Rubber & Silicone Molded Parts LSR, Compression & Transfer Molding

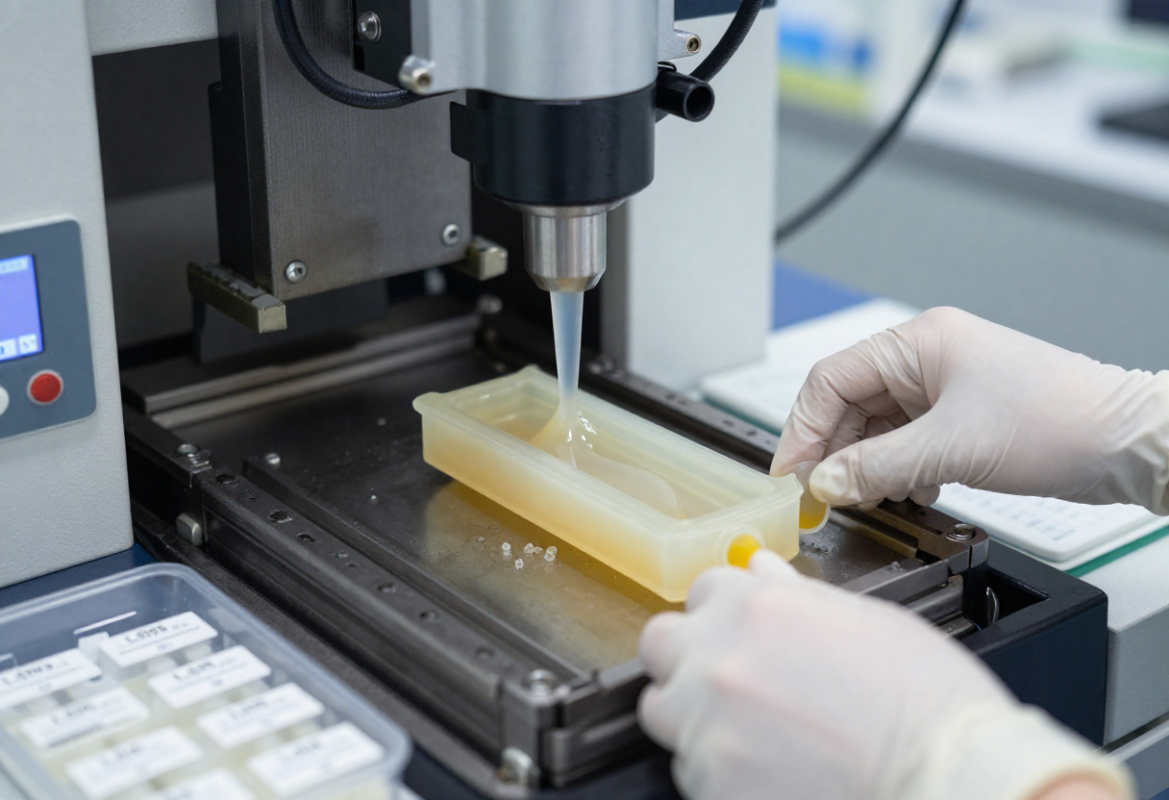

We manufacture high‑quality elastomer components — seals, gaskets, overmolds, boots, diaphragms and custom molded parts — using LSR injection, compression and transfer molding. From medical-grade LSR to durable EPDM and FKM seals, our tooling and process controls deliver repeatable parts with traceable materials and validation testing.

- LSR injection molding for medical, food and high‑precision applications

- Compression & transfer molding for large volumes and engineered elastomers

- Insert molding, overmolding, post‑cure ovens, trim automation and clean‑room assembly

LSR Injection

Compression & Transfer

Trim & Assembly

What We Make

LSR & Liquid Silicone Molding

Compression & Transfer Molding

Overmolding & Insert Molding

LSR Injection Molding

Typical LSR deliverables

- Medical‑grade LSR with traceable lot MTRs

- High cosmetic finish (glistening control, texture options)

- Automated degating and post‑cure for dimensional stability

Compression & Transfer Molding

Typical use cases

- EPDM and NBR seals for automotive & HVAC

- FKM (Viton) components for chemical resistance

- Large diaphragms, gaskets and molded boots

Materials & Typical Properties

Key material characteristics

Temperature Range

Silicone/LSR: -60 °C to +200 °C; FKM: up to +250 °C (application dependent)

Durometer

Shore A 10 — 90 typical; micro‑hardness ranges available for specific compounds

Compression Set

Varies by compound — we select low compression set materials for static seals

Chemical Resistance

FKM for fuel/chemical resistance; EPDM for weather & steam; custom compounds for specific fluids

Tooling, Cavities & Maintenance

Tool life & maintenance

Inspection, Material Certificates & Testing

Cleanroom & traceability

Qualification & Reliability

Documentation

Applications

Automotive & EV Components

Sealed housings, connectors, gaskets, cable boots and trim components with automotive-grade processes.

Medical & Healthcare

Biocompatible LSR parts, sterilizable plastics and clean assembly workflows.

Telecom & Consumer

Overmolded grips, keypads, gaskets and weather seals for outdoor equipment and consumer products.

Case Studies

Medical LSR Valve Seal

EV Coolant Hose Boot

Frequently Asked Questions

How do I choose between LSR and silicone solid molding?

What tolerances can you hold for molded elastomers?

Do you support clean‑room molding and assembly?

Start Your Elastomer Project

Upload your drawings, desired compound and target volumes. We’ll return DFM feedback, material recommendations and a prototype plan typically within 24 business hours.