Precision CNC Machined Parts Metal & Engineering Plastics

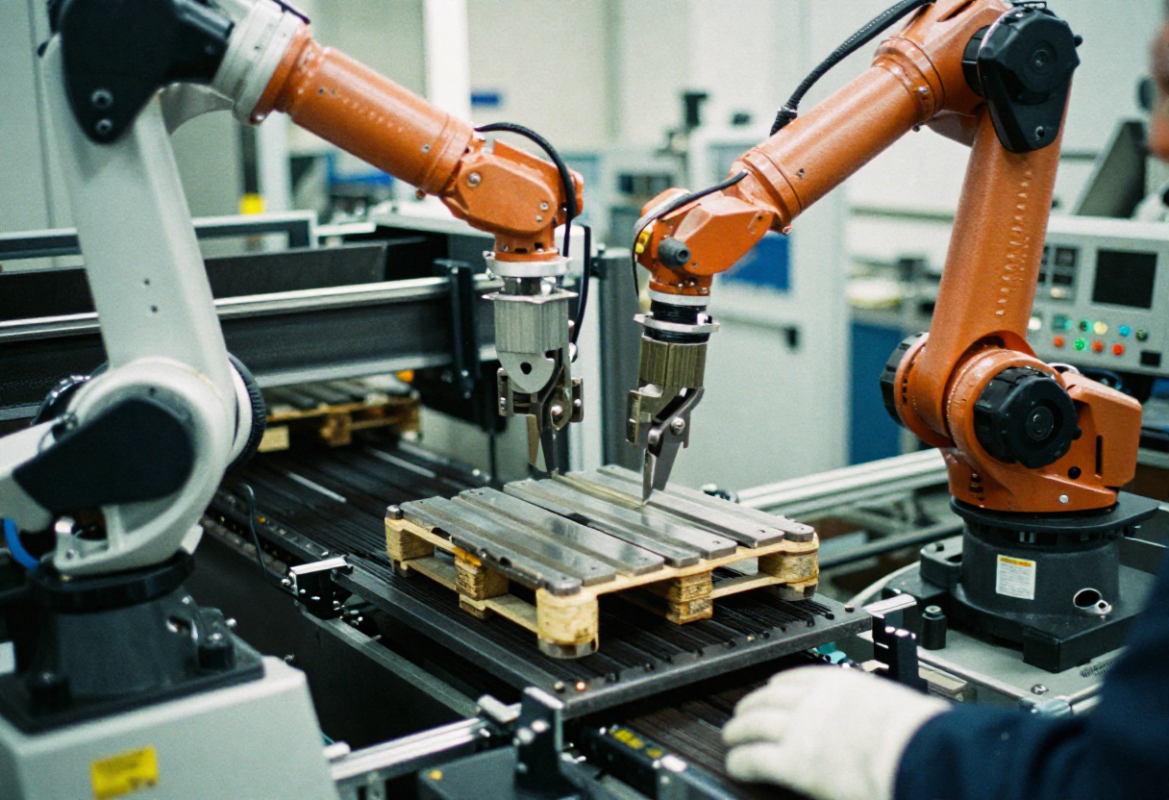

We produce precision CNC parts using 3‑5 axis milling, multi‑axis turning, Swiss machines and automated cells. Our parts serve thermal assemblies, power electronics, medical devices and aerospace where tight tolerances, complex geometry and traceable quality are essential.

- 5‑axis milling, multi‑spindle Swiss turning, live tooling and EDM

- Tight tolerances (typical ±0.01 mm, specialty ±0.005 mm) and fine surface finishes

- Prototype → NPI → scalable production with in‑process inspection and CMM reporting

5-Axis Milling

Swiss Turning

CMM & Inspection

Core Capabilities

Multi‑Axis Milling

Turning & Swiss Machining

EDM, Grinding & Secondary Operations

Automation & High‑Volume Cells

Materials We Machine

Material selection & guidance

Tolerances & Surface Finish

GD&T & critical features

Typical Process Flow

RFQ & DFM review

material, tolerances, surface finish, cost opportunities

Prototype & validation

quick‑turn CNC or soft tooling samples

Process development

fixture design, toolpaths, first‑article setup

Production & inspection

automated cells or manual lines with SPC

Assembly & finishing

plating, anodize, polishing, assembly and testing

Inspection & Metrology

Quality systems

Finishing & Secondary Processes

Thermal and functional treatments

Applications

Power Electronics & Thermal Assemblies

Machined heatsink housings, busbar clamps and precision mounting features for high‑power modules.

Medical Devices

Biocompatible components, sterile packaging and precision parts with tight traceability.

Aerospace & Defense

Lightweight structural parts, titanium machined components and high‑reliability assemblies.

Selected Case Studies

High‑Precision Aluminum Fixture for EV Inverter