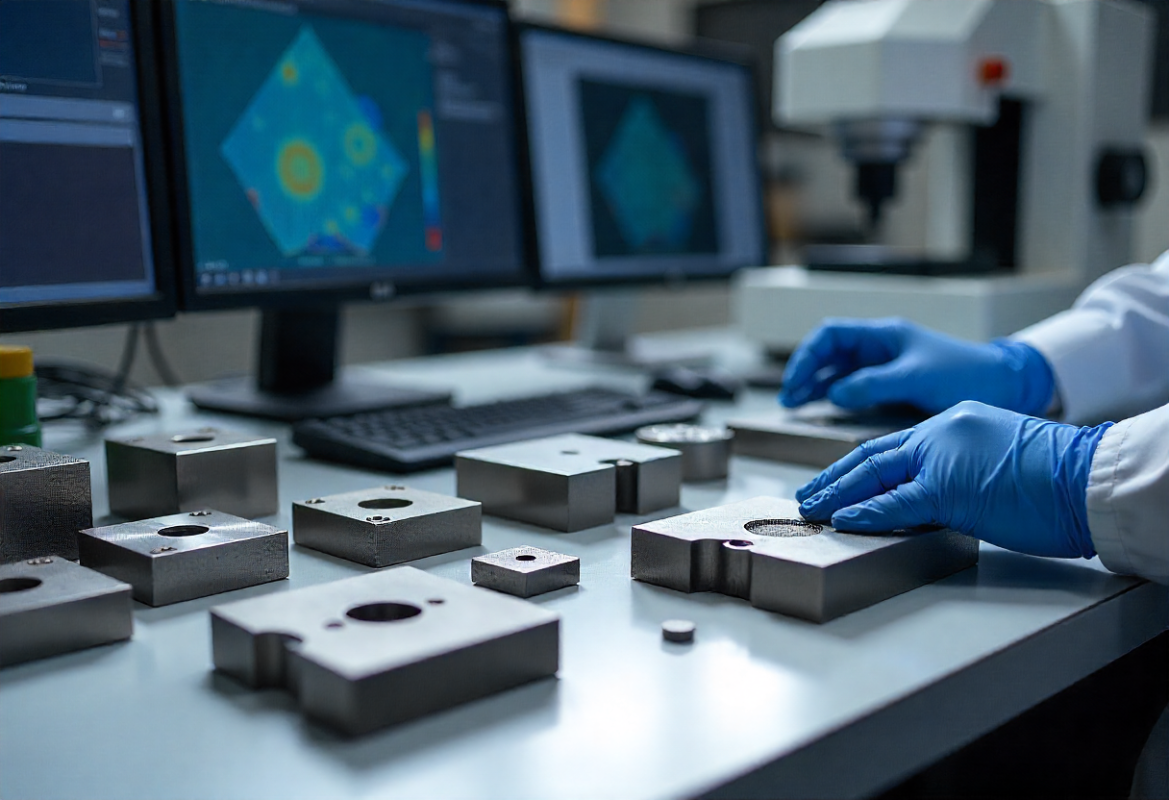

Inspection, NDT & Traceability

Our lab supports CMM inspection, visual and dimensional checks, hardness testing, metallography, X‑ray/CT for porosity, dye penetrant and ultrasonic testing where required. We provide lot traceability, material test reports (MTR), and PPAP/FAI documentation for regulated sectors.

NDT options

CT/X‑ray scanning for internal defects, ultrasonic for thickness and flaw detection, and pressure/leak testing for housings.

Typical Design Guidance & Specifications

Early DFM is critical. Below are representative guidelines to inform initial designs and quotes; final parameters depend on the chosen process and part function.

Part Size

Small precision investment parts to large sand-cast housings (meter scale)

Wall Thickness

Investment: 1–8 mm; Sand: 6+ mm typical for structural parts; forging depends on net-shape

Tolerances

Investment: ±0.1–0.3 mm; Sand: ±0.5–1.5 mm (before machining)

Porosity Control

Vacuum, directional solidification and gating improvements reduce shrink porosity for critical parts

| Parameter | Range / Notes | Recommendation |

|---|---|---|

| Material | Cast irons, steels, aluminum alloys, stainless | Choose alloy for strength, corrosion & thermal requirements |

| Prototype lead time | 2–8 weeks | Depends on process & tooling method |

| Typical finish | As-cast, shot-blast, machined & plated | Specify finished surface and critical datums early |

| Heat treatment | Quench & temper, anneal, solution treat | Specify mechanical targets to define heat treat cycle |

Applications

Automotive & Powertrain

Reduce junction temperatures in SiC/IGBT stacks with thin spreaders to meet compact inverter constraints.

Power Electronics & HVAC

Robust enclosures, pump housings, valve bodies and thermal management components.

Aerospace & Defense

Investment castings for complex aerospace parts and forged components for highly stressed structures.

Representative Projects

Investment Cast Turbine Component

Precision alloy investment casting with tight tolerances and post‑machining for critical aerodynamic surfaces.

Forged Yoke for Heavy Equipment

Closed‑die forged part with heat treatment and shot peen to meet fatigue life requirements; achieved volume targets with automated trimming and machining.

Frequently Asked Questions

Which process provides the best fatigue life?

Closed‑die forging typically yields the best fatigue and mechanical properties due to controlled grain flow — ideal for high‑load, cyclic components.

How do you reduce internal porosity in cast parts?

Use vacuum/low‑pressure casting, directional solidification, optimized gating/risers and proper melt treatment (degassing, inoculation) to reduce porosity.

What documentation do you provide with production runs?

FAI / PPAP, material certifications (MTR), CMM inspection reports, NDT reports (X‑ray/CT, ultrasonic), heat treatment records and lot traceability as required.

Ready to Start a Casting or Forging Project?

Upload your drawings or STEP files and specify target volumes and mechanical requirements. We’ll recommend the optimal process (investment, sand, gravity or forging), tooling approach and a prototype schedule — typically within 24 business hours.